Three-dimensional shape measurement method

A measurement method and technology of three-dimensional shape, which can be applied to measurement devices, instruments, optical devices, etc., can solve problems such as writing gratings, and achieve the effect of reducing implementation costs and simplifying manufacturing processes and processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

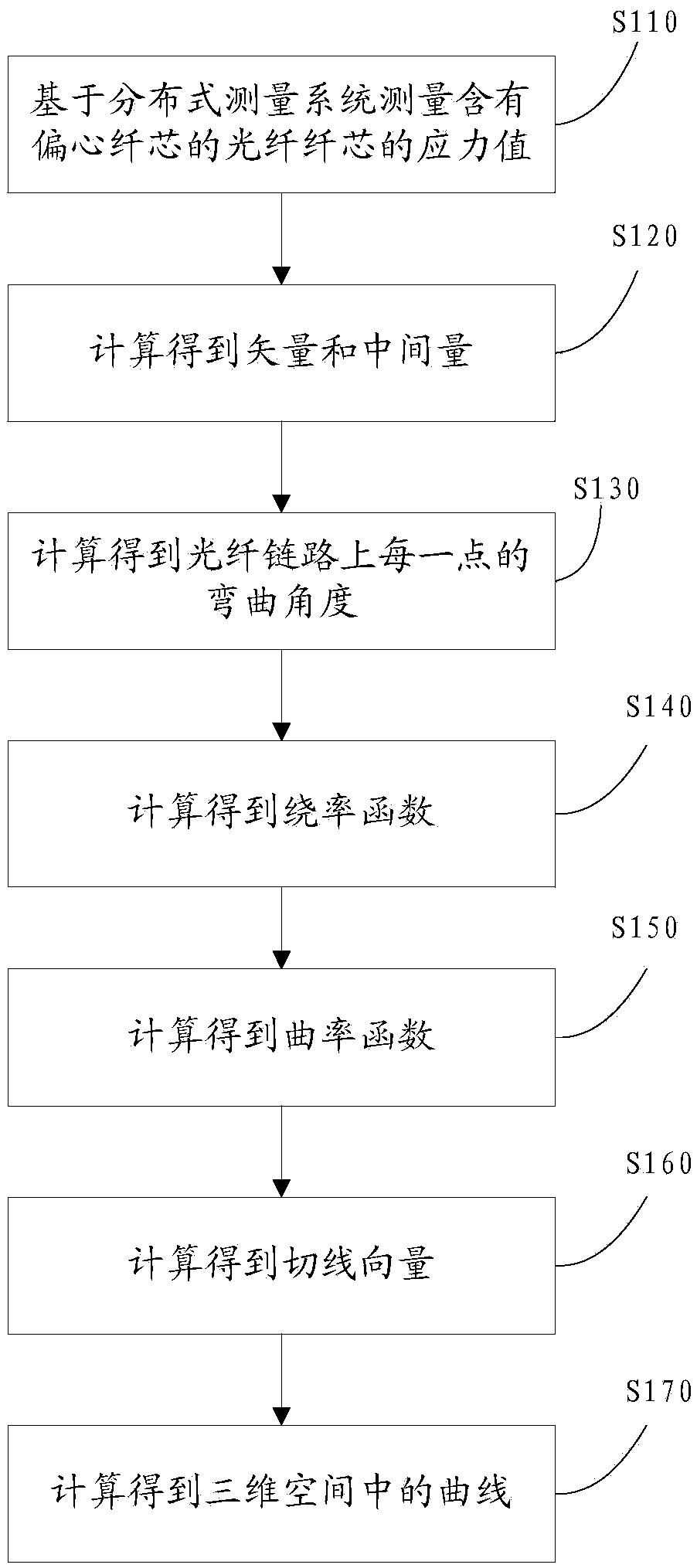

[0046] see figure 2 , the three-dimensional shape measurement method provided by the embodiment of the present invention, comprising:

[0047] Step S110: Measure the stress value ε of the fiber core i containing the eccentric core based on the distributed measurement system i ;

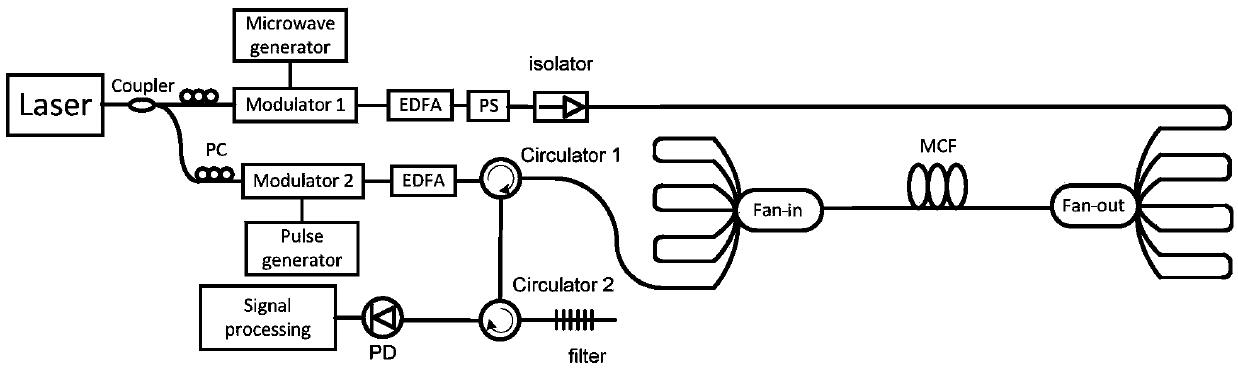

[0048] In this embodiment, the distributed measurement system includes but is not limited to BOTDR (Brillouinopticaltime-domainreflectometry, Brillouin optical time domain reflectometry), BOTDA (Brillouinopticaltime-domainanalysis, Brillouinoptical time domain analyzer), BOCDR (Brillouinopticalcorrelationdomainreflectometry, Brillouin correlation domain reflectometer), BOCDA (Brillouinopticalcorrelationdomainanalysis, Brillouin correlation domain analyzer), BOFDA (Brillouinopticalfrequencydomainanalysis, Brillouin optical frequency domain analyzer), OFDR (Opticalfrequencydomain reflectometry, optical frequency domain reflectometry), C-OTDR (Coherentoptical time-domain reflectometer, coherent optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com