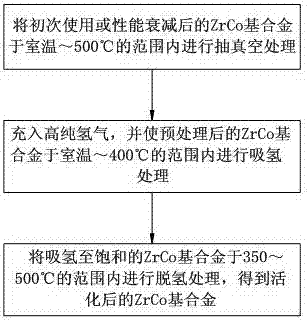

A method for rapidly and efficiently activating ZrCO-based hydrogen isotope storage materials

A hydrogen isotope, high-efficiency technology, applied in the field of rapid and efficient activation of ZrCo-based hydrogen isotope storage materials, can solve the problems of long activation time, complicated process, and inconspicuous activation effect, so as to ensure the activation effect, simplify the activation process, and shorten the activation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] In a glove box filled with argon, weigh the ZrCo-based alloy that was used for the first time or after performance degradation, and then put it into the reactor, and then use a vacuum pump to vacuum the reactor. This operation can make the ZrCo-based alloy In the protective atmosphere of inert gas (argon), it prevents oxidation in contact with air and affects its hydrogen absorption performance. While the reactor was evacuated, it was also heated up to 300°C at a heating rate of 5°C / min. After the temperature of the reaction kettle reached 300° C., vacuum was continued for 60 minutes, and then the reaction kettle was cooled to room temperature along with the furnace, and the reaction kettle was evacuated while cooling down. By heating, cooling and vacuuming the reactor, the ZrCo-based alloy can be prepared for hydrogen absorption.

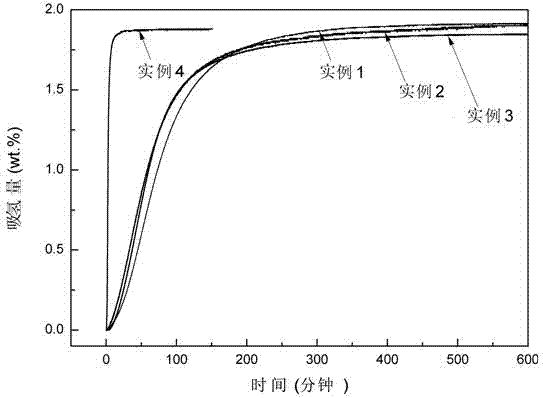

[0037] Then, fill the reactor with 80kPa high-purity hydrogen to absorb hydrogen. The hydrogen absorption curve is as follows figure 2 Shown...

example 2

[0039] As in Example 1, in a glove box filled with argon, weigh the ZrCo-based alloy that was used for the first time or after performance degradation, and then put it into the reactor. Then the reactor was evacuated and heated at 10°C. A heating rate of / min raises the temperature of the reactor to 500°C. After the temperature of the reaction kettle reached 500° C., vacuum was continued for 30 minutes, and then the reaction kettle was cooled to room temperature along with the furnace, and the reaction kettle was evacuated while cooling down.

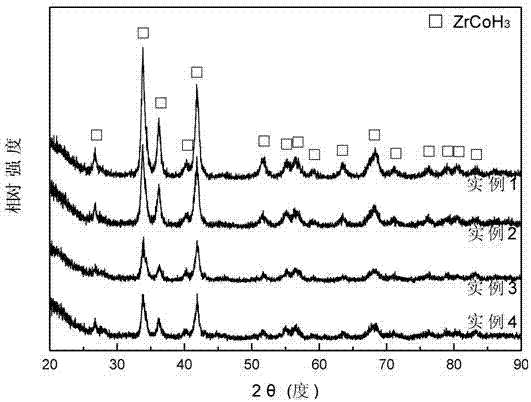

[0040] Fill the reactor with 80kPa high-purity hydrogen to absorb hydrogen. The hydrogen absorption curve is as follows figure 2 Shown. After the ZrCo-based alloy is saturated with hydrogen absorption (hydrogenation products such as image 3 As shown), vacuum the reactor again, and at the same time raise the temperature of the reactor to 500°C at a heating rate of 10°C / min. After the temperature of the reactor reaches 500°C, continue to ...

example 3

[0043] As in Example 1, in a glove box filled with argon, weigh the ZrCo-based alloy that was used for the first time or after performance degradation, and then put it into the reactor, and then evacuate the reactor at 8°C / The heating rate of min raises the temperature of the reactor to 500°C. After the temperature of the reaction kettle reached 500°C, vacuum was continued for 50 minutes, and then the reaction kettle was cooled to room temperature along with the furnace, and the reaction kettle was evacuated while cooling down.

[0044] Fill the reactor with 1 bar of high-purity hydrogen to absorb hydrogen. The hydrogen absorption curve is as follows figure 2 Shown. After the ZrCo-based alloy is saturated with hydrogen absorption (hydrogenation products such as image 3 Shown), vacuum the reactor again, and at the same time raise the temperature of the reactor to 400℃ at a heating rate of 5℃ / min. After the temperature of the reactor reaches 400°C, continue to vacuum for 60 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com