Solid oxide fuel cell apparatus

A solid oxide, fuel cell technology, used in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problem of heat exchange performance of heat exchangers (heat recovery performance is reduced, time-consuming, cannot be rapidly improved. Problems such as the operating temperature of the solid oxide fuel cell device to achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

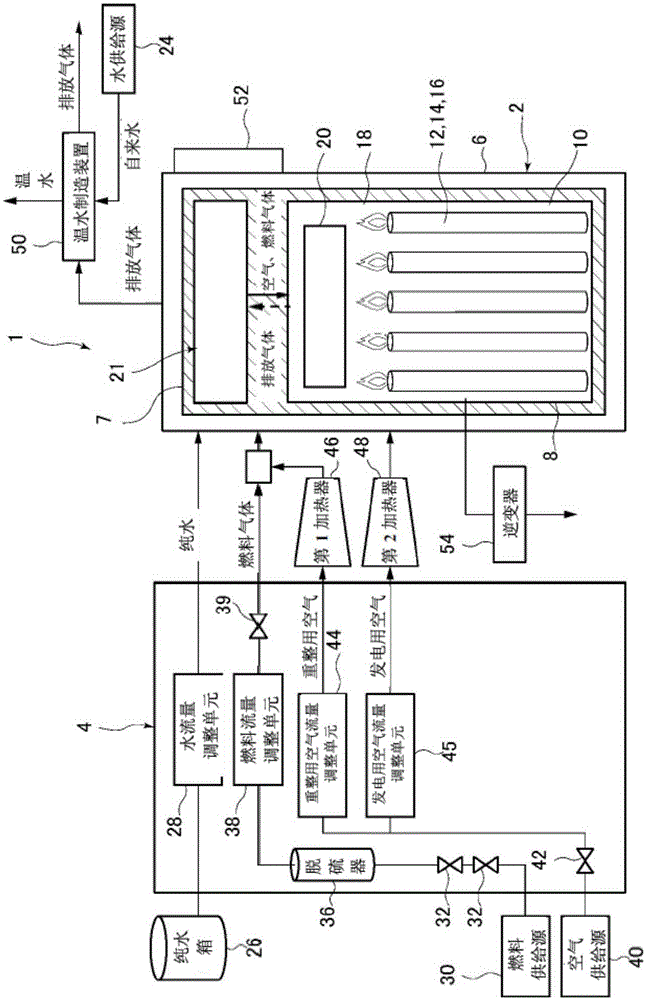

[0071] First, a solid oxide fuel cell device (SOFC) according to a first embodiment of the present invention will be described.

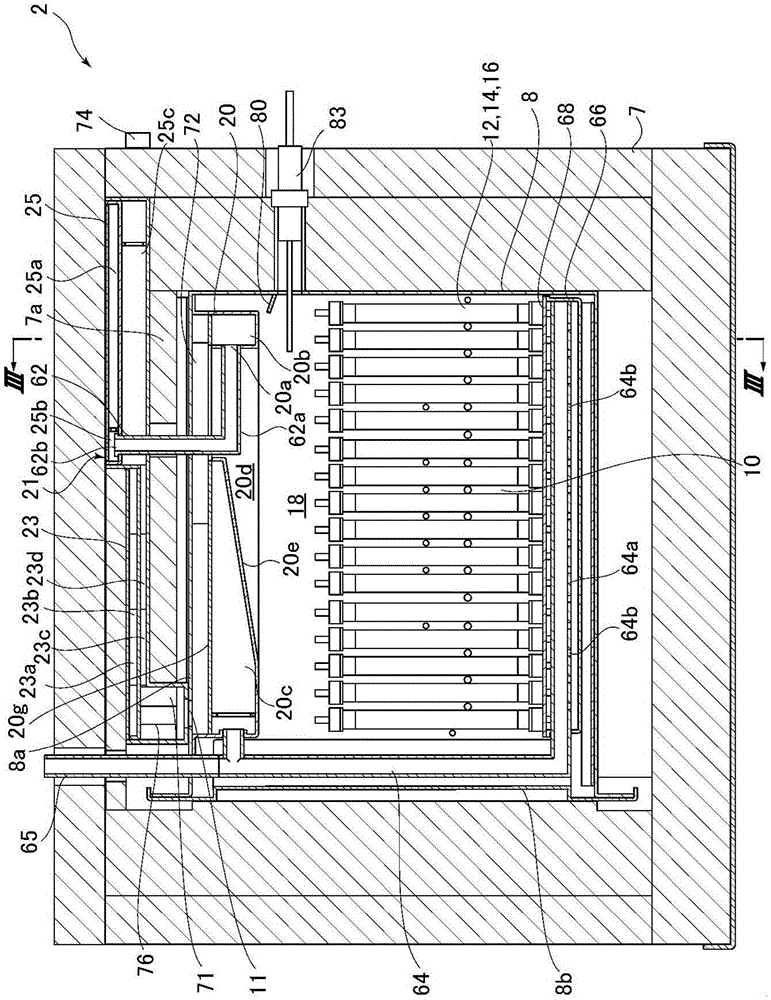

[0072] figure 1 It is a diagram showing the overall configuration of the solid oxide fuel cell device according to the first embodiment of the present invention. as it should figure 1 As shown, the solid oxide fuel cell device 1 according to the first embodiment of the present invention includes a fuel cell module 2 and an auxiliary unit 4 .

[0073] The fuel cell module 2 includes a case 6 , and a metal module case 8 is built in the case 6 via a heat insulating material 7 . In the power generation chamber 10, which is the lower part of the module case 8 in this closed space, there are arranged fuel cells that perform power generation reactions using fuel gas and oxidant gas (hereinafter appropriately referred to as "air for power generation" or "air"). Collective 12. The fuel cell assembly 12 includes nine fuel cell stacks 14 (refer to Figure...

no. 2 Embodiment approach

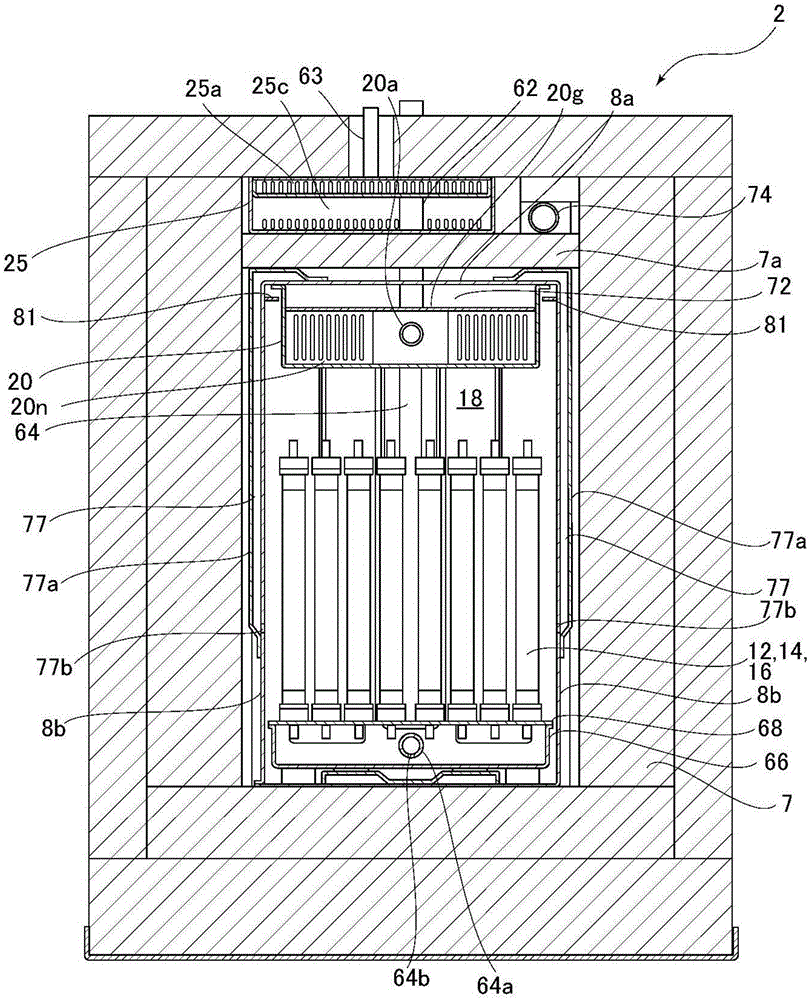

[0168] Next, a solid oxide fuel cell device (SOFC) according to a second embodiment of the present invention will be described.

[0169] In addition, descriptions of the same configurations and effects as those of the above-mentioned first embodiment will be appropriately omitted below, and only configurations and effects that are different from those of the first embodiment will be described. That is, configurations and effects not particularly described here are the same as those of the first embodiment.

[0170] Figure 14 It is a diagram showing the overall configuration of a solid oxide fuel cell device according to a second embodiment of the present invention. as it should Figure 14 As shown, the solid oxide fuel cell device 1X of the second embodiment includes a fuel cell module 2X instead of the fuel cell module 2 shown in the first embodiment.

[0171] Although the above-mentioned fuel cell module 2 of the first embodiment is provided with the heat exchange module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com