In-situ temperature loading device for neutron diffraction

A technology of in-situ temperature and loading device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem that the measurement process cannot meet the high temperature tensile test, etc., and achieve the effect of small overall structure and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

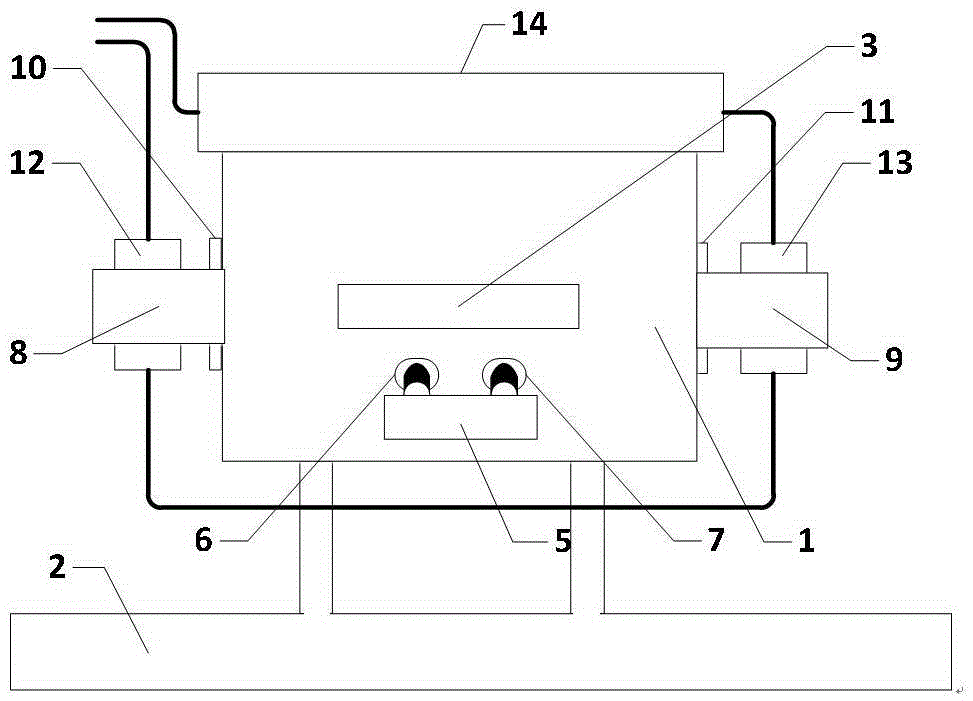

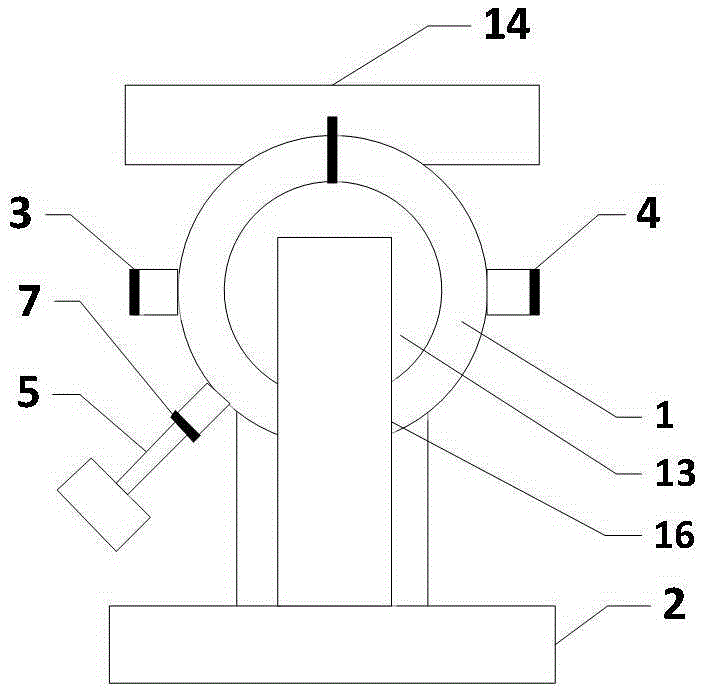

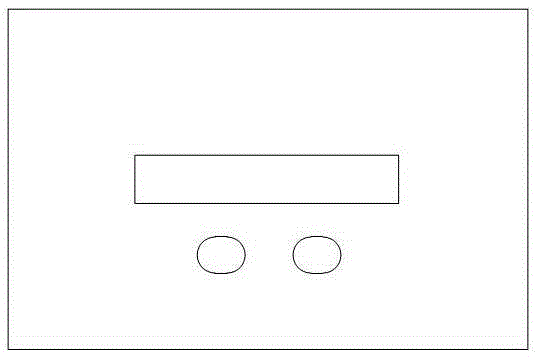

[0025] figure 1 is the front view of the in-situ temperature loading device for neutron diffraction of the present invention; figure 2 It is the right side view of the in-situ temperature loading device for neutron diffraction of the present invention; image 3 It is a front view of the structure of the furnace cavity in the present invention; Figure 4 It is the right side view of the structure of the furnace cavity in the present invention. exist Figure 1 to Figure 5 Among them, an in-situ temperature loading device for neutron diffraction in the present invention includes a furnace cavity 1, a base 2, an incident window plate 3, an exit window plate 4, a high-temperature extensometer 5, a foot A window film 6, and a foot B window film 7, left fixture 8, right fixture 9, left fixture gasket 10, right fixture gasket 11, left cooling water jacket 12, right cooling water jacket 13, upper cooling water jacket 14. The furnace body cavity 1 is provided with a neutron inciden...

Embodiment 2

[0038] The structure of this embodiment is the same as that of Embodiment 1, except that the material of the incident window plate 3 and the exit window plate 4 is made of pure aluminum, the diameter of the left clamp 8 and the right clamp 9 is 40 mm, and internal threads are provided on both sides. The diameter of the furnace body cavity 1 is 20 mm; the diameter of the two fixture holes of the furnace body cavity 1 is 42 mm, and the inner diameter of the furnace body cavity 1 is 45 mm.

[0039] After the above implementation, the present invention can carry out temperature loading on a relatively large metal rod-shaped standard sample with a diameter of 10 mm, and together with an external in-situ mechanical stretching device, can carry out neutron diffraction in-situ on a thermal neutron diffraction spectrometer Neutron measurement experiment in temperature-mechanical complex environment.

Embodiment 3

[0041] The structure of this embodiment is the same as that of Embodiment 2, except that one end of the left side clamp 8 and one end of the right side clamp 9 are respectively connected to the external fixed bracket by threads, and the other end of the left side clamp 8, The other end of the right clamp 9 is connected with the sample.

[0042] After the above-mentioned implementation, the present invention can carry out temperature loading on a relatively large metal rod-shaped standard sample with a diameter of 10 mm, and can carry out neutron measurement experiments under the in-situ temperature environment of neutron diffraction on a thermal neutron diffraction spectrometer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com