Method for processing phosphate rock tailings and producing magnesium-containing calcium carbonate

A technology of phosphorus tailings and calcium carbonate, which is applied to the treatment of calcium carbonate/strontium/barium, magnesium carbonate, phosphate materials, etc., to achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

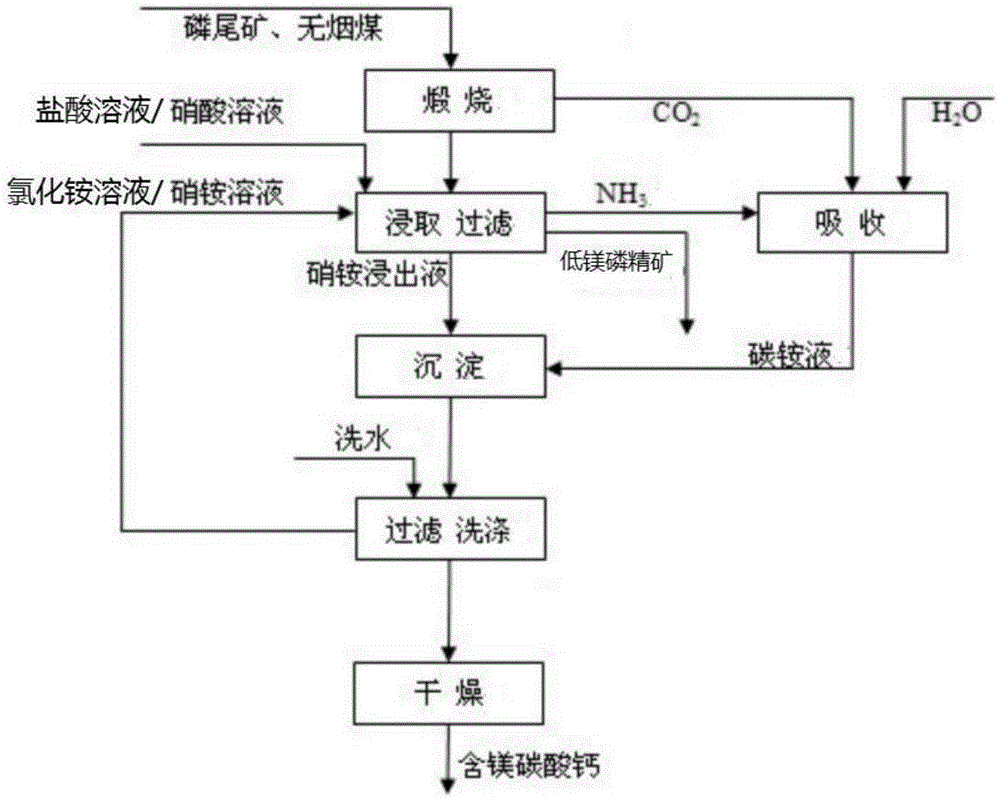

Image

Examples

Embodiment 1

[0065] A method for processing phosphate rock tailings and producing magnesium-containing calcium carbonate, comprising the following steps:

[0066] (1) Calcination and digestion: the phosphorus tailings are placed in a calciner, calcined at a temperature of 950°C for 60 minutes, and then subjected to water digestion; the water digestion is carried out with 85°C hot water, and the amount of water is 100g of phosphorus tailings use 100ml of water;

[0067] (2) Composite leaching: place the digested phosphorus tailings in a leaching tank, then add a 30% ammonium nitrate solution and a 60% nitric acid solution, and stir for 60 minutes at a temperature of 85°C; ammonium nitrate The dosage is to add 300g per 100g of phosphorous tailings, and the amount of nitric acid solution is to add 20g per 100g of phosphorous tailings;

[0068] (3) Separation: filter and wash the slurry after the leaching treatment in step 2 to obtain leach residue and leach solution; dry the filter residue a...

Embodiment 2

[0073] A method for processing phosphate rock tailings and producing magnesium-containing calcium carbonate, comprising the following steps:

[0074] (1) Calcination and digestion: the phosphorus tailings are placed in a calciner, calcined at a temperature of 900°C for 75 minutes, and then subjected to water digestion; the water digestion is carried out with 60°C hot water, and the amount of water is 110ml of water is used for 100g of phosphorus tailings;

[0075] (2) Composite leaching: place the digested phosphorus tailings in a leaching tank, then add a 10% ammonium nitrate solution and a 50% nitric acid solution, and stir for 70 minutes at a temperature of 80°C; ammonium nitrate The dosage is to add 250g per 100g of phosphorous tailings, and the amount of nitric acid solution is to add 18g per 100g of phosphorous tailings;

[0076] (3) Separation: filter and wash the slurry after the leaching treatment in step 2 to obtain leach residue and leach solution; dry the filter r...

Embodiment 3

[0081] A method for processing phosphate rock tailings and producing magnesium-containing calcium carbonate, comprising the following steps:

[0082] (1) Calcination and digestion: the phosphorus tailings are placed in a calciner, calcined at a temperature of 1100°C for 45 minutes, and then subjected to water digestion; the water digestion is carried out with 100°C hot water, and the amount of water is 100g phosphorous tailings use 90ml water;

[0083](2) Composite leaching: place the digested phosphorus tailings in a leaching tank, then add 50% ammonium nitrate solution and 80% nitric acid solution, and stir for 50 minutes at a temperature of 85°C; ammonium nitrate The dosage is to add 350g per 100g of phosphorous tailings, and the amount of nitric acid solution is to add 22g per 100g of phosphorous tailings;

[0084] (3) Separation: filter and wash the slurry after the leaching treatment in step 2 to obtain leach residue and leach solution; dry the filter residue at 110° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com