A method for preparing wear-resistant superhydrophobic coating using cold spray technology and product thereof

A super-hydrophobic coating, cold spray technology, applied in the direction of pressure inorganic powder coating, etc., to achieve the effect of high deposition rate, broad application prospects, good non-stick performance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

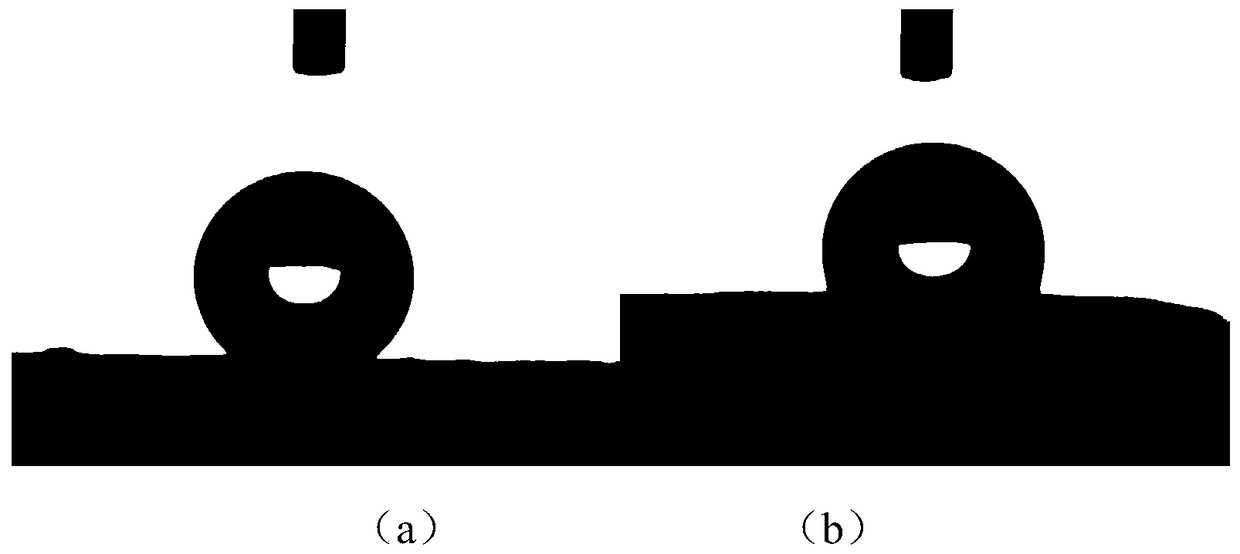

Image

Examples

Embodiment 1

[0033] In the present embodiment, the substrate material is selected as 316 stainless steel with a thickness of 2mm, and the specific preparation method of the wear-resistant superhydrophobic coating is as follows:

[0034] (1) Clean the substrate with acetone, alcohol, and deionized water in sequence, and then use 60-mesh brown corundum sand to roughen the surface of the substrate. The air pressure used for sandblasting is 0.5MPa, and the blasting time is 30s;

[0035] (2) The powder used is titanium dioxide powder modified by low surface energy substances, and the specific preparation method of the titanium dioxide powder modified by low surface energy substances is: adding titanium dioxide powder with an average diameter of 50 microns to ethanol to a concentration of 5% by mass , and then add 5% polytetrafluoroethylene (PTFE, wherein 5% refers to the final concentration of PTFE) in the solution, and stir evenly.

[0036] (3) Utilize the powder that cold spray technology spr...

Embodiment 2

[0041] In the present embodiment, the base material selection thickness is 316 stainless steel with a thickness of 2mm, and the specific preparation method of the wear-resistant super-hydrophobic coating and the product is as follows:

[0042] (1) Clean the substrate with acetone, alcohol, and deionized water in sequence, and use 60-mesh brown corundum sand to roughen the surface of the substrate. The air pressure used for sandblasting is 0.5MPa, and the blasting time is 30s;

[0043] (2) The powder that adopts is the aluminum oxide powder of low surface energy material modification, and the concrete preparation method of the aluminum oxide powder of low surface energy material modification is: join aluminum oxide (diameter is 50 microns) in ethanol and make mass percentage concentration be 5%, and then add 5% heptadecafluorodecyltriethoxysilane to the solution and stir evenly.

[0044] (3) Use cold spray technology to spray powder, and the process parameters to control sprayi...

Embodiment 3

[0048] Embodiment 3 (comparative example)

[0049] In the present embodiment, the base material selection thickness is 316 stainless steel with a thickness of 2mm, and the specific preparation method of the wear-resistant super-hydrophobic coating and the product is as follows:

[0050] (1) Clean the substrate with acetone, alcohol, and deionized water in sequence, and use 60-mesh brown corundum sand to roughen the surface of the substrate. The air pressure used for sandblasting is 0.5MPa, and the blasting time is 30s;

[0051] (2) The powder that adopts is the aluminum oxide powder of low surface energy material modification, and the concrete preparation method of the aluminum oxide powder of low surface energy material modification is: join aluminum oxide (diameter is 50 microns) in ethanol and make mass percentage concentration be 5%, and then add 5% heptadecafluorodecyltriethoxysilane to the solution and stir evenly.

[0052] (3) Use cold spray technology to spray powder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com