Wave plate spiral groove dedusting and demisting device

A demisting device and spiral groove technology, applied in the field of flue gas purification and treatment, can solve the problems of low efficiency of secondary dust removal and achieve the effects of preventing flue gas from escaping, high dust removal efficiency, and strong water collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

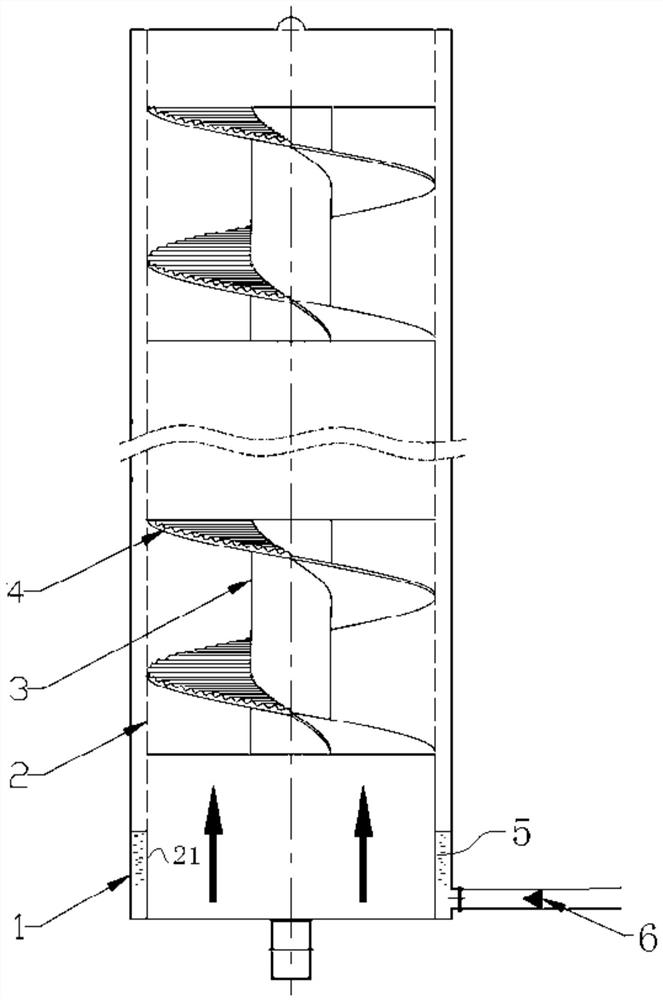

[0033] Such as figure 1 shown. The invention discloses a corrugated plate spiral groove dedusting and demisting device, which comprises an outer cylinder 1, a screen cylinder 2 and a central cylinder 3 which are sequentially sleeved from outside to inside;

[0034] The lower peripheral wall of the screen cylinder 2 is a non-porous section 21, and the upper peripheral wall is a sieve section;

[0035] In the sieve section, there are multi-stage belt-shaped corrugated spiral plates 4 arranged at intervals from top to bottom;

[0036] The strip-shaped wave spiral plate 4 spirals and wraps around the central cylinder 3, forming a spiral channel in the screen cylinder 2;

[0037] The space between the screen cylinder 2 and the outer cylinder 1 constitutes a smoke dead zone; the screen cylinder 2 can completely separate the smoke flow area from the liquid film adsorption area on the inner wall of the outer cylinder 1, solving the problem of Second carry problem.

[0038] The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com