Surface treatment method of aluminum alloy shell

A technology of surface treatment and aluminum alloy, which is applied in the direction of surface reaction electrolytic coating, metal processing equipment, anodic oxidation, etc., can solve the problem that the appearance effect of aluminum alloy is not rich and diverse, so as to achieve rich and diverse surface appearance, improve corrosion resistance, Appearance of various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

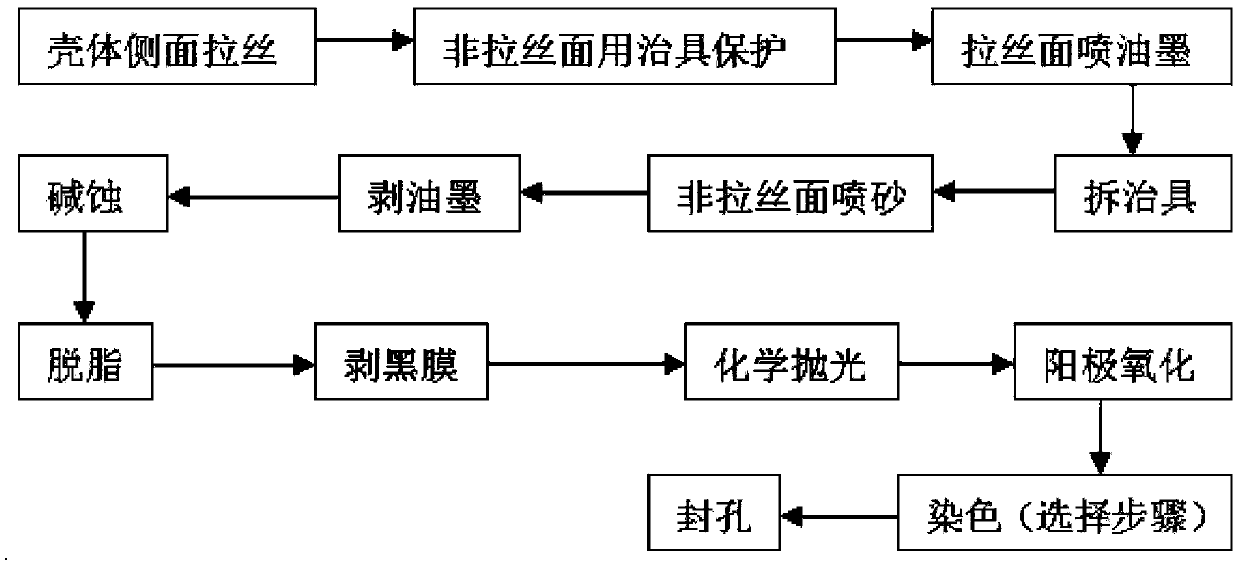

[0058] The surface treatment process of the aluminum alloy shell is as follows: figure 1 As shown, the surface treatment process includes the following steps:

[0059] S1 side drawing: drawing the side of the aluminum alloy shell to obtain a drawing surface;

[0060] S2 protects the non-drawn surface with a jig;

[0061] S3 Spray sandblasting ink on the drawing surface;

[0062] S4 removes the jig;

[0063] S5 non-drawing surface sandblasting: sandblasting the non-drawing surface of the aluminum alloy shell;

[0064] S6 peeling ink: peel off the ink on the brushed surface;

[0065] S7 Alkali etching: degrease the aluminum alloy shell after peeling off the ink;

[0066] S8 Degreasing: Alkali etching the degreased aluminum alloy shell;

[0067] S9 stripping black film: remove the black film produced after alkali etching treatment;

[0068] S10 chemical polishing: chemically polish the aluminum alloy shell after removing the black film;

[0069] S11 Anodizing: Anodize the...

Embodiment 2

[0073] A surface treatment process for an aluminum alloy shell, comprising the steps of:

[0074] S1 side wire drawing: horizontally draw the side of the aluminum alloy shell with a wire drawing machine, the model of the wire drawing wheel is 800 mesh, the wire drawing speed is 30m / min, the speed of the wire drawing machine is 1800r / min, and the outlet range is 0.1mm, and the brushed surface;

[0075] S2 inkjet drawing surface: protect the non-drawing surface with a jig, then spray sandblasting ink on the drawing surface, and then remove the jig to get an aluminum alloy shell with side inkjet;

[0076] S3 Sandblasting on the non-drawing surface: Sandblasting the non-drawing surface of the aluminum alloy shell, spraying one or a combination of at least two of glass sand, steel sand or zircon sand, the sand mold is 220 mesh, The sand size is 0.05mm, and the sandblasting pressure is 2.5kg / cm 2 , the blasting speed is 15m / min;

[0077] S4 peeling ink: peel off the ink on the br...

Embodiment 3

[0087] A surface treatment process for an aluminum alloy shell, comprising the steps of:

[0088] S1 side wire drawing: longitudinally draw the side of the aluminum alloy shell with a wire drawing machine, the model of the wire drawing wheel is 20 mesh, the wire drawing speed is 2m / min, the speed of the wire drawing machine is 2400r / min, and the outlet range is 2.5mm. brushed surface;

[0089] S2 inkjet drawing surface: protect the non-drawing surface with a jig, then spray sandblasting ink on the drawing surface, and then remove the jig to get an aluminum alloy shell with side inkjet;

[0090] S3 Sandblasting on the non-drawing surface: sandblasting the non-drawing surface of the aluminum alloy shell, spraying one or a combination of at least two of glass sand, steel sand or zircon sand, the sand mold is 80 mesh, The sand size is 0.178mm, and the sandblasting pressure is 1.0kg / cm 2 , the blasting speed is 8m / min;

[0091] S4 peeling ink: peel off the ink on the brushed sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com