The Method of Controlling Center Line Cracks in Steel Plate Continuous Casting Process

A continuous casting process and control center technology, applied in the field of metallurgical processes, can solve the problems of not eliminating centerline cracks, not pointing out continuous casting and rolling production, and inability to reduce other cracks, etc. Even cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

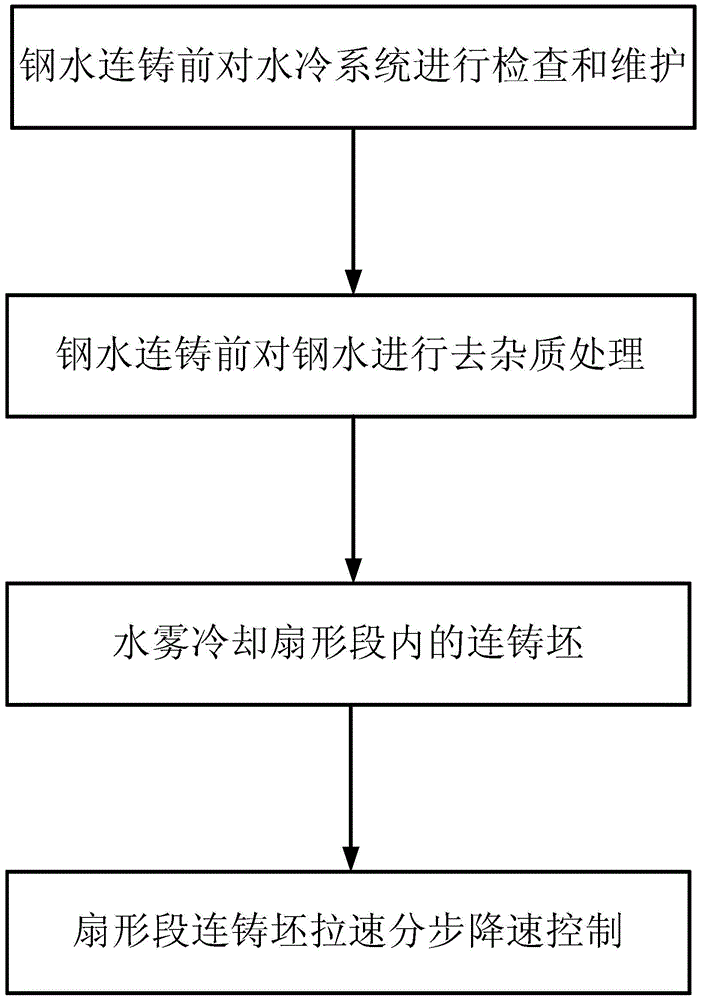

Method used

Image

Examples

Embodiment 1

[0046] The raw material of molten steel used in this embodiment is a set of 10 furnaces of Q235B plain carbon molten steel. The size of the cast billet produced is 1500mm*230mm*long. The molten steel is treated with impurities before the molten steel is cast before the molten steel enters the converter. Carry out desulfurization treatment to ensure that the S content of the molten iron entering the converter is 0.018wt%, and the slag is fully removed; the top and bottom composite blowing smelting of the molten iron is used in the converter to ensure that the P content of the molten steel is 0.018wt% and the C content is 0.08wt% .

[0047] Before continuous casting of molten steel, check the atomization nozzles in the sector section for inspection. It is found that the atomization nozzles in the foot roller section and the zero section are not clogged, the arc section is blocked by 2, the horizontal section is blocked by 4, and the water supply There is no leakage in the pipeline....

Embodiment 2

[0052] The raw material of molten steel used in this embodiment is a set of 12 furnaces of Stb32 low-carbon aluminum killed steel, and the size of the produced cast slab is 1820mm*230mm*long; the molten steel is treated for impurity removal before the molten steel is cast, and the molten iron enters the converter Prior to desulfurization treatment, ensure that the S content of molten iron entering the converter is 0.008wt%, and fully slag off; in the converter, the molten iron is smelted by top-bottom combined blowing to ensure that the molten steel has a P content of 0.008wt% and a C content of 0.05wt %.

[0053] Before continuous casting of molten steel, check the atomization nozzles in the sector section. It is found that there is no blockage of the atomization nozzles in the foot roller section and the zero section, the number of blocked atomization nozzles in the arc section is 1, the number of blocked atomization nozzles in the horizontal section is 3, and the water supply ...

Embodiment 3

[0058] The raw material of molten steel used in this embodiment is a set of 12 furnaces of Stb32 low-carbon aluminum killed steel, and the size of the cast slab produced is 1820mm*230mm*long; the molten steel is treated for impurity removal before the molten steel is cast before the molten steel enters the converter. Desulfurization treatment is carried out before, to ensure that the S content of the molten iron entering the converter is 0.012wt%, and the slag is fully removed; the top and bottom composite blowing smelting of the molten iron is used in the converter to ensure that the P content of the molten steel is 0.012wt% and the C content is 0.06wt %.

[0059] Before continuous casting of molten steel, check the atomization nozzles in the sector section for inspection. It is found that the atomization nozzles in the foot roller section and the zero section are not clogged, the number of blocked atomization nozzles in the arc section is 0, the number of blocked atomization noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com