Starting circuit and starting method of permanent magnet synchronous motor

A permanent magnet synchronous motor and starting circuit technology, which is applied in the direction of controlling generators, motor generators, electromechanical brakes, etc., can solve the problems of unsmooth switching between open and closed loops, and difficulty in starting with load, so as to shorten the start-up time and realize Sensorless start, the effect of reducing the angle difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

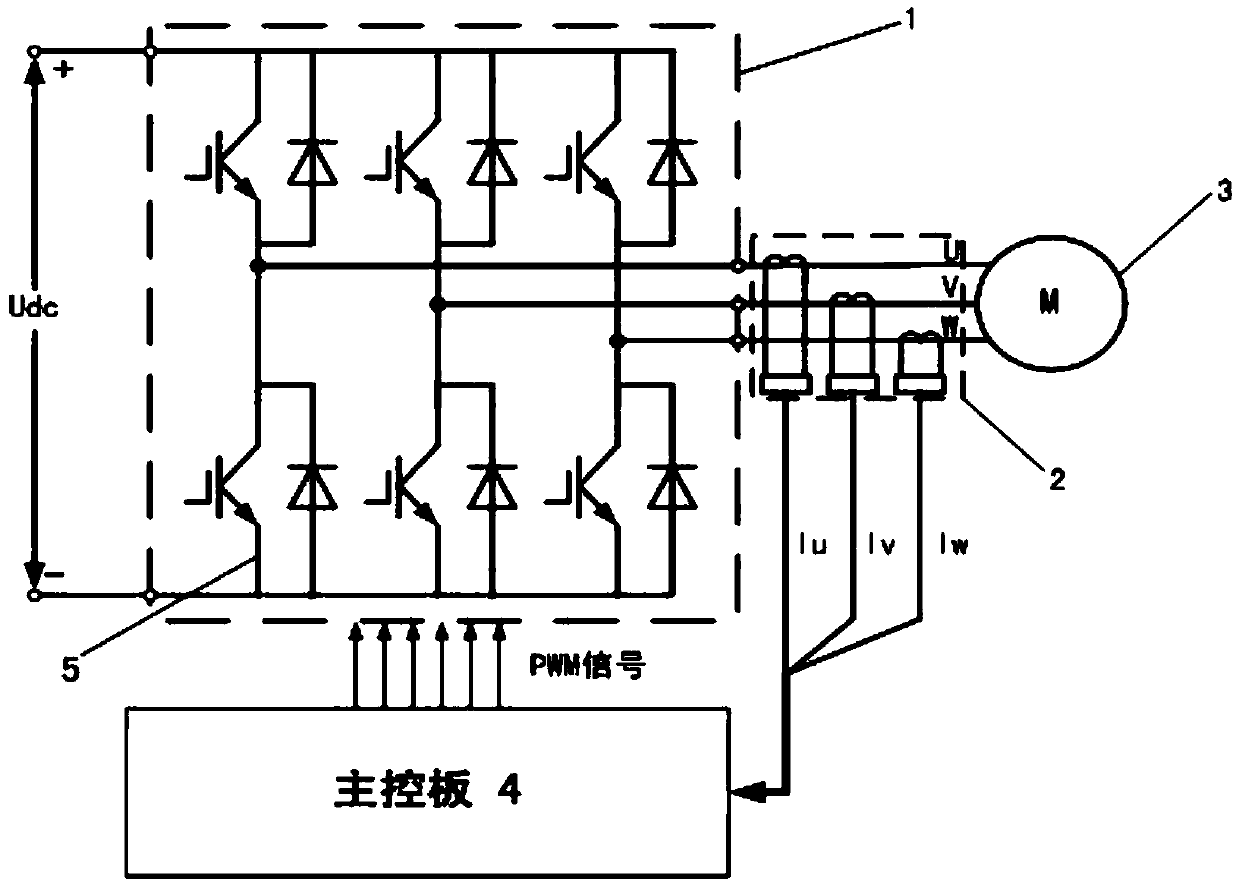

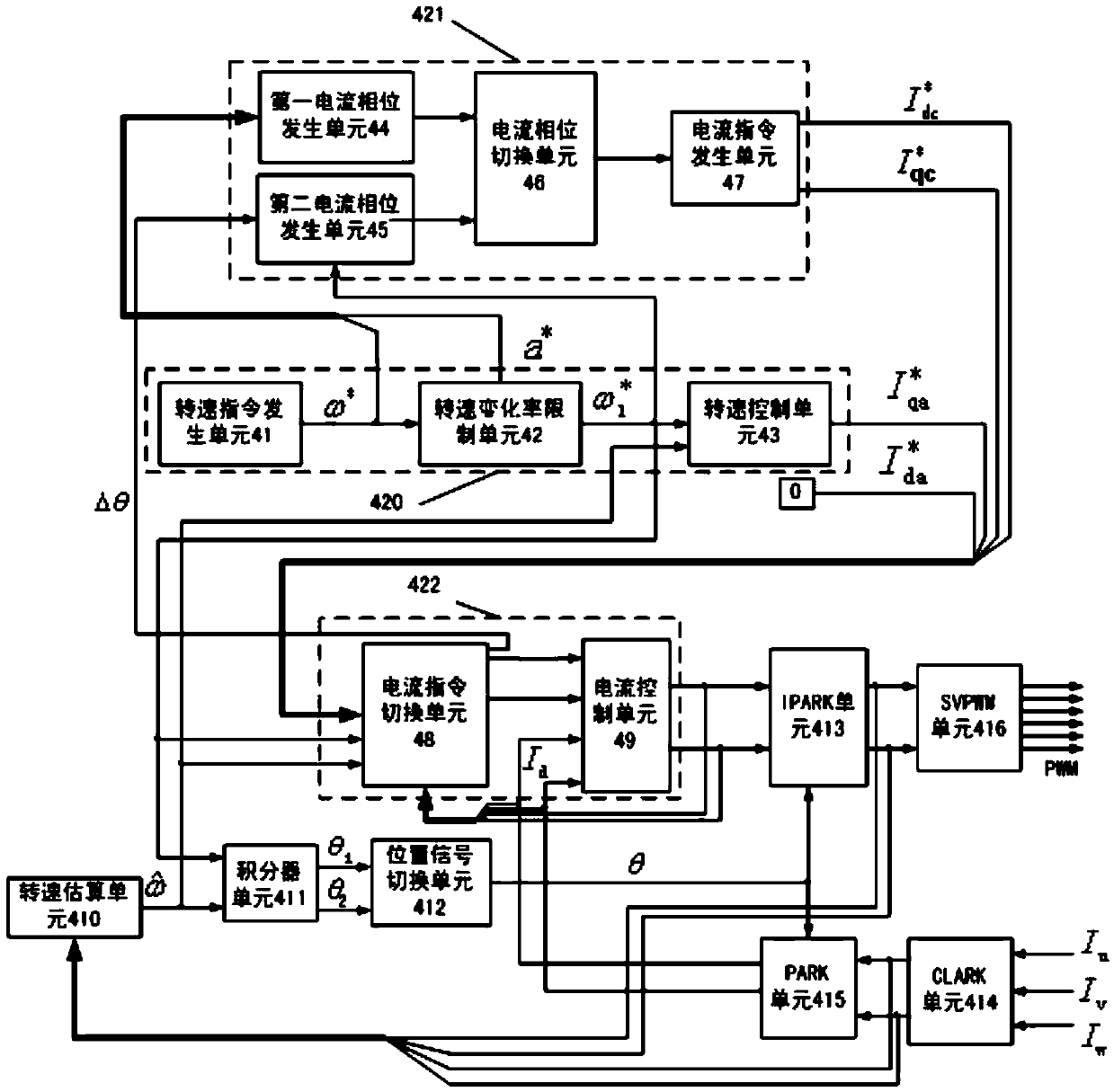

[0059] Such as figure 2 The illustrated embodiment is a schematic diagram of hardware involved in the present invention, including an inverter circuit 1 , three current sensors 2 , a motor 3 and a main control board 4 . The inverter circuit 1 includes 3 groups of IGBT modules 5 , the 3 groups of IGBT modules are electrically connected to the motor through 3 wires respectively, and the 3 current sensors are respectively located on the 3 wires to detect the three-phase current of the motor. The main control board includes various functional modules implementing sensorless vector control, specifically as image 3 shown. Mainly include: speed control module 420, starting current command generation module 421, current control module 422, speed estimation unit 410, integrator unit 411, position signal switching unit 412, IPARK unit 413, CLARK unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com