Manufacturing method of small prefabricated box girder

A manufacturing method and technology of small box girders, applied in the direction of manufacturing tools, molds, ceramic molding cores, etc., can solve the problems of low work efficiency and increased labor intensity of workers, and achieve reduced labor intensity, convenient demoulding and mold closing, The effect of advanced design, production and construction technology concepts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

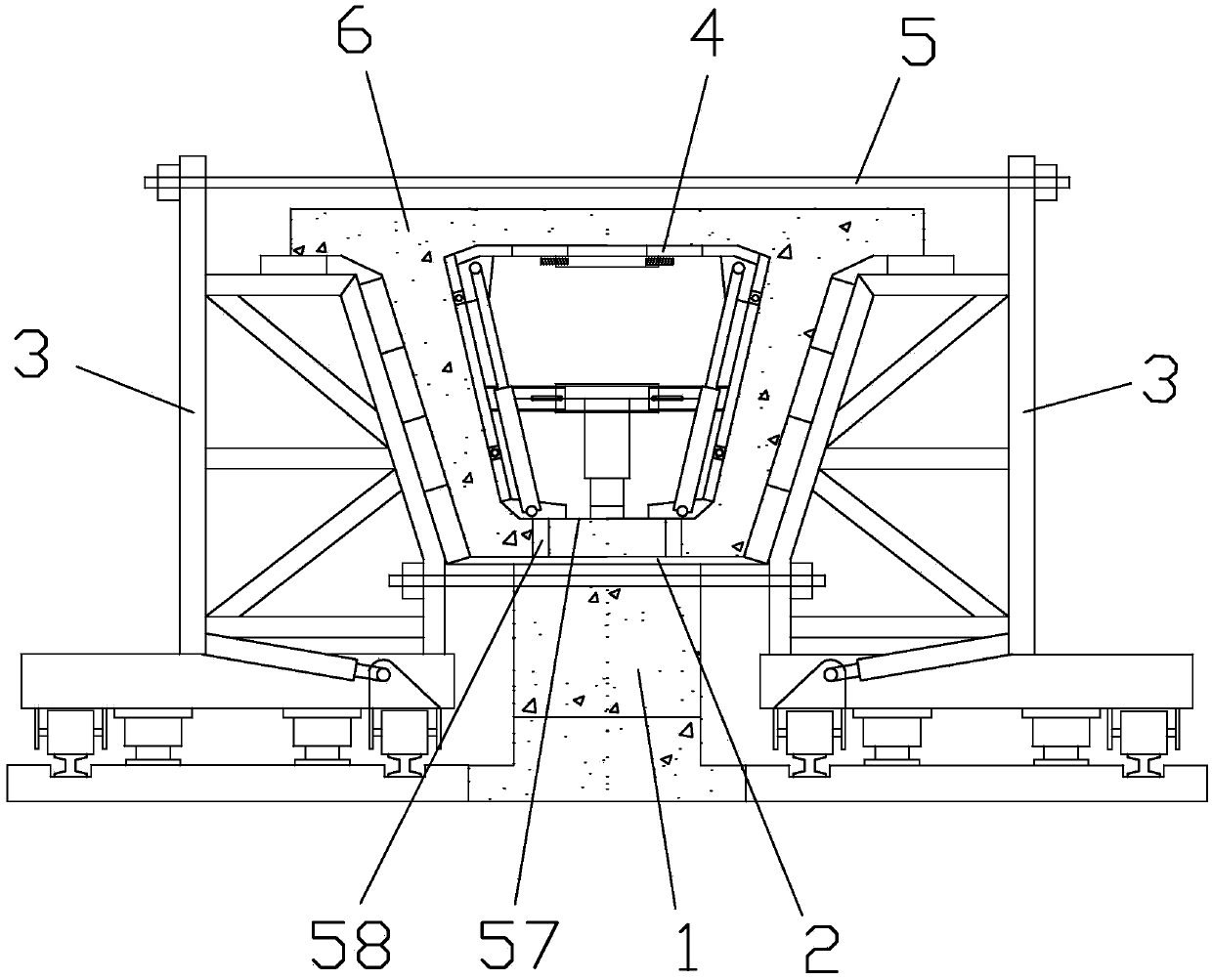

[0046] refer to Figure 1 to Figure 6 , a kind of manufacturing method of prefabricated small box girder provided by the present invention, comprises the following steps:

[0047] Step 1, prefabricated pedestal 1, pedestal 1 is the basic platform in the process of prefabricating the prestressed small box girder, supporting the entire weight of the unformed small box girder, and ensuring that the small box girder is in a horizontal position during the forming process, so that the small box girder After the beam is formed, it has uniform mechanical strength; it is required that the elevation difference of the foundation pedestal is not more than 15mm, the angle steel of each edge protection is firm, and the design requirements of the groove size on the pedestal at both ends meet the requirements and the position is accurate;

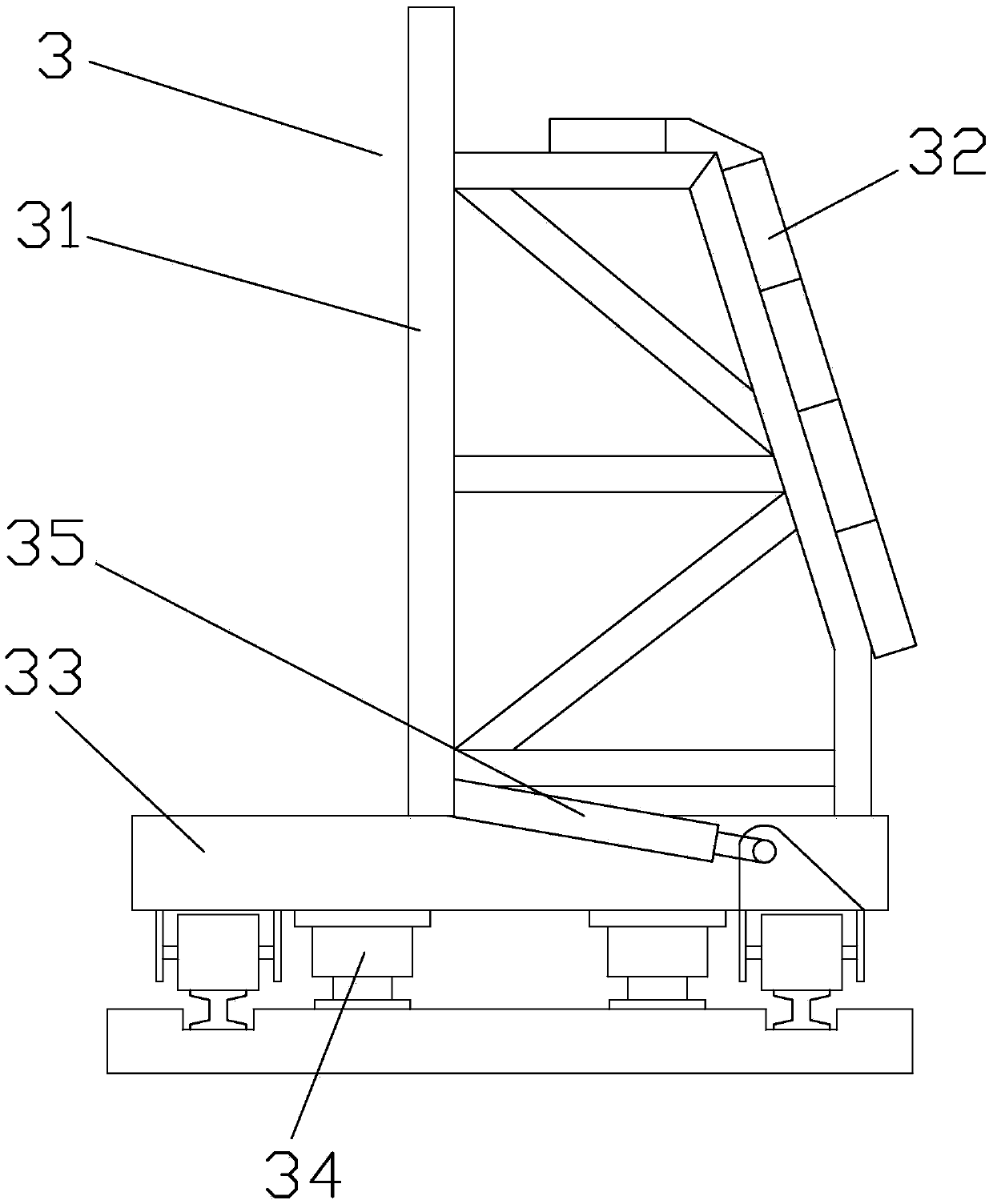

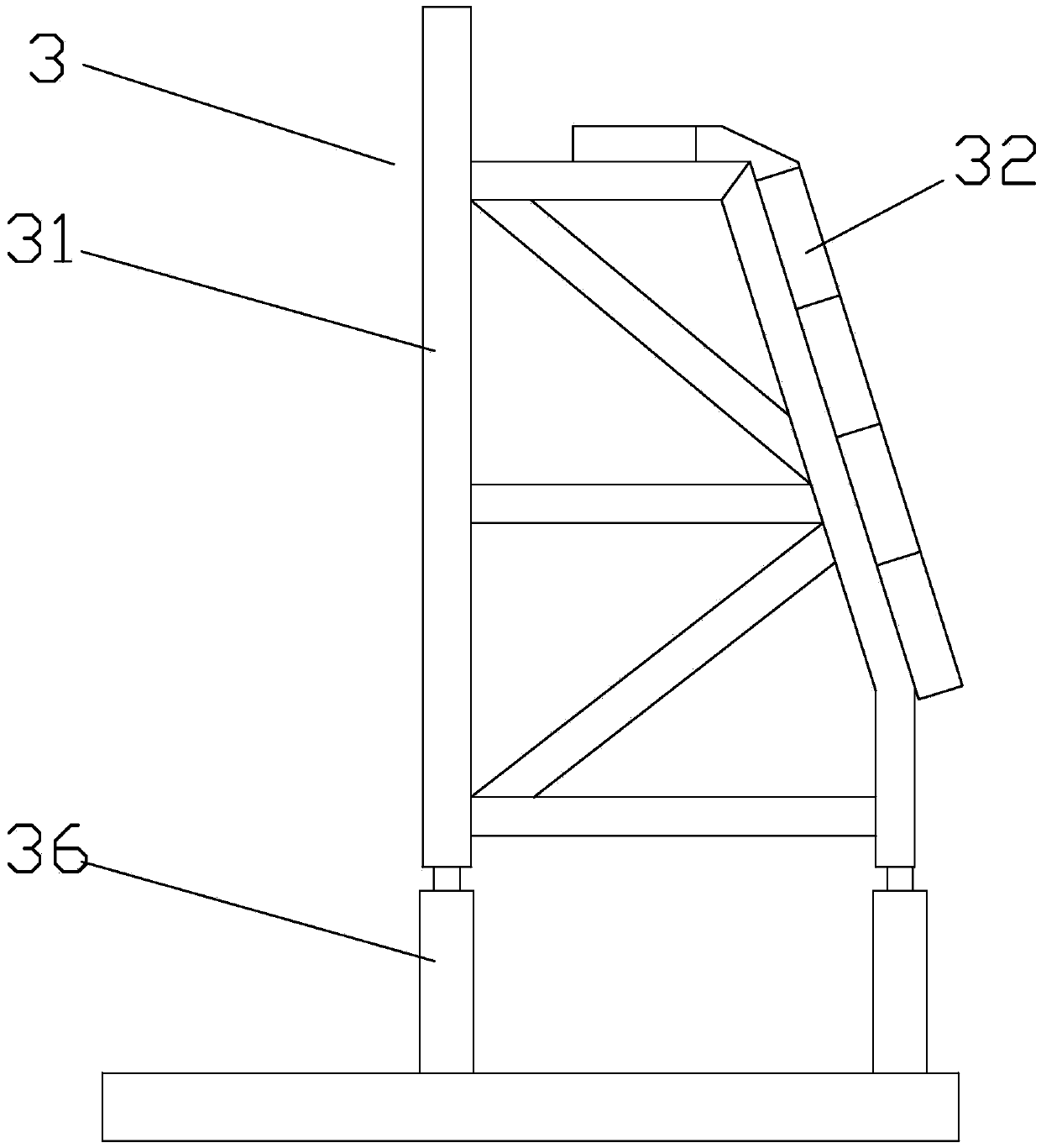

[0048] Step 2, install the template, the template is installed in the following order:

[0049] A. Install bottom mold 2, bottom mold 2 is installed as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com