Dense construction method at the lower circular arc of the drainage pipe on the sandy soil base

A construction method and technology for drainage pipes, which are applied to the sewer system, waterway system, water supply device, etc., can solve the problems of road surface collapse, the backfill density of the arc under the drainage pipe is difficult to meet the design requirements, etc. Uniformity, avoiding road collapse, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

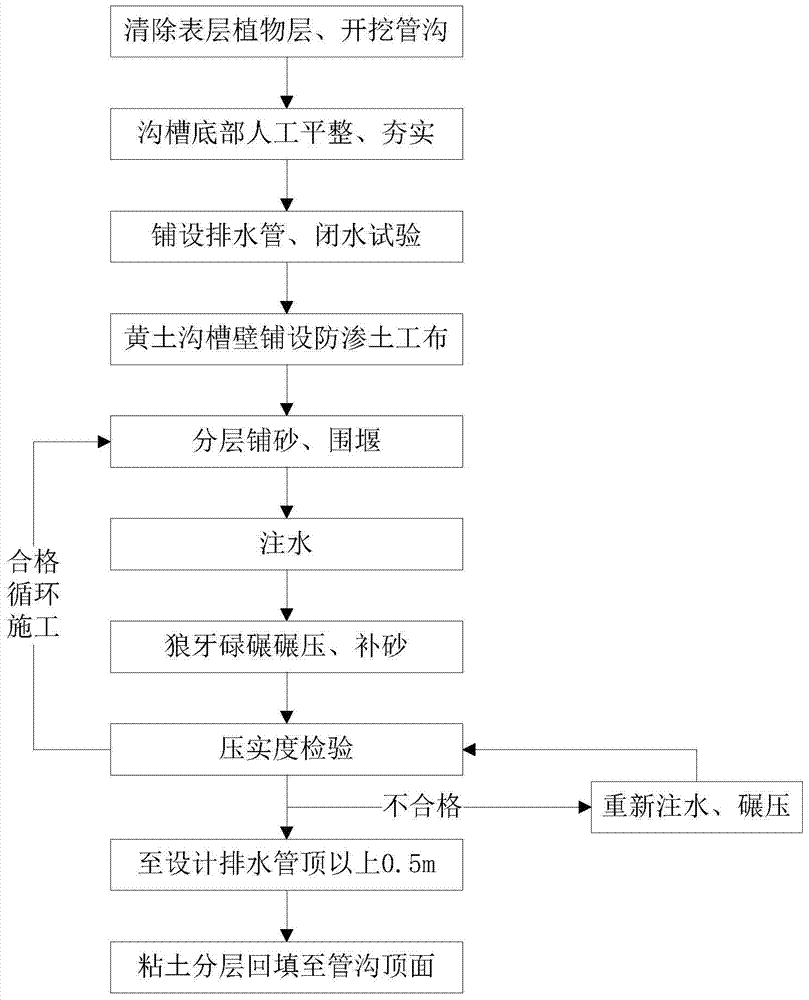

Method used

Image

Examples

Embodiment

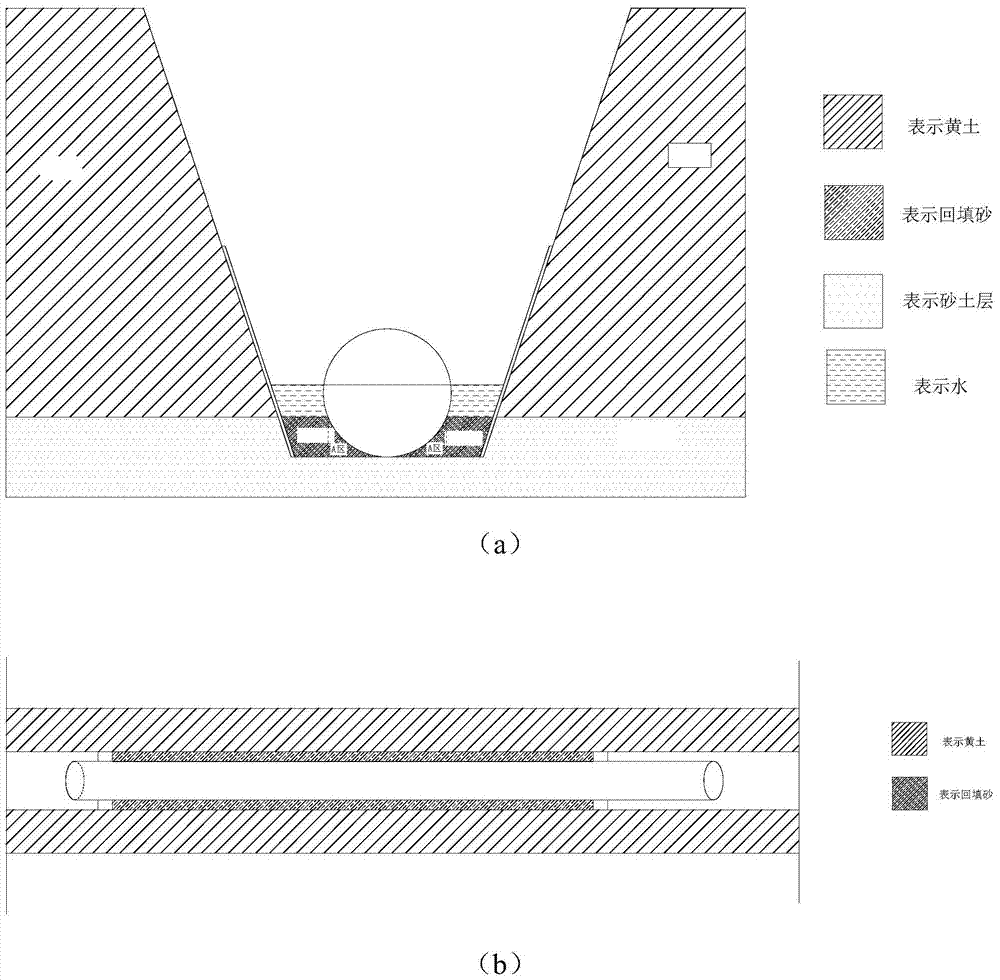

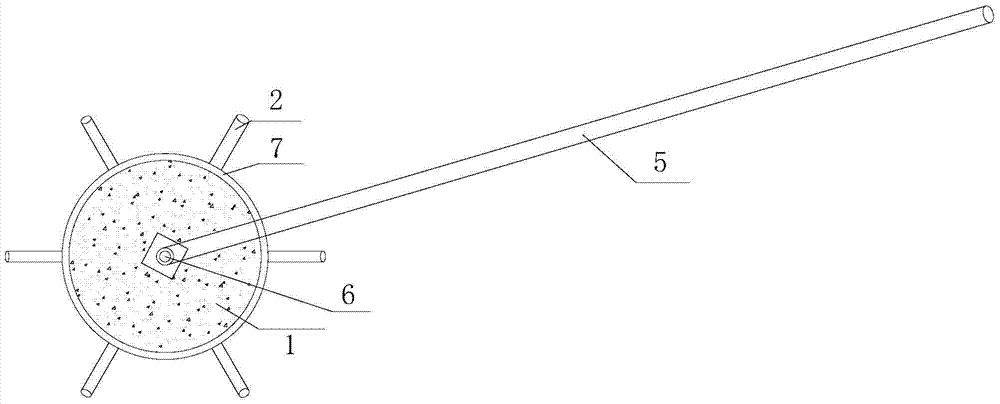

[0049] A municipal road has a length of 401.321m and a planned red line width of 50m. The road grade is the main road of the city, and the bottom of the rainwater and sewage ditch is a thick sand layer with good water permeability. The diameter of the rainwater pipe is di800mm, the excavation width at the bottom of the trench is 1800mm, and a 500mm working face is left on both sides of the pipe; the working face is narrow. The diameter of the sewage pipe is di500mm, the excavation width at the bottom of the trench is 1300mm, and 400mm of working face is left on both sides of the pipe. The original ground elevation: 390.3m, the depth of the trench is 2.7m-4m, and the slope is 0.3%. The upper part of the trench is collapsible loess, and the lower part is sandy soil. The drainage pipe is made of steel belt reinforced polyethylene (PE) spiral corrugated pipe, which is laid at the bottom of the pipe trench whose bearing capacity meets the design requirements. The design requires ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com