Intelligent shell breaking control system for aluminum electrolysis based on direct current stabilized power supply

A technology of a DC regulated power supply and a control system, applied in the field of aluminum electrolysis, can solve the problems of increasing the failure rate of the hammer head and shelling cylinder, increasing the heat loss of the electrolytic cell, increasing the consumption of aluminum fluoride salt, etc., so as to shorten the heating time and reduce the The effect of gourd head and smooth cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

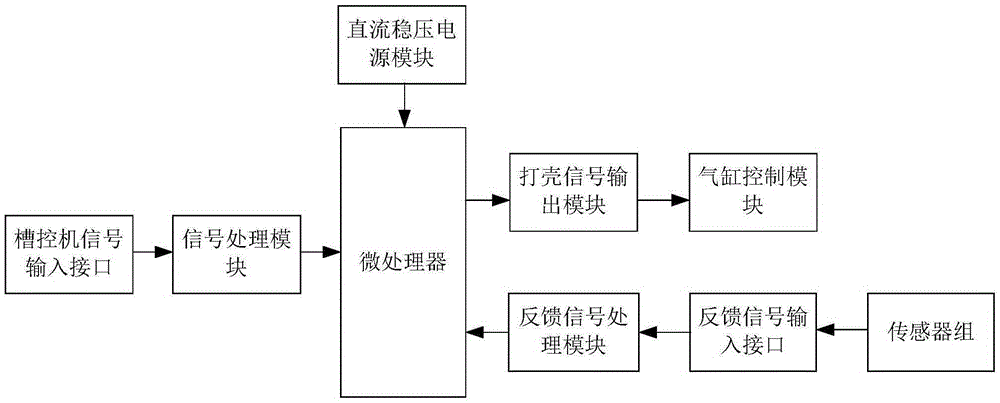

[0027] Such as figure 1 As shown, the intelligent shelling control system for aluminum electrolysis based on DC stabilized power supply of the present invention mainly consists of a microprocessor as a system control center, a DC stabilized power supply module connected to the microprocessor, a signal processing module, and a shelling control system. The shell signal output module and the feedback signal processing module, the groove control machine signal input interface connected with the signal processing module, the cylinder control module connected with the shelling signal output module, and the feedback signal input interface connected with the feedback signal processing module, and a sensor group connected to the feedback signal input interface.

[0028] Among them, the power module is used to provide working power for the whole control system; the signal input interface of the slot control machine is connected to the external slot control machine to receive the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com