Rubber mixing machine with self-cleaning function

A technology of rubber mixing machine and function, applied in the field of rubber mixing machine with self-cleaning function, can solve the problems of affecting the good rate of finished products, residue retention, affecting the use of the next process, etc., to increase the good rate, not easy to block, eat strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

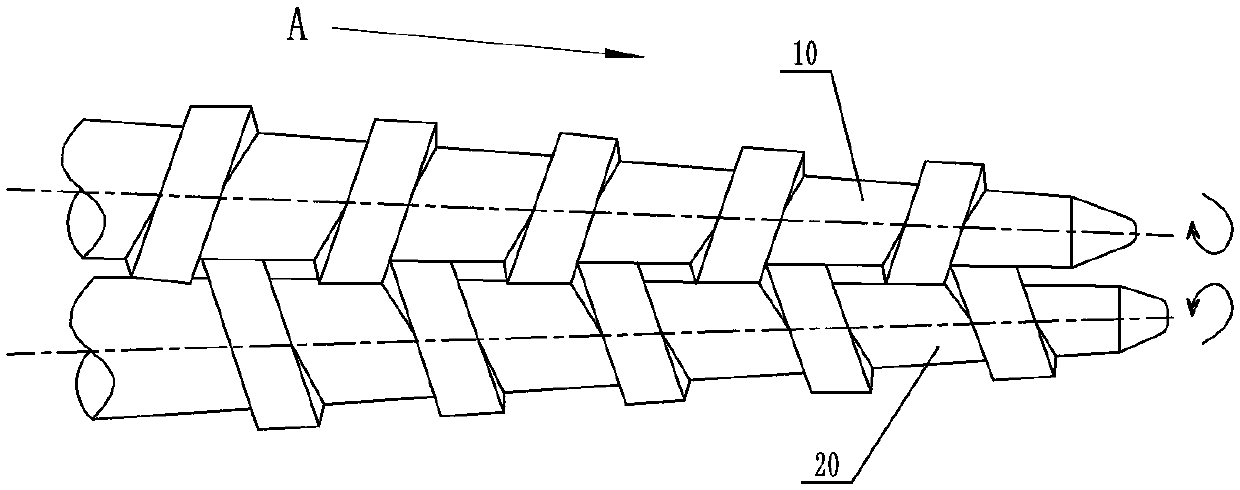

[0015] The reference signs in the drawings of the description include: the first screw 10, the second screw 20, and A refers to the length direction.

[0016] Such as figure 1 As shown, the rubber mixing machine with self-cleaning function includes a rubber mixing machine body, a first screw 10 and a second screw 20 that engage with each other. Both the first screw 10 and the second screw 20 are rotatably arranged on the rubber mixing machine body, and are respectively connected with the output shaft of the motor. The first screw 10 and the second screw 20 are tapered screws, the depths of the grooves of the first screw 10 and the second screw 20 gradually change along the direction A, and the depths of the grooves of the first screw 10 and the second screw 20 equal to its diameter.

[0017] In this scheme, the lengths of the first screw 10 and the second screw 20 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com