A kind of H acid production industrial wastewater treatment method

A technology for industrial wastewater and treatment methods, applied in water/sewage treatment, aerobic process treatment, natural water treatment, etc., can solve the problems of high fuel quality and combustion operating conditions, consumption of large oxidants, and immature technology. To achieve the effect of reasonable process design, high distribution coefficient, comprehensive management and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

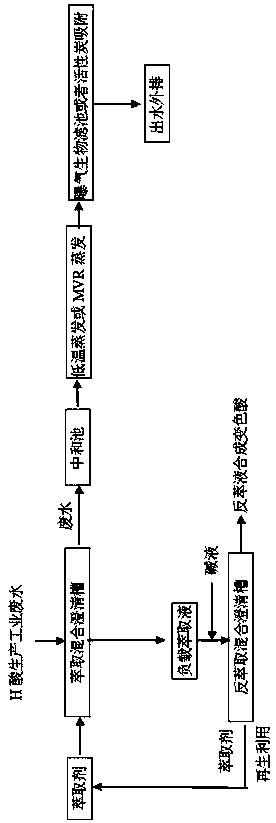

[0019] Embodiment 1, with reference to figure 1 , a kind of H acid production industrial wastewater treatment method, its steps are as follows:

[0020] (1) Extraction: Under normal pressure, H acid waste water is fully mixed with the extractant at 40°C for 2 minutes at a volume ratio of oil to water phase of 4:1. The raffinate phase after stratification is the extraction. The extractant is sent to the re-extraction section for regeneration; the extraction stage is one level;

[0021] (2) Back-extraction: take the above-mentioned extraction phase and mix it with lye at 40°C under normal pressure, add alkali to the back-extraction to control the pH end value at 8, and prepare the color-changing acid from the back-extraction after layering, and extract after regeneration Recycling agent is used for extraction, and the back extraction stage is one level; the lye is a NaOH solution with a mass concentration of 5%;

[0022] (3) Evaporation: extract the water and neutralize it to ...

Embodiment 2

[0024] Embodiment 2, with reference to figure 1 , a kind of H acid production industrial wastewater treatment method, its steps are as follows:

[0025] (1) Extraction: Under normal pressure, the H acid waste water is fully mixed with the extractant at 100°C for 10 minutes according to the volume ratio of the oil-water phase at 1:8. The raffinate phase after stratification is the extraction. The extractant is sent to the re-extraction section for regeneration; the extraction stage is one level;

[0026] (2) Stripping: Take the above extraction phase and mix it with lye at 100°C under normal pressure, add alkali in the stripping to control the pH end value at 11, and prepare the color-changing acid from the stripping solution after layering, and extract after regeneration Recycling agent is used for extraction, and the back extraction stage is one level; the lye is a KOH solution with a mass concentration of 30%;

[0027] (3) Evaporation: extract the water and neutralize it t...

Embodiment 3

[0029] Embodiment 3, with reference to figure 1 , a kind of H acid production industrial wastewater treatment method, its steps are as follows:

[0030] (1) Extraction: Under normal pressure, the H acid waste water is fully mixed with the extractant at 60°C for 5 minutes according to the volume ratio of the oil-water phase at 1:1. The raffinate phase after stratification is the extraction. The extractant is sent to the re-extraction section for regeneration; the extraction stage is one level;

[0031] (2) Stripping: Take the above extraction phase and mix it with lye at 60°C under normal pressure, add alkali in the stripping to control the pH end value at 9, and prepare the color-changing acid from the stripping solution after layering, and extract after regeneration Recycling agent is used for extraction, and the back extraction stage is one level; the lye is NaOH, KOH, sodium carbonate or sodium bicarbonate solution with a mass concentration of 20%;

[0032] (3) Evaporatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com