A kind of preparation method of cobalt manganese oxygen catalyst

A cobalt manganese oxide catalyst, manganese sulfate technology, applied in fuel cell type half cells and primary cell type half cells, nanotechnology for materials and surface science, electrical components, etc., can solve the high cost and disadvantage of precious metals. Practical application and other issues, to achieve the effects of cheap raw materials, improved electrochemical performance, simple and environmentally friendly preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of cobalt-manganese-oxygen catalyst, comprising the following steps:

[0038] 1) Dissolve potassium permanganate and manganese sulfate in 80mL water at a molar ratio of 2:3 and mix evenly, react at room temperature for 6h, filter and dry to obtain amorphous MnO 2 powder;

[0039] 2) the resulting amorphous MnO 2 The powder and cobalt chloride were dissolved in 10mL of water at a molar ratio of 2:1, stirred for 15min, and mixed uniformly to obtain a mixed solution I;

[0040] 3) Mix 0.02mol of sodium borohydride and 0.1mmol of sodium hydroxide, dissolve in 10mL of water, stir for 15min, and mix uniformly to obtain mixed liquid II;

[0041] 4) Add the obtained mixed solution II into the mixed solution I, and react under stirring conditions, the stirring temperature is 25° C., and the stirring time is 10 min. After the reaction is completed, filter to obtain the final product.

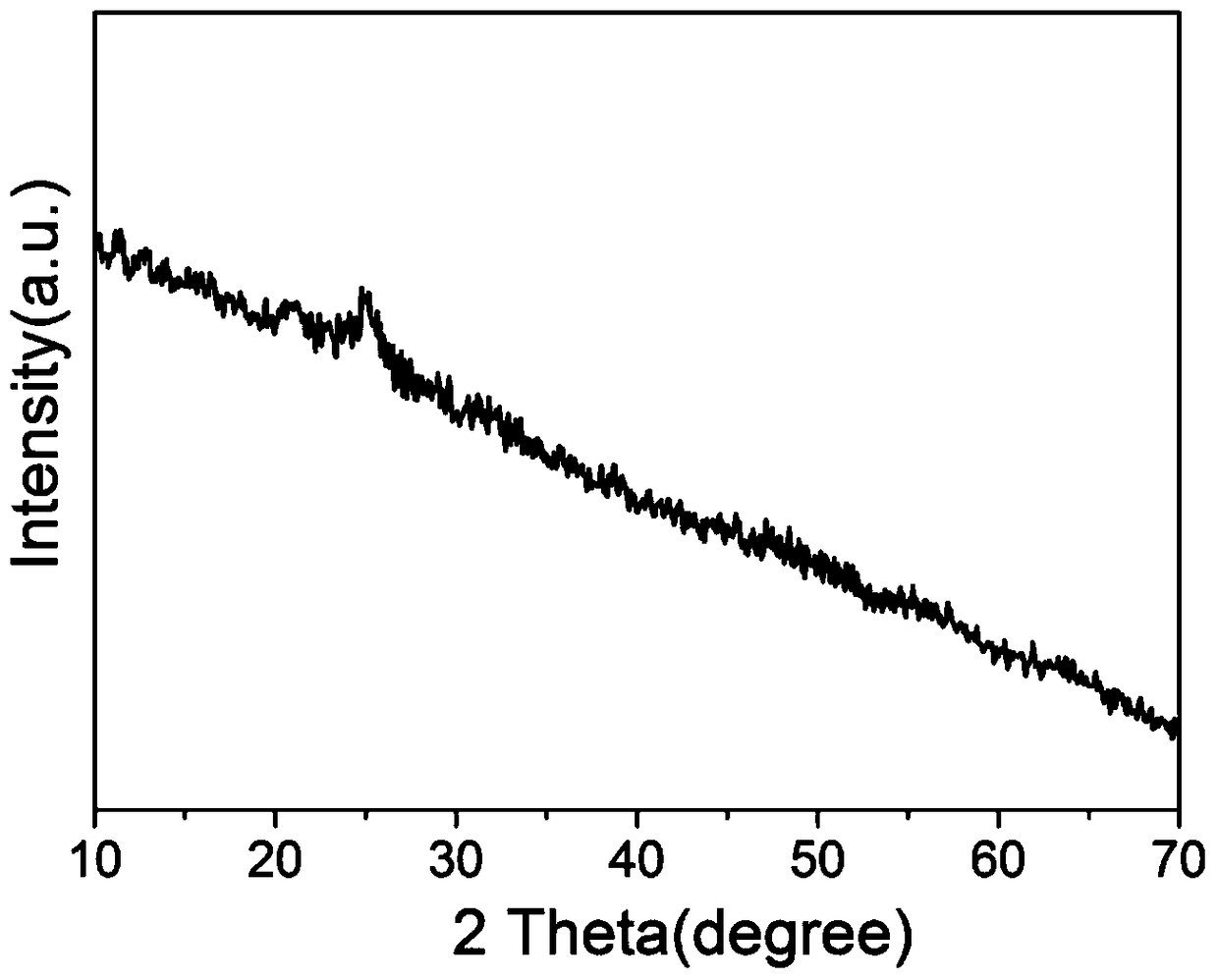

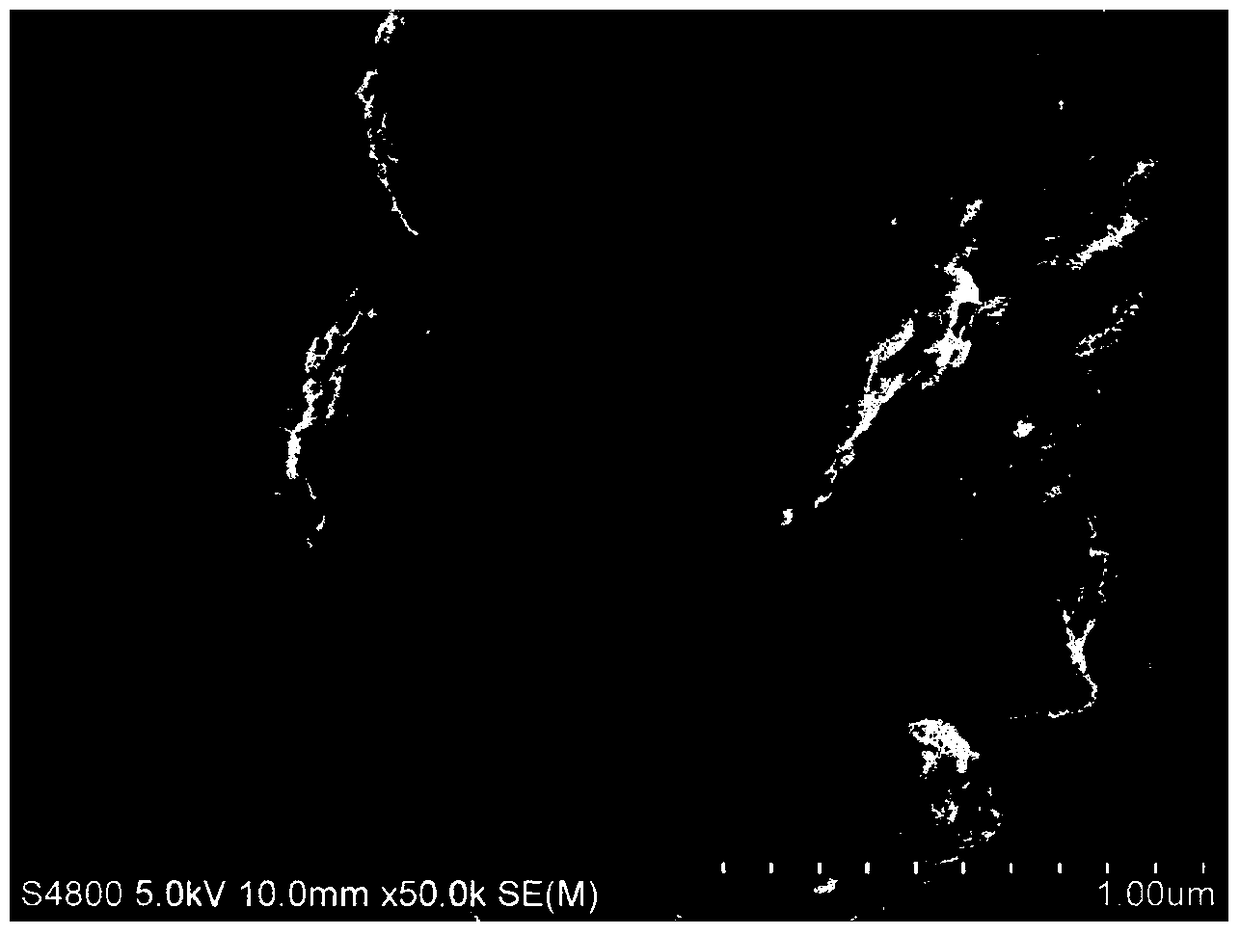

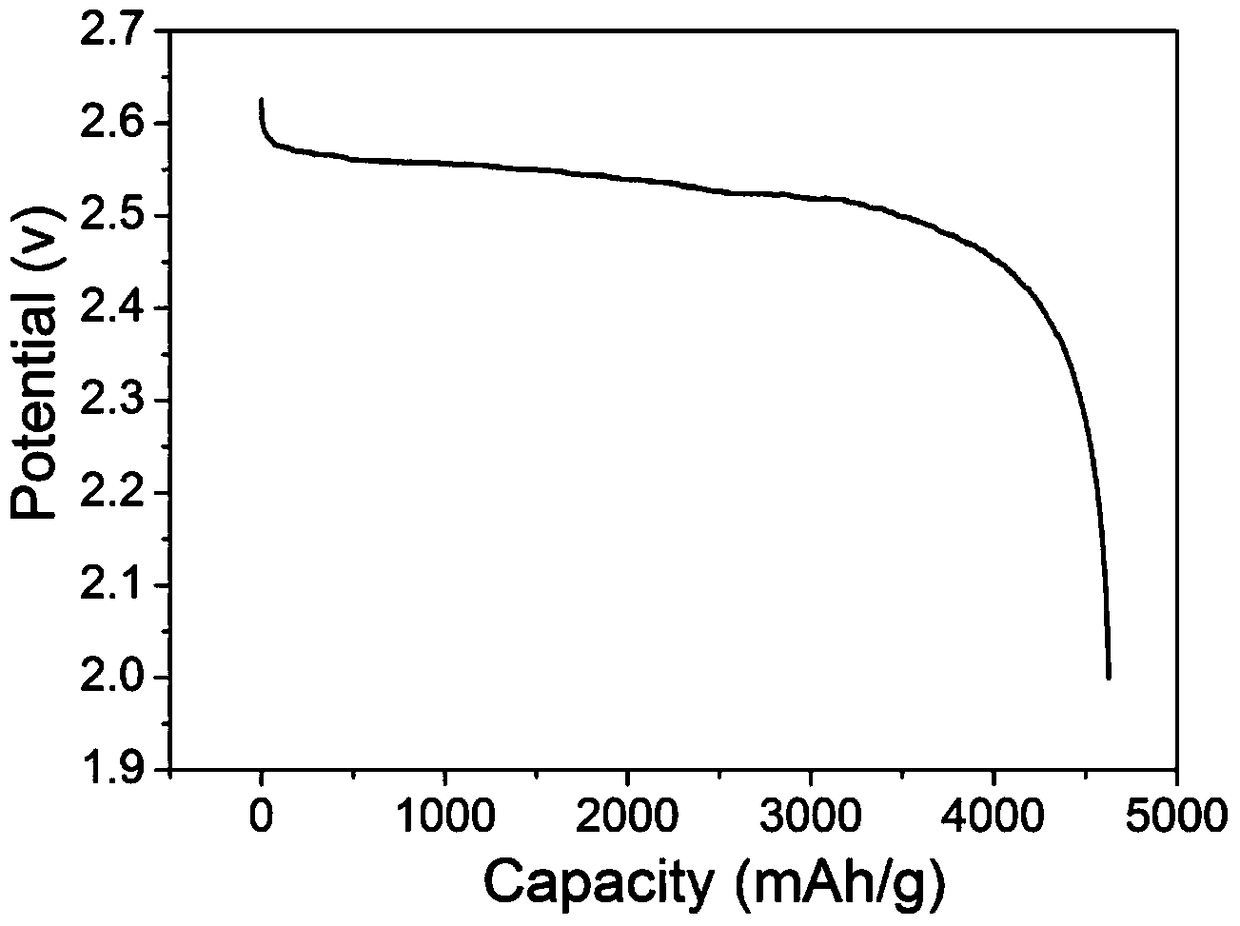

[0042] The product obtained in this embodiment is analyzed by X-ray dif...

Embodiment 2

[0045] A preparation method of cobalt-manganese-oxygen catalyst, comprising the following steps:

[0046] 1) Dissolve potassium permanganate and manganese sulfate in 80mL water at a molar ratio of 2:3 and mix evenly, react at room temperature for 6h, filter and dry to obtain amorphous MnO 2 powder;

[0047] 2) the resulting amorphous MnO 2 The powder and cobalt chloride were dissolved in 10 mL of water at a molar ratio of 2:1, stirred for 15 min, and mixed uniformly to obtain solution I;

[0048] 3) Mix 5mmol of sodium borohydride and 0.1mmol of sodium hydroxide, dissolve in 10mL of water, stir for 15min, and mix well to obtain a mixture II;

[0049] 4) The obtained solution II was added to the mixed solution I, and the reaction was carried out under the condition of stirring, the stirring temperature was 25° C., and the stirring time was 10 min. After the reaction was completed, the cobalt-manganese-oxygen catalyst was obtained by filtering.

[0050] The product obtained i...

Embodiment 3

[0053] A preparation method of cobalt-manganese-oxygen catalyst, comprising the following steps:

[0054] 1) Dissolve potassium permanganate and manganese sulfate in 80mL water at a molar ratio of 2:3 and mix evenly, react at room temperature for 6h, filter and dry to obtain amorphous MnO 2 powder;

[0055] 2) the resulting amorphous MnO 2 The powder and cobalt chloride were dissolved in 10 mL of water at a molar ratio of 2:1, stirred for 15 min, and mixed uniformly to obtain solution I;

[0056] 3) Mix 0.02mol of sodium borohydride and 0.1mmol of potassium hydroxide, dissolve in 10mL of water, stir for 15min, and mix uniformly to obtain a mixture II;

[0057] 4) The obtained solution II was added to the mixed solution I, and the reaction was carried out under the condition of stirring, the stirring temperature was 60° C., and the stirring time was 10 min. After the reaction was completed, the cobalt-manganese-oxygen catalyst was obtained by filtering.

[0058] The product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com