Responsiveness-based copolymer modified polypropylene (PP) micro-filtration membrane

A polypropylene microfiltration membrane and copolymer modification technology, applied in the field of functional polymer materials, can solve the problems of complex operation steps and processes, less intelligent modification of PP microfiltration membrane, etc., and achieve simplicity, convenience and repeatability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

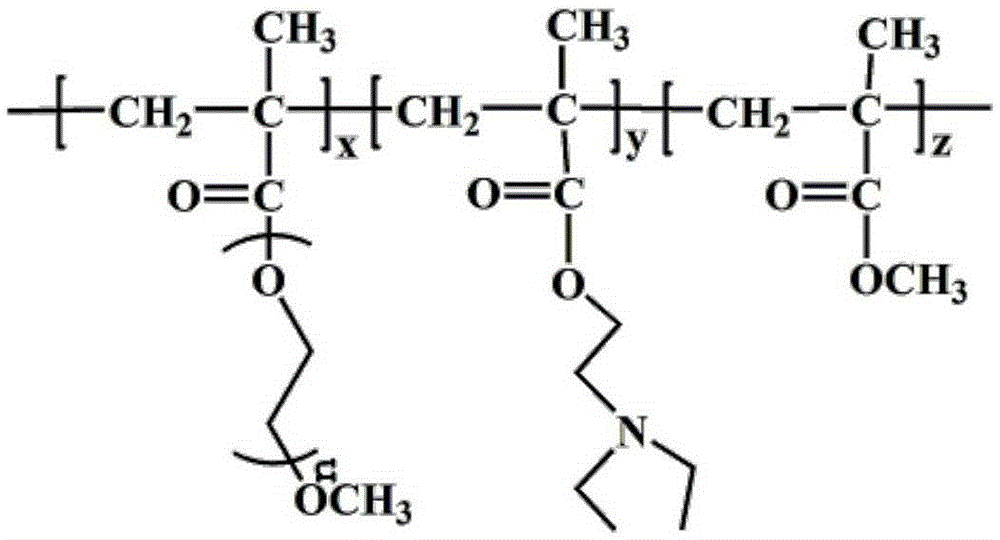

[0013] Embodiment 1, the synthesis of responsive ternary random copolymer PEDM

[0014] Add quantitative DEAEMA, MMA and calculated amount of PEGMA to a 50 mL round bottom flask, add 25 mL of 1,4-Dioxane and 1.5% of the total amount of monomer AIBN, pass N 2 After 30 minutes, it was sealed and reacted with stirring at 65°C for 12 hours to obtain the terpolymer P(PEGMA-co-DEAEMA-co-MMA). Using anhydrous ether as a precipitating agent, after three times of dissolution and precipitation, the unreacted monomers were removed, and then vacuum-dried to constant weight.

[0015] The resulting copolymer is:

[0016]

[0017] n=5-6, x=6-15; y=9-30; z=40-70, expressed as PEDM.

Embodiment 2

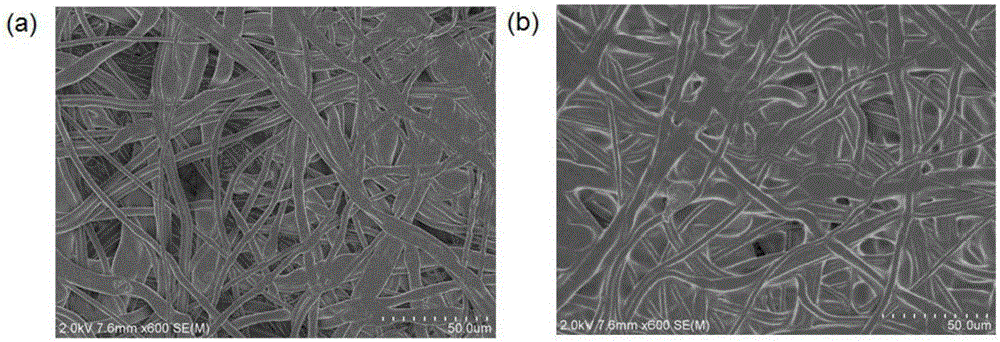

[0018] Embodiment 2, preparation of responsive polypropylene microfiltration membrane

[0019] Dissolve the responsive copolymer in a solvent and prepare a surface modifier solution with a certain concentration. Soak the PP microfiltration membrane in the solution containing the surface modifier at room temperature for 20 hours, then take it out, and rinse the soaked sample with distilled water for 2 hours , and then soak the sample in water at 20°C for 20min, and finally dry it in vacuum. Change the specific process conditions, such as the concentration of the modifier, the treatment temperature, etc., and use the same method to modify the polypropylene microfiltration membrane.

Embodiment 3

[0020] Embodiment 3, the preparation of responsive polypropylene microfiltration membrane

[0021] Dissolve the responsive copolymer in different solvents, prepare a surface modifier solution with a certain concentration, soak the PP microfiltration membrane in the solution containing the surface modifier for 20 hours, take it out, rinse the soaked sample with distilled water for 2 hours, and then Soak the sample in water at 20°C for 20 min, and finally dry it in vacuum. Change the specific process conditions, such as the concentration of the modifier, the treatment temperature, etc., and use the same method to modify the polypropylene microfiltration membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com