High polished buckwheat ratio processing process of buckwheat

A processing technology and high-polished rice technology, which is applied in the field of buckwheat high-polished rice processing technology, can solve the problems of low secondary husking rate and achieve remarkable effects, promote loosening, and increase color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

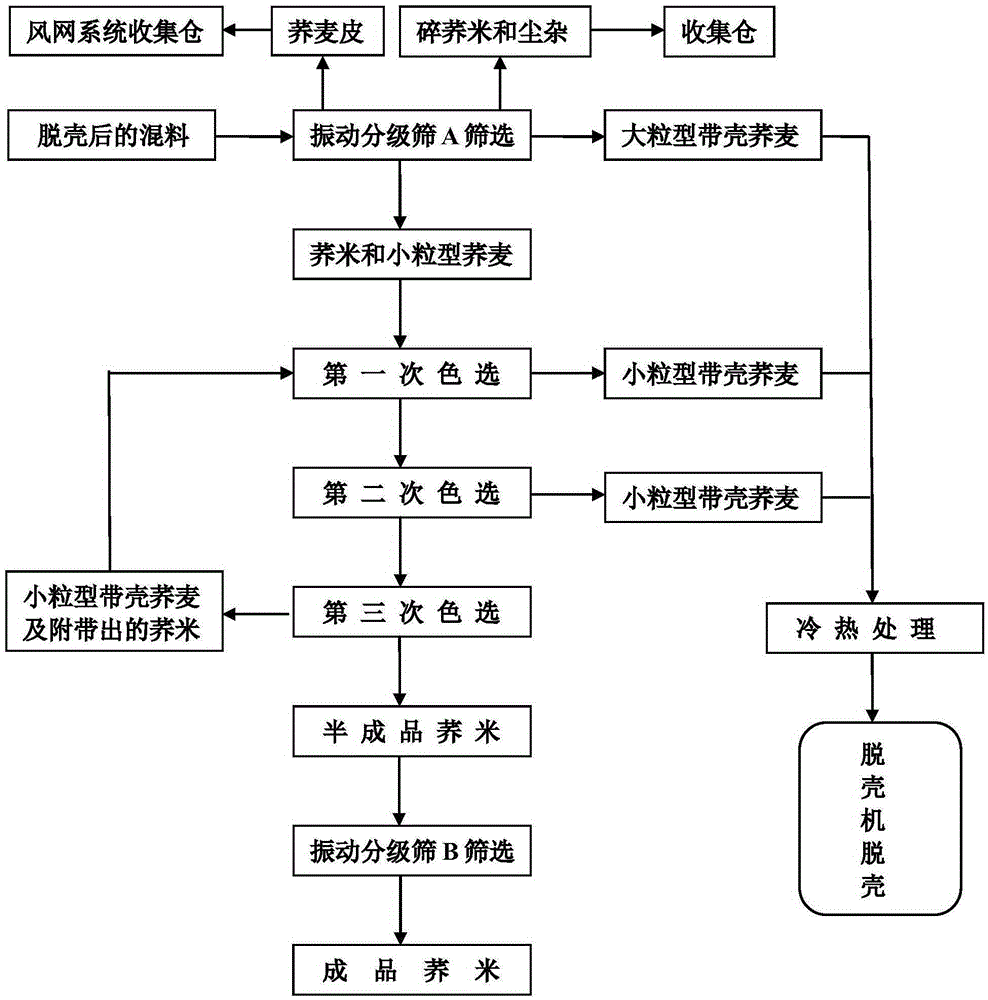

[0037] A kind of buckwheat high polished rice rate processing technology, comprises the steps:

[0038] 1) Screening: the mixture containing a small part of buckwheat husk, buckwheat and shelled buckwheat after husking is first screened through a vibrating grading sieve A with upper and lower screens, and the first paddy separation is carried out, and the buckwheat husk is The suction-type vertical suction separator is sent to the collection bin of the air net system; the upper sieve of the sieve body is large-grain hulled buckwheat, accounting for 14% of the mass of the hulled buckwheat in the mixture; the lower sieve The under-sieve is broken buckwheat and dust, and enters the collection bin; the sieve on the lower sieve is buckwheat and small-grain shelled buckwheat, wherein the mass ratio of buckwheat is 48%;

[0039] Described mixed material is the mixed material after buckwheat husking rate is 46% after shelling;

[0040] The vibrating grading screen A upper screen and ...

Embodiment 2

[0059] A kind of buckwheat high polished rice rate processing technology, comprises the steps:

[0060] 1) Screening: the mixture containing a small part of buckwheat husk, buckwheat and shelled buckwheat after husking is first screened through a vibrating grading sieve A with upper and lower screens, and the first paddy separation is carried out, and the buckwheat husk is The suction-type vertical suction separator is sent to the collection bin of the air net system; the upper sieve of the sieve body is large-grain shell buckwheat, accounting for 12% of the mass of shell buckwheat in the mixture; the lower sieve The under-sieve is broken buckwheat and dust, and enters the collection bin; the sieve on the lower sieve is buckwheat and small-grain shelled buckwheat, wherein the mass ratio of buckwheat is 46%;

[0061] Described mixed material is the mixed material after buckwheat husking rate is 45% after shelling;

[0062] The vibrating grading screen A upper screen and the lo...

Embodiment 3

[0081] A kind of buckwheat high polished rice rate processing technology, comprises the steps:

[0082] 1) Screening: the mixture containing a small part of buckwheat husk, buckwheat and shelled buckwheat after husking is first screened through a vibrating grading sieve A with upper and lower screens, and the first paddy separation is carried out, and the buckwheat husk is The suction-type vertical suction separator is sent to the collection bin of the air net system; the upper sieve of the sieve body is large-grain hulled buckwheat, accounting for 15% of the mass of the hulled buckwheat in the mixture; the lower sieve The under-sieve is broken buckwheat and dust, which enters the collection bin; the over-sieve of the lower sieve is buckwheat and small-grain shelled buckwheat, wherein the mass ratio of buckwheat is 50%;

[0083] Described mixed material is the mixed material after buckwheat husking rate is 47% after shelling;

[0084] The vibrating grading screen A upper scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com