Laser forming method of TiC-Ti composite component

A composite material component and laser forming technology, which is applied in the direction of additive processing, etc., can solve the problems of large difference in bulk density, change of the design composition of the reinforcement phase, and uneven distribution of the reinforcement phase, so as to achieve controllable distribution and eliminate uneven distribution of TiC Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A TiC-Ti composite material automotive engine intake valve laser forming method, comprising the following processes:

[0020] 1. Raw material formula and pretreatment

[0021] The raw material formula is: 3.51wt.% of graphite, 0.15wt.% of mixed rare earth, and the balance of Ti; the raw material is in the form of powder, and the particle size of the powder is 50 microns; the metal Ti powder and the mixed rare earth powder are ball milled for 2 hours.

[0022] 2. Powder feeding and mixing

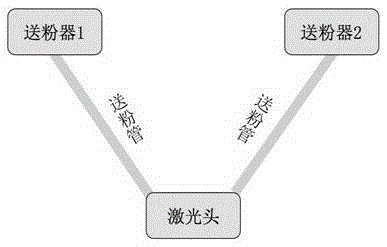

[0023] The powder feeding process is completed by a multi-hopper screw powder feeding mixing system. Ti powder and mixed rare earth powder are put into the first hopper, graphite powder is placed in the second hopper; two screw powder feeders feed powder at the same time, and pass through Adjust the screw speed to adjust the content of TiC generated locally in the component;

[0024] 3. Laser forming

[0025] The laser head of the laser forming adopts 2 coaxial discontinuous nozzle...

Embodiment 2

[0028] A TiC-Ti composite material automotive engine connecting rod laser forming method, comprising the following processes:

[0029] 1. Raw material formula and pretreatment

[0030] The raw material formula is: graphite 2.36wt.%, mixed rare earth 0.11wt.%, Ti balance; the raw material is in the form of powder, and the powder particle size is 40 microns; metal Ti powder and mixed rare earth powder are ball milled together for 3 hours;

[0031] 2. Powder feeding and mixing

[0032] The powder feeding process is completed by a multi-hopper screw powder feeding mixing system. Ti powder and mixed rare earth powder are put into the first hopper, graphite powder is placed in the second hopper; two screw powder feeders feed powder at the same time, and pass through Adjust the screw speed to adjust the content of TiC generated locally in the component;

[0033] 3. Laser forming

[0034] The powder in the multi-hopper is air-carried to the laser head with 3 pipelines for laser for...

Embodiment 3

[0037] A TiC-Ti high temperature valve sleeve laser forming method, comprising the following process:

[0038] 1. Raw material formula and pretreatment

[0039] The raw material formula is: 4.55wt.% of graphite, 0.22wt.% of mixed rare earth, and the balance of Ti; the raw material is in the form of powder, and the powder particle size is 200 microns; the metal Ti powder and the mixed rare earth powder are ball milled together for 4 hours.

[0040] 2. Powder feeding and mixing

[0041] The powder feeding process is completed by a multi-hopper screw powder feeding mixing system. Ti powder and mixed rare earth powder are put into the first hopper, graphite powder is placed in the second hopper; two screw powder feeders feed powder at the same time, and pass through The screw speed adjusts the content of TiC generated locally in the component.

[0042] 3. Laser forming

[0043]The powder in the multi-hopper is air-carried to the laser head with two pipelines for laser forming. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com