Cyclone plate dedusting and demisting device and method capable of preventing secondary carrying

A technology of demisting device and swirl plate, which is applied in combination devices, separation methods, chemical instruments and methods, etc., can solve the problems of low dust removal efficiency, poor film formation, scaling and clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

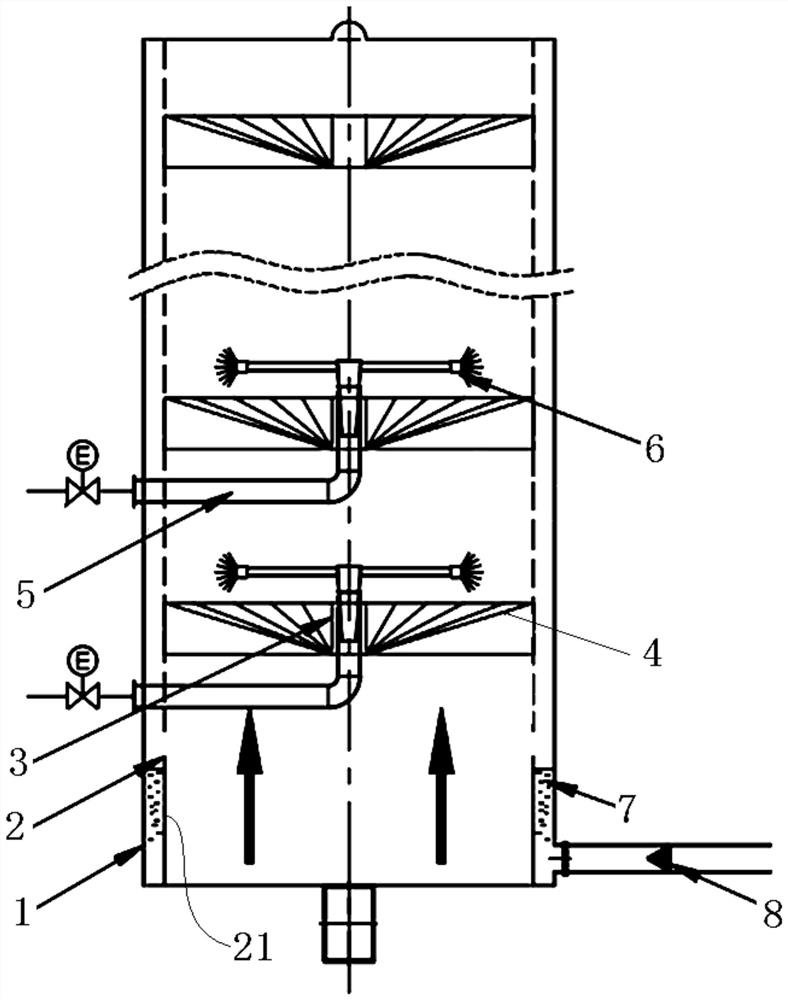

[0043] Such as figure 1 shown. The invention discloses a swirl plate dust and mist removal device for preventing secondary carryover, which comprises an outer cylinder 1, a screen cylinder 2 and a central cylinder 3 which are sequentially sleeved from the outside to the inside;

[0044] A smoke dead zone where the smoke cannot flow is formed between the screen cylinder 2 and the outer cylinder 1, which isolates the flowing smoke from the liquid film on the inner wall of the outer cylinder 1, fundamentally solving the problem of secondary entrainment.

[0045] The middle and lower peripheral wall of the screen cylinder 2 is a non-porous section 21, and the middle and upper peripheral wall is a sieve hole section;

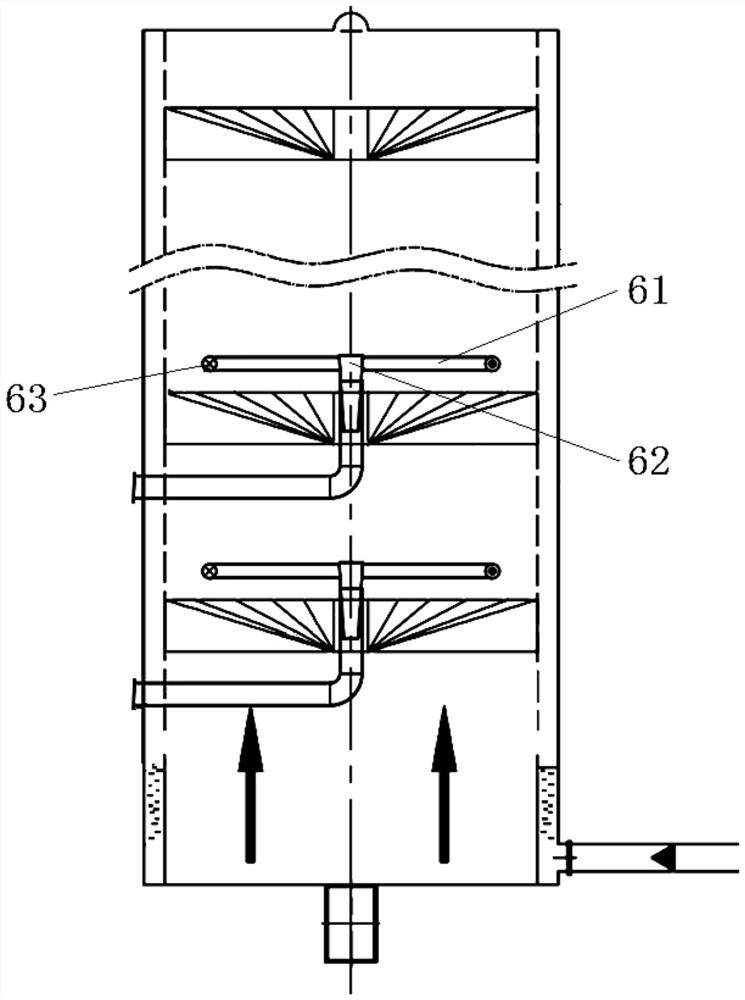

[0046] In the sieve section, multi-stage swirl plates 4 are arranged at intervals from top to bottom; except for the last stage of swirl plates 4, flushing nozzle mechanisms are arranged above the remaining stages of swirl plates 4; the flushing nozzle mechanisms pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com