Vehicle speed control mechanism for bullet loading vehicle

A technology for vehicle speed control and vehicle use, which is applied to the layout of power plant control mechanisms, vehicle components, transportation and packaging, etc. It can solve problems such as poor driving stability, body vibration, poor ride comfort, etc., achieve a high degree of automation, and solve the sense of frustration Strong, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

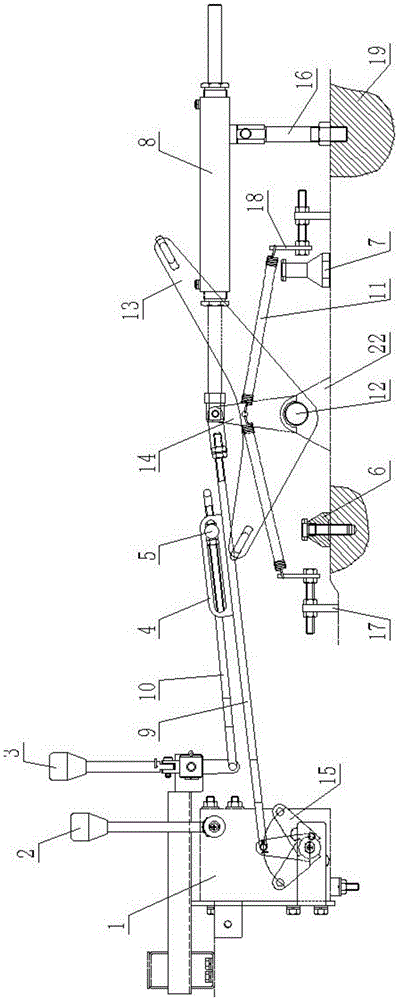

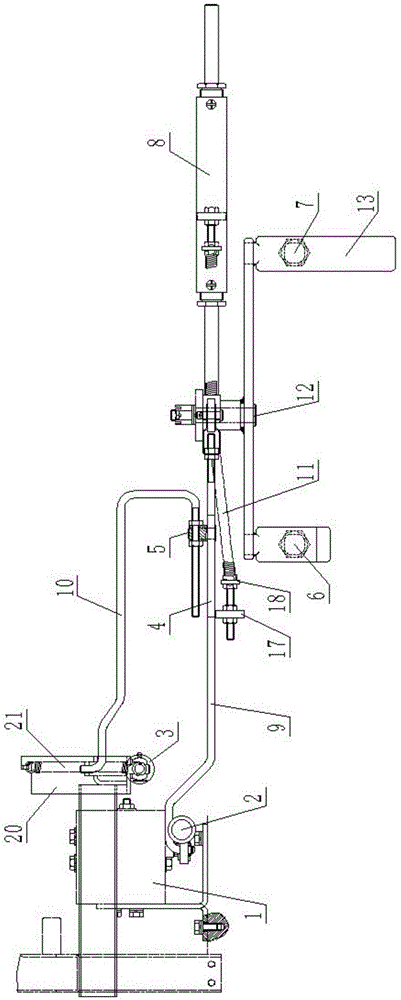

[0017] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

[0018] Such as Figure 1-2 As shown, the speed control mechanism for a loading vehicle provided by the present invention includes a pedal 13, the middle part of the top end of the pedal 13 is hinged on the pedal seat 22 through the pedal shaft 12, the pedal seat 22 is fixed on the vehicle frame 19, and the middle part of the pedal shaft 12 is fixed There is a vertically arranged swing arm 14, the top of the swing arm 14 is hinged with a drive rod 9, the other end of the drive rod 9 is hinged on the lever 15 outside the throttle controller 1, and the drive rod 9 is fixed with a vertically arranged speed limiter. Slot plate 4; the accelerator controller 1 is provided with a brake handle 2 and a cover plate 20, the front end of the cover plate 20 is hinged to the speed-limiting ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com