Ultra-thin even-temperature plate device and manufacturing method thereof

A manufacturing method and technology of a temperature equalizing plate, which are used in manufacturing tools, lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of difficulty in achieving a thickness of 1-2mm, and it is difficult to reduce the height and space of the cavity. The effect of cooling performance, reducing space height, and increasing the number of single machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

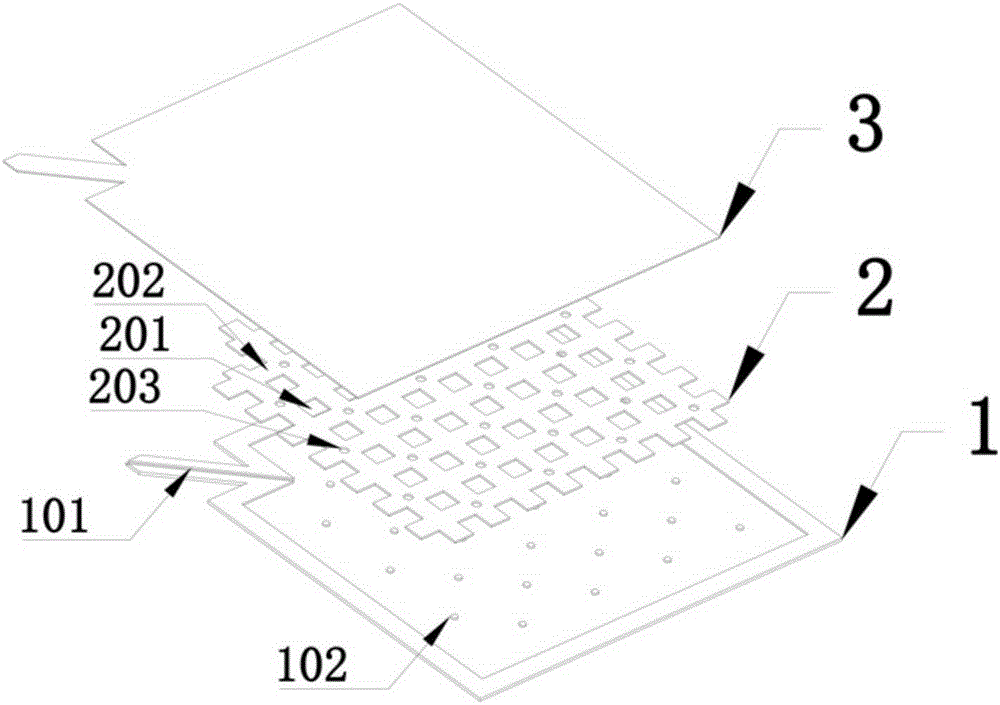

[0041] (1) Use 6063 aluminum alloy with a thickness of 5mm to process the bottom plate and upper cover plate structure, the depth of the bottom plate groove is 0.4mm, and the flatness requirement is within 0.05mm;

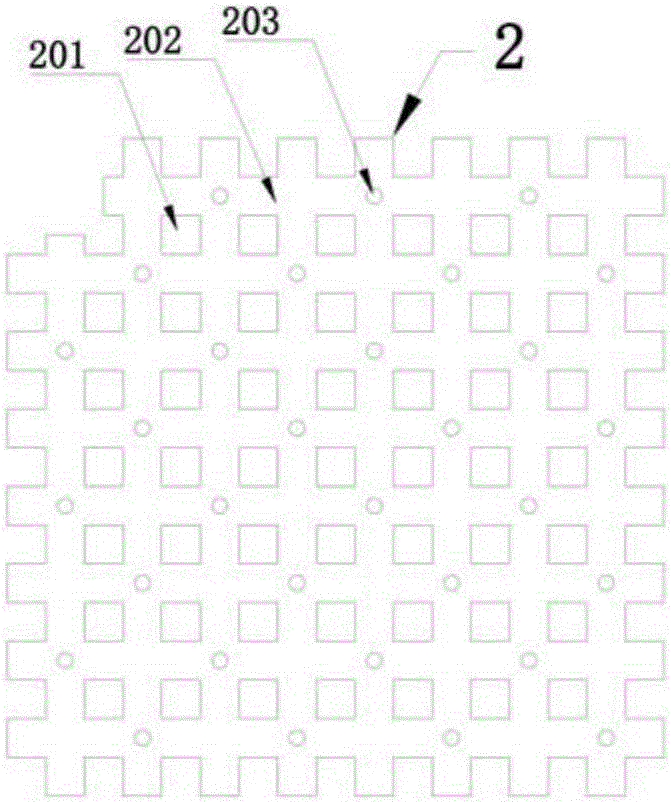

[0042] (2) Use 0.5mm porous nickel foam as the capillary core, and punch out a regular "#"-shaped structure with the tooling processed by tool steel, in which the side length of the middle rectangular hole is 5mm, and the width of the solid part of the capillary core is also 5mm;

[0043] (3) Assemble the capillary core in the groove of the bottom plate, and place and fix the upper cover plate correspondingly;

[0044] (4) Use vacuum pressurized diffusion welding to realize the welding connection between the bottom plate and the upper cover plate, and the vacuum degree during welding is required to reach 10 -4 pa, the maximum pressure of instant pressurization reaches 20Mpa;

[0045] (5) Use machining to flatten the two sides of the chamber after welding, requirin...

Embodiment 2

[0049] (1) Use TU1 copper material with a thickness of 5mm to process the structure of the bottom plate and the upper cover plate. The depth of the bottom plate groove is 0.4mm, and the flatness requirement is within 0.05mm;

[0050] (2) Use 0.5mm porous copper foam material as the capillary core, and punch out a regular "#"-shaped structure with the tooling processed by tool steel, in which the side length of the middle rectangular hole is 5mm, and the width of the solid part of the capillary core is also 5mm;

[0051] (3) Assemble the capillary core in the groove of the bottom plate, and place and fix the upper cover plate correspondingly;

[0052] (4) Use vacuum pressurized diffusion welding to realize the welding connection between the base plate and the upper cover plate, and the vacuum degree during welding is required to reach 10 -4 pa, pressurized pressure is within 2Mpa;

[0053] (5) Machining the two sides of the vapor chamber shell after welding to level off, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com