Spiral groove demisting and dedusting device and method capable of preventing secondary carrying

A technology of dust removal device and spiral groove, which is applied in the direction of separation method, combined device, chemical instrument and method, etc., can solve the problems of low dust removal efficiency, fouling blockage, poor film formation, etc., and achieve high dust removal efficiency, small resistance, and prevent The effect of smoke escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

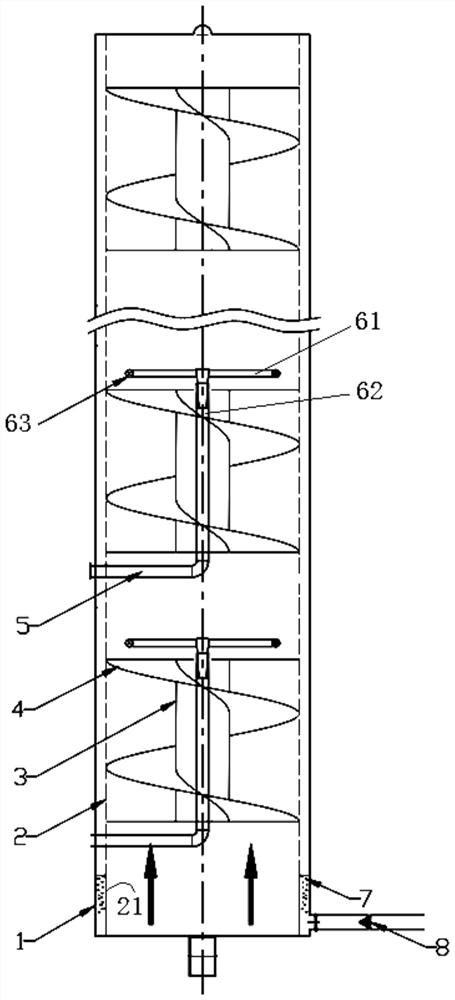

[0043] Such as figure 1 shown. The invention discloses a spiral groove anti-fog and dust removal device for preventing secondary carryover, which is characterized in that it includes an outer cylinder 1, a screen cylinder 2 and a central cylinder 3 which are sequentially sleeved from outside to inside;

[0044] The lower peripheral wall of the screen cylinder 2 is a non-porous section 21, and the upper peripheral wall is a sieve section;

[0045] In the sieve section, there are multi-stage strip-shaped spiral plates 4 arranged at intervals from top to bottom; except for the last stage of strip-shaped spiral plates 4, flushing nozzle mechanisms are arranged above the remaining levels of strip-shaped spiral plates 4; The nozzle mechanism is connected with the external water source through the flushing water pipe 5;

[0046] The water for flushing the nozzle mechanism wets the helical blade of the strip-shaped spiral plate 4, and forms a liquid film on the surface of the helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com