Automatic packaging line for carbon fiber yarns

An automatic packaging and carbon fiber filament technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve the problems of easy damage, carbon fiber filament rollers are not wear-resistant, etc., achieve a high degree of automation, ensure data accuracy, and ensure product information The effect of traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

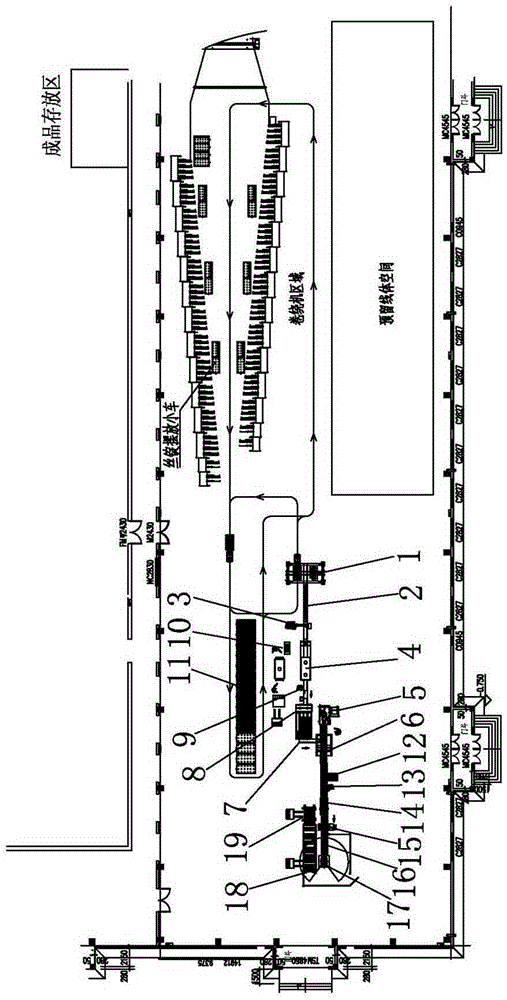

[0011] Such as figure 1 As shown, the automatic packaging line for carbon fiber filaments consists of a Cartesian robot 1, a feeding conveyor 2, a robot grabbing, weighing and scanning device 3, an automatic sealing and cutting shrinking device 4, an unpacking machine 5, a packing machine 6, and a chain plate Conveyor 7, automatic sorting machine 8, outer surface labeling 9, full material temporary storage area 10, non-standard product manual processing area 11, weighing and rejecting machine 12, labeling machine 13, folding and sealing machine 14, bundling The charter machine 15, the grabbing station machine 16, the palletizing robot 17, the palletizing station machine 18 and the empty pallet distributing machine 19 are composed, the automatic sorting machine 8 is connected with the box packing machine 6 through the chain conveyor 7, and the box unpacking machine 5. Cartoning machine 6, weighing and rejecting machine 12, labeling machine 13, folding and sealing machine 14, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com