Stainless steel welding wire and preparation method thereof

A technology of stainless steel and stainless steel strips, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of high strength and fatigue resistance, achieve good welding performance, high welding efficiency, and improve high-temperature durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

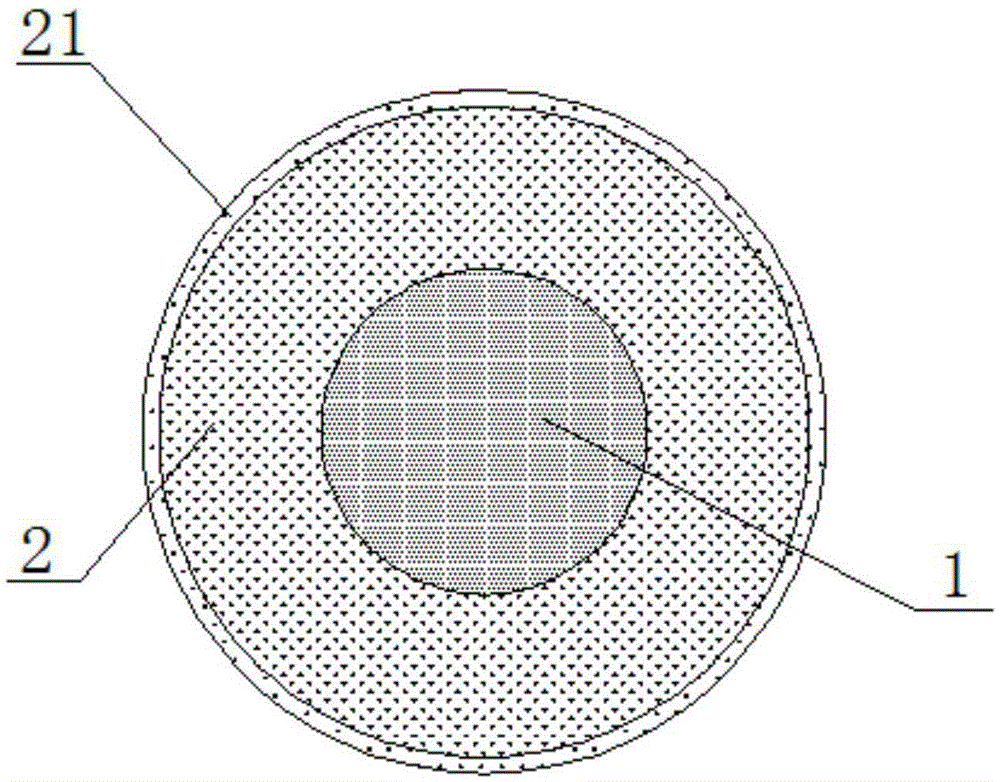

[0041] figure 1 A schematic structural view of the stainless steel welding wire and its preparation method provided by the embodiments of the present invention; figure 1 As shown, the stainless steel welding wire provided in this embodiment is composed of a flux core 1 and a stainless steel strip 2 wrapping the flux core 1, and the flux core 1 accounts for 35% of the total weight of the stainless steel welding wire;

[0042] Drug core 1 comprises the following weight ratio components:

[0043] Ti48%~50%, Si10%~13%, Mn10%~12%, KBF 4 10%-12%, Nb5%-7%, Mo5%-6%, Mg3%-4%, N1%-2%, and the rest is Fe.

[0044] In the alternative of the present embodiment, the stainless steel band 2 comprises the following weight ratio components:

[0045] Cr23%~25%, Ni19%~20%, Cu6%~8%, Mg5%~6%, Mo1%~2%, Si0.4%~0.8%, C0.3%~0.5%, Nb0.3% ~0.5%, N0.3%~0.4%, S0.005%~0.01%, P0.005%~0.01%, and the rest is Fe.

[0046] In an alternative solution of this embodiment, the drug core 1 is filled in the stain...

Embodiment 2

[0063] The stainless steel welding wire provided in this embodiment is composed of a flux core 1 and a stainless steel strip 2 wrapping the flux core 1, and the flux core 1 accounts for 30% of the total weight of the stainless steel welding wire;

[0064] Drug core 1 comprises the following weight ratio components:

[0065] Ti45%~48%, SiO 2 13%~15%, Mn12%~14%, KBF 4 12%-13%, Nb5%-8%, Mo5%-7%, MgO4%-5%, N1%-2%, and the rest is Al.

[0066] In the alternative of the present embodiment, the stainless steel band 2 comprises the following weight ratio components:

[0067] Cr22%~23%, Ni18%~19%, Cu5%~6%, Mg5%~6%, Mo2%~3%, Si0.5%~0.8%, C0.3%~0.5%, Nb0.3% ~0.5%, N0.3%~0.4%, S0.005%~0.01%, P0.005%~0.01%, and the rest is Fe.

[0068] In the alternative of this embodiment, the preparation method of drug core 1 includes the following steps:

[0069] Vacuum furnace smelting, forging, drawing, solution heat treatment, continuous drawing, mechanical cleaning;

[0070] During the smeltin...

Embodiment 3

[0081] The stainless steel welding wire provided in this embodiment is composed of a flux core 1 and a stainless steel strip 2 wrapping the flux core 1, and the flux core 1 accounts for 25% of the total weight of the stainless steel welding wire;

[0082] Drug core 1 comprises the following weight ratio components:

[0083] Ti40%~45%, Si13%~15%, Mn13%~14%, KBF 4 12% to 13%, Nb7% to 8%, Mo6% to 7%, Mg4% to 5%, N1% to 2%, and the rest is Al.

[0084] In the alternative of the present embodiment, the stainless steel band 2 comprises the following weight ratio components:

[0085] Cr20%~22%, Ni18%~29%, Cu4%~5%, Mg4%~5%, Mo2%~3%, Si0.4%~0.8%, C0.3%~0.5%, Nb0.3% ~0.5%, N0.3%~0.4%, S0.005%~0.01%, P0.005%~0.01%, and the rest is Fe.

[0086] In the alternative of this embodiment, the preparation method of drug core 1 includes the following steps:

[0087] Vacuum furnace smelting, forging, drawing, solution heat treatment, continuous drawing, mechanical cleaning;

[0088] During th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com