Novel 3D printer and printing process control method thereof

A 3D printer and printer technology, applied in the direction of additive processing, etc., can solve the problems of equipment cost, maintenance cost, high material cost, toxicity of photosensitive resin raw materials, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] A novel 3D printer includes a printer body, a housing, and a computer loaded with a three-dimensional CAD model.

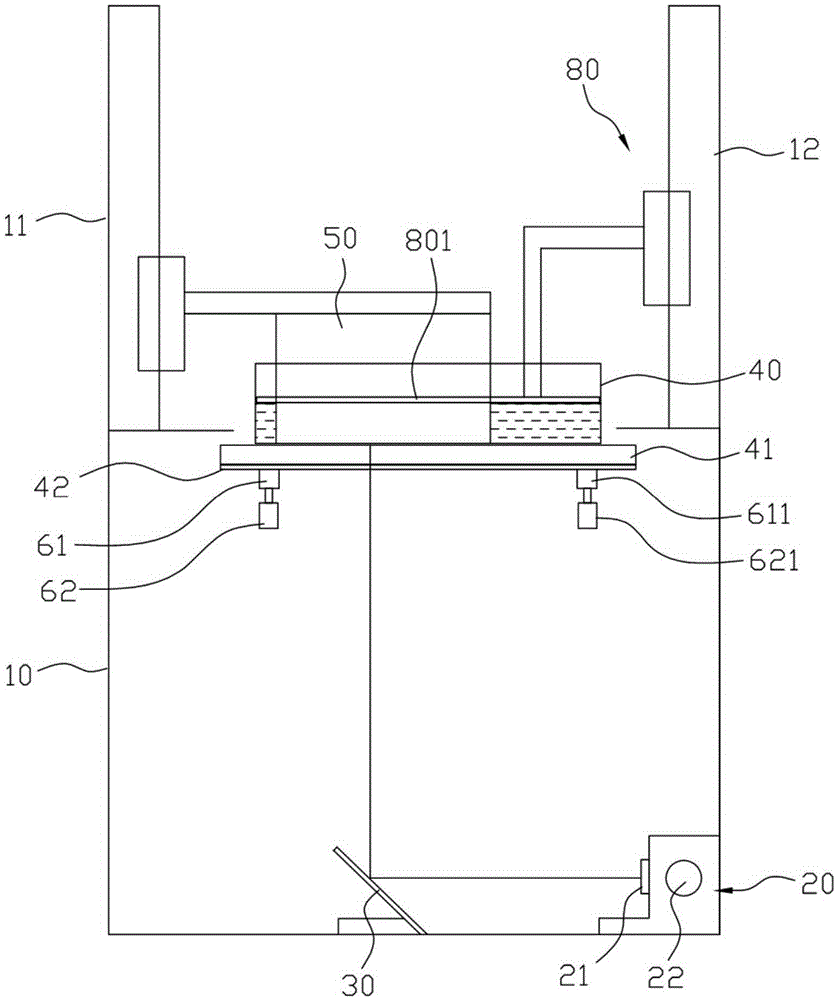

[0063] Such as figure 1 , the printer body includes a cabinet body 10 with a hollow chamber and a first bracket 11 extending upward along the rear side of the cabinet body, and a laser scanning device 20 is provided at the front end of the bottom of the hollow chamber body of the cabinet body, so The central part of the bottom of the hollow chamber of the cabinet body is provided with a reflector 30, a resin tank 40 is provided directly above the reflector, and a high-transmittance quartz glass 41 is fixed on the bottom surface of the resin tank. The quartz glass is fixed on the iron plate 42, an opening is provided on the top of the cabinet, and the opening communicates with the hollow chamber, and the resin tank is located in the opening on the top of the cabinet.

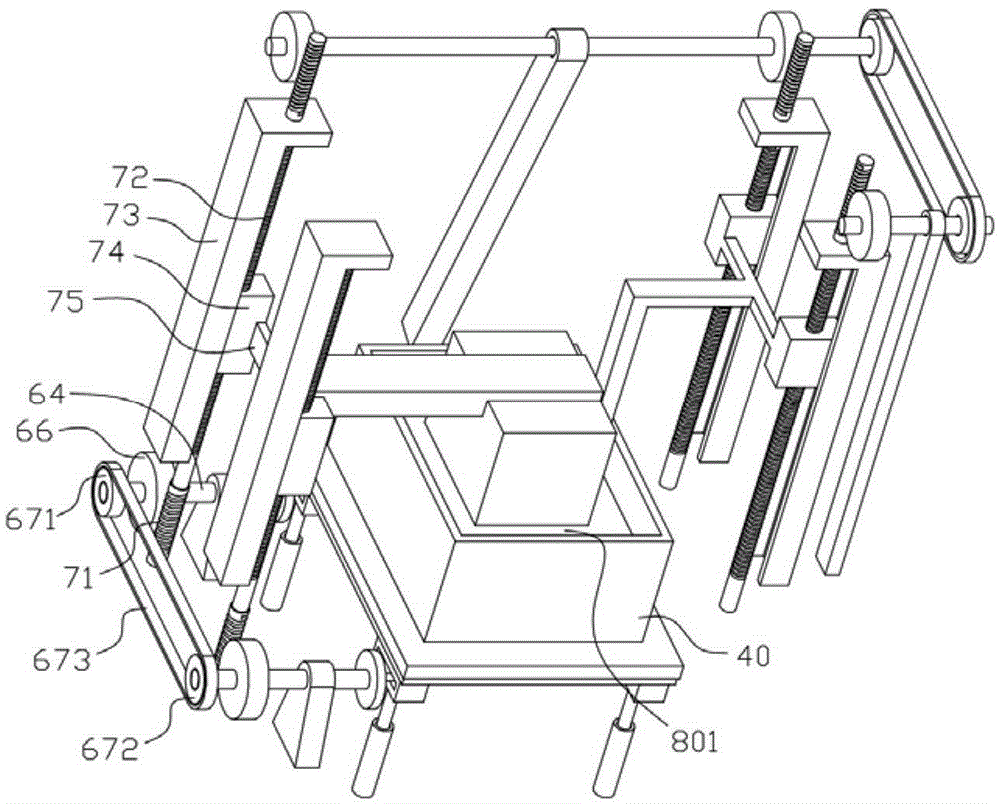

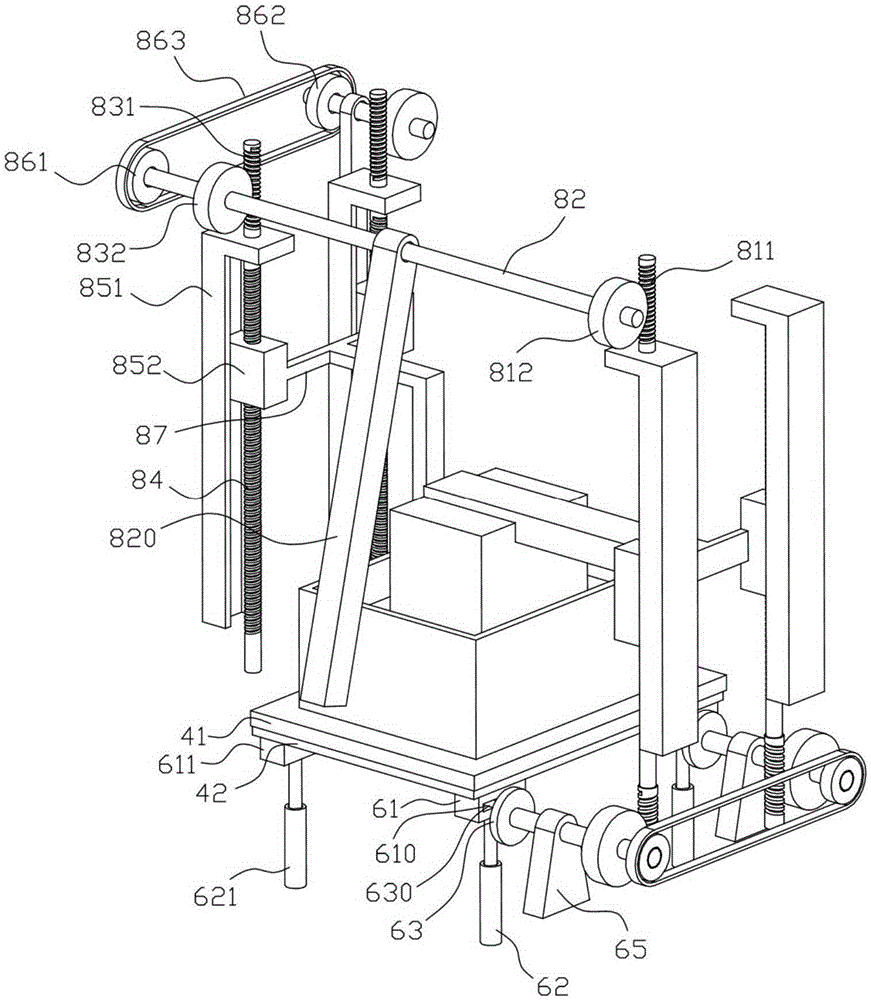

[0064] The bottom of the iron plate is provided with a first lifting device, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com