Separation method and system for byproduct 2M2BN in course of producing 3PN by 2M3BN isomerization

A separation method and isomerization technology, which is applied in the purification/separation of carboxylic acid nitriles, organic chemistry, etc., can solve the problems of 2M3BN and 2M2BN separation methods, reaction conversion rate and selectivity reduction that are not mentioned, and reduce equipment costs and the effect of operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

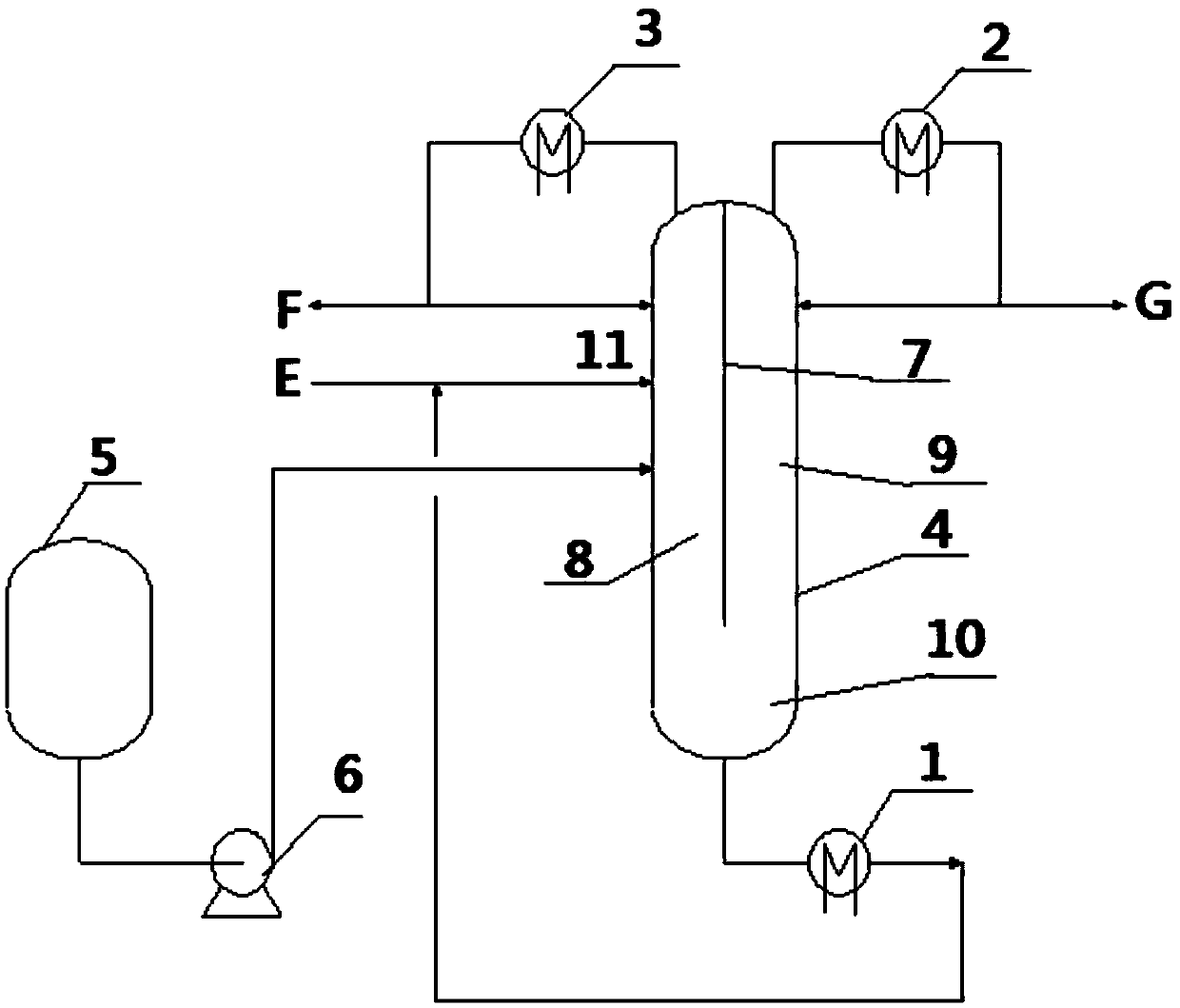

[0028] A separation system for by-product 2M2BN in the process of 2M3BN isomerization to produce 3PN, comprising a tower bottom reboiler 1, a tower top 2M3BN cooler 2, a tower top 2M2BN cooler 3, a rectification tower 4, a feed tank 5, and a The feed pump 6 and the feed tank 5 are connected to the rectification tower 4 through the feed pump 6, a bottom reboiler 1 is arranged at the bottom of the rectification tower 4, a partition 7 is arranged in the rectification tower 4, and the upper part inside the tower body is divided into The left area 8 and the right area 9, the lower part of the tower body is an unseparated public area 10, the tower top 2M2BN cooler 3 is installed on the top of the tower in the left area 8, and the tower top 2M3BN cooler 2 is installed on the top of the right area 9. An extraction agent feed port 11 is arranged at the top of the left area 8 of the distillation column 4 .

[0029] The rectification tower 4 has a diameter of 300 mm and a tower height of...

Embodiment 2

[0031]A separation system for by-product 2M2BN in the process of 2M3BN isomerization to produce 3PN, comprising a tower bottom reboiler 1, a tower top 2M3BN cooler 2, a tower top 2M2BN cooler 3, a rectification tower 4, a feed tank 5, and a The feed pump 6 and the feed tank 5 are connected to the rectification tower 4 through the feed pump 6, a bottom reboiler 1 is arranged at the bottom of the rectification tower 4, a partition 7 is arranged in the rectification tower 4, and the upper part inside the tower body is divided into The left area 8 and the right area 9, the lower part of the tower body is an unseparated public area 10, the tower top 2M2BN cooler 3 is installed on the top of the tower in the left area 8, and the tower top 2M3BN cooler 2 is installed on the top of the right area 9. An extraction agent feed port 11 is arranged at the top of the left area 8 of the distillation column 4 .

[0032] The rectification tower 4 has a diameter of 300mm and a tower height of 7...

Embodiment 3

[0034] A separation system for by-product 2M2BN in the process of 2M3BN isomerization to produce 3PN, comprising a tower bottom reboiler 1, a tower top 2M3BN cooler 2, a tower top 2M2BN cooler 3, a rectification tower 4, a feed tank 5, and a The feed pump 6 and the feed tank 5 are connected to the rectification tower 4 through the feed pump 6, a bottom reboiler 1 is arranged at the bottom of the rectification tower 4, a partition 7 is arranged in the rectification tower 4, and the upper part inside the tower body is divided into The left area 8 and the right area 9, the lower part of the tower body is an unseparated public area 10, the tower top 2M2BN cooler 3 is installed on the top of the tower in the left area 8, and the tower top 2M3BN cooler 2 is installed on the top of the right area 9. An extraction agent feed port 11 is arranged at the top of the left area 8 of the distillation column 4 .

[0035] The rectification tower 4 has a diameter of 300 mm and a tower height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com