Preparation method and application of low temperature denitration Ni-based composite oxide cellular monolithic catalyst

A composite oxide and integral catalyst technology, applied in the field of environmental catalytic purification, can solve problems such as erosion, catalyst blockage, and reduced catalyst service life, and achieves a simple preparation process, wide low-temperature denitration performance, and good water and sulfur resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Synthesis of Ni-based composite oxide powder catalyst precursor by uniform co-precipitation method

[0022] (1) Weigh 686.0gMn(CH 3 COO) 2 2H 2 O, 348.9gNi(NO 3 ) 2 2H 2 O, 99.8gCu(CH 3 COO) 2 2H 2 O, 104.9gFe(NO 3 ) 3 9H 2 O, 124.5gCo(CH 3 COO) 2 2H 2 O, 164.5gCe(NH 4 ) 2 (NO 3 ) 6 , dissolved in 10L of deionized water, and stirred until the solution was completely clear to prepare a mixed salt solution. Weigh 961.0gCO(NH 2 ) 2 Dissolve in 10L deionized water and stir until the solution is completely clear.

[0023] (2) Mix the salt solution and CO(NH 2 ) 2 The solution was transferred to a powder catalyst preparation reactor, mixed evenly, and reacted at 60° C. under continuous stirring for 5 hours to obtain a yellow-green product.

[0024] (3) The yellow-green product was washed several times with deionized water, centrifuged, and dried at 70° C. for 12 hours to obtain a Ni-based composite oxide catalyst powder precursor.

Embodiment 2

[0025] Embodiment 2: Preparation of Ni-based composite oxide honeycomb monolithic catalyst

[0026] (1) Take 240.0g of the Ni-based composite oxide catalyst powder precursor synthesized in Example 1 and mix evenly with 30.0g of pseudo-boehmite, 15g of silicon oxide, and 15g of turnip powder, and mix 120ml of dilute Nitric acid solution (6.8vol.%) was added to the above mixture and kneaded for 4h. Transfer the kneaded plastic material to a vacuum mud mixer to remove excess moisture and gas from the material. The material obtained after mud refining is put into the extruder, and the monolithic catalyst green body is extruded by a honeycomb stainless steel die.

[0027] (2) Air-dry the extruded integral catalyst body in a cool place, and then dry it at 70°C for 24h. After the integral catalyst body is fully dried, it is calcined at 550°C for 4h, and the heating rate is 10°C / min to prepare a Ni-based composite oxide honeycomb monolithic catalyst.

Embodiment 3

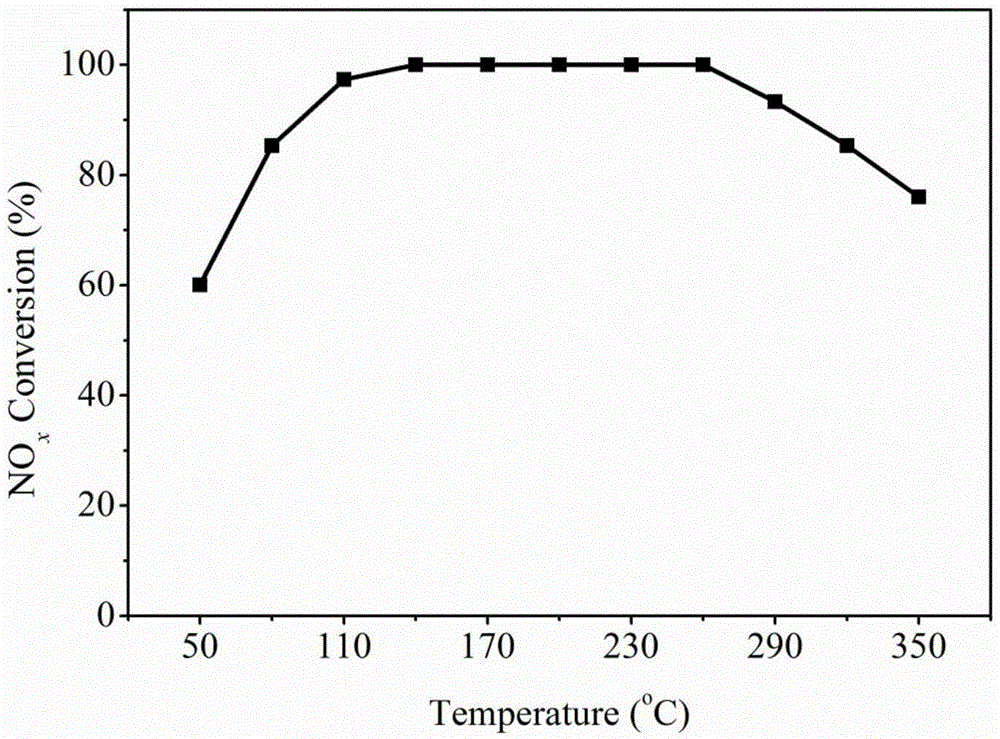

[0028] Embodiment 3: the test of overall catalyst reactivity changing with reaction temperature

[0029] A honeycomb monolithic catalyst with a length of 50 mm and an outer diameter of 12 mm was placed in a flue gas simulation reaction device to test the NO removal effect of the monolithic catalyst under different temperature conditions. The composition of the simulated flue gas was 480ppmNO, 480ppmNH 3 , 15vol.%O 2 , He is the balance gas, and the air velocity of the simulated flue gas is 6,500h -1 . Ni-Based Composite Oxide Honeycomb Monolithic Catalysts for NO x The change curve of conversion rate with temperature is as follows: figure 1 shown.

[0030] The reaction results show that with the increase of the reaction temperature, the NO of the monolithic catalyst x The conversion rate gradually increased. The Ni-based composite metal oxide honeycomb monolithic catalyst has a specific wide temperature operating window, and its NO in the temperature range of 80-320 ° C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com