Silicone sealant with ultra-high strength and preparation method of silicone sealant

A silicone sealant, ultra-high-strength technology, used in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of limited application, high system viscosity, low mechanical properties, etc. The effect of improving low strength, improving mechanical strength, and large tensile bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

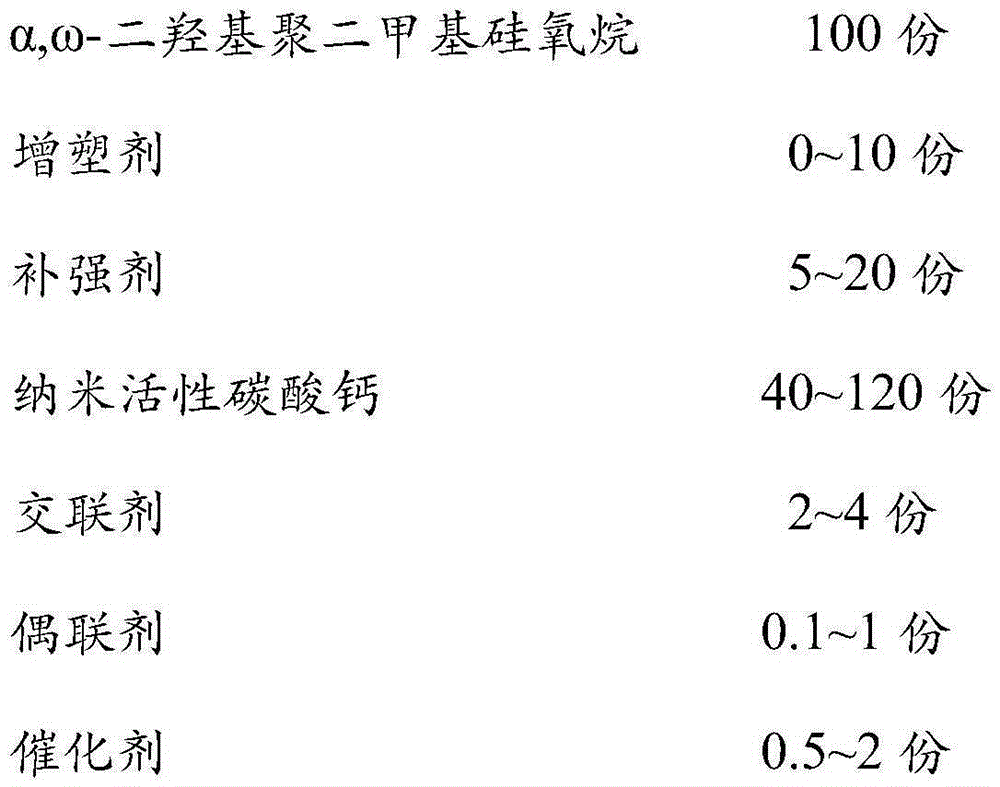

[0026] The ultra-high-strength silicone sealant of this embodiment is prepared from the following raw materials in parts by weight:

[0027]

[0028] The preparation method of the ultra-high strength silicone sealant of the present embodiment comprises the following steps:

[0029] (1) Reinforcement agent pre-dispersion: Add 20 parts of DMC (dimethylcyclosiloxane mixture) to 5 parts of carbon nanotubes (reinforcing agent) and mix, place in an ultrasonic disperser for ultrasonic dispersion for 30 minutes, Make reinforcing agent dispersion;

[0030] (2) Base material preparation: 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 20000Pa.s, 5 parts of methyl silicone oil (plasticizer) with a viscosity of 500Pa.s, Strong agent dispersion, 80 parts of active nano-calcium carbonate were stirred in a kneader for 3 hours, the temperature of the kneader was 150°C, vacuumized, and the discharge was cooled to obtain the base material;

[0031] (3) Add 3 parts of met...

Embodiment 2

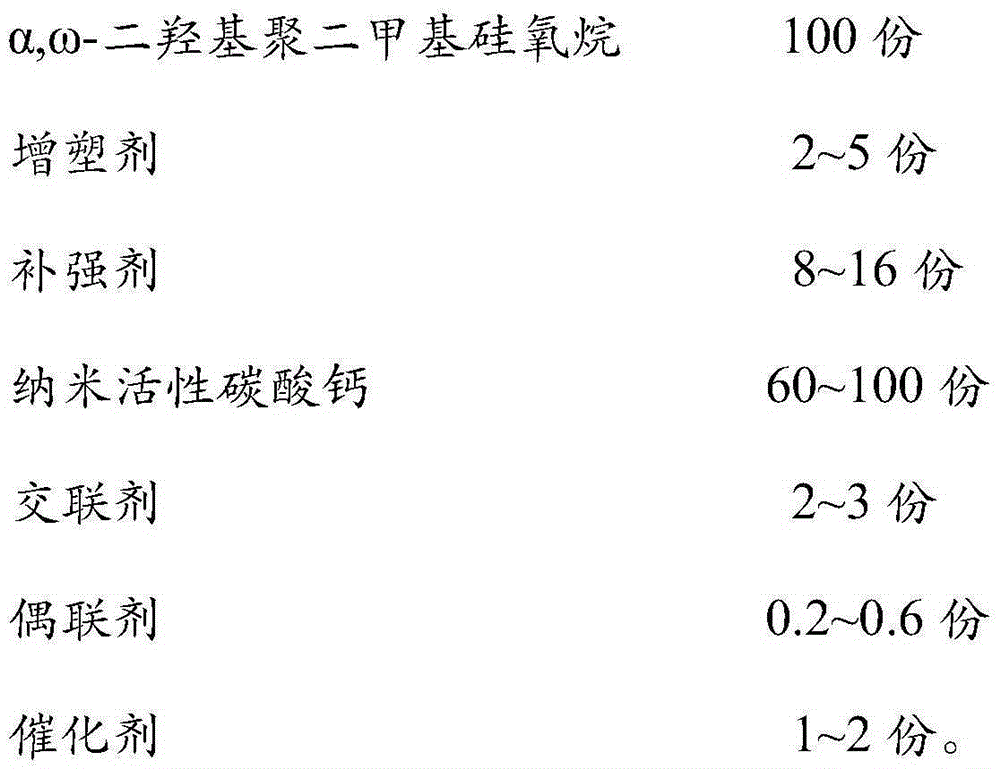

[0033] The ultra-high-strength silicone sealant of this embodiment is prepared from the following raw materials in parts by weight:

[0034]

[0035] The preparation method of the ultra-high strength silicone sealant of the present embodiment comprises the following steps:

[0036] (1) Reinforcement agent pre-dispersion: Add 20 parts of DMC (dimethylcyclosiloxane mixture) to 5 parts of carbon nanotubes (reinforcing agent) and mix, place in an ultrasonic disperser for ultrasonic dispersion for 30 minutes, Make reinforcing agent dispersion;

[0037] (2) Base material preparation: 100 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 50000Pa.s, 5 parts of MDT methyl silicone oil with a viscosity of 500Pa.s, and a reinforcing agent dispersion 1. 60 parts of active nano-calcium carbonate were stirred in a kneader for 2 hours, the temperature of the kneader was 150° C., vacuumized, and the discharge was cooled to obtain the base material;

[0038] (3) Add 2 parts ...

Embodiment 3

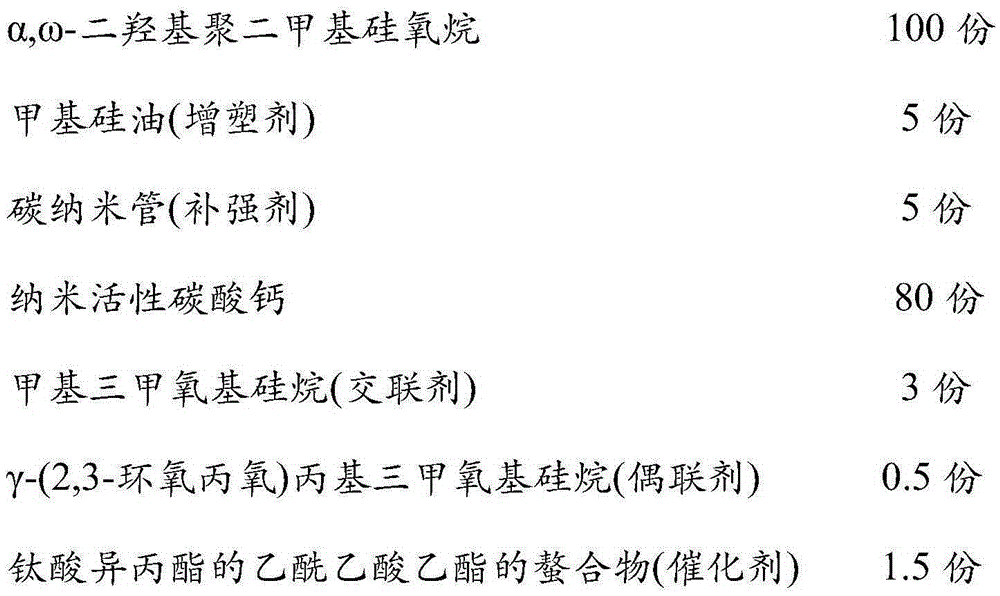

[0040] The ultra-high-strength silicone sealant of this embodiment is prepared from the following raw materials in parts by weight:

[0041]

[0042] The preparation method of the ultra-high strength silicone sealant of the present embodiment comprises the following steps:

[0043] (1) Reinforcing agent pre-dispersion: Add 40 parts of DMC (dimethylcyclosiloxane mixture) to 10 parts of carbon nanotubes (reinforcing agent) and mix, place in an ultrasonic disperser for ultrasonic dispersion for 30 minutes, Make reinforcing agent dispersion;

[0044] (2) Base material preparation: 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 50000Pa.s, 5 parts of methyl silicone oil (plasticizer) with a viscosity of 500Pa.s, Strong agent dispersion, 60 parts of active nano-calcium carbonate were stirred in a kneader for 2 hours, the temperature of the kneader was 150°C, vacuumized, and the discharge was cooled to obtain the base material;

[0045] (3) Add 3 parts of meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com