A composition for treating dry socket and its preparation method

A composition and dry socket technology, applied in the field of oral care, can solve the problems of being unusable, having no antibacterial effect, and being unable to prevent wound tissue infection, etc., achieving the effect of preventing bacterial infection, good hemostasis effect, and convenient clinical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

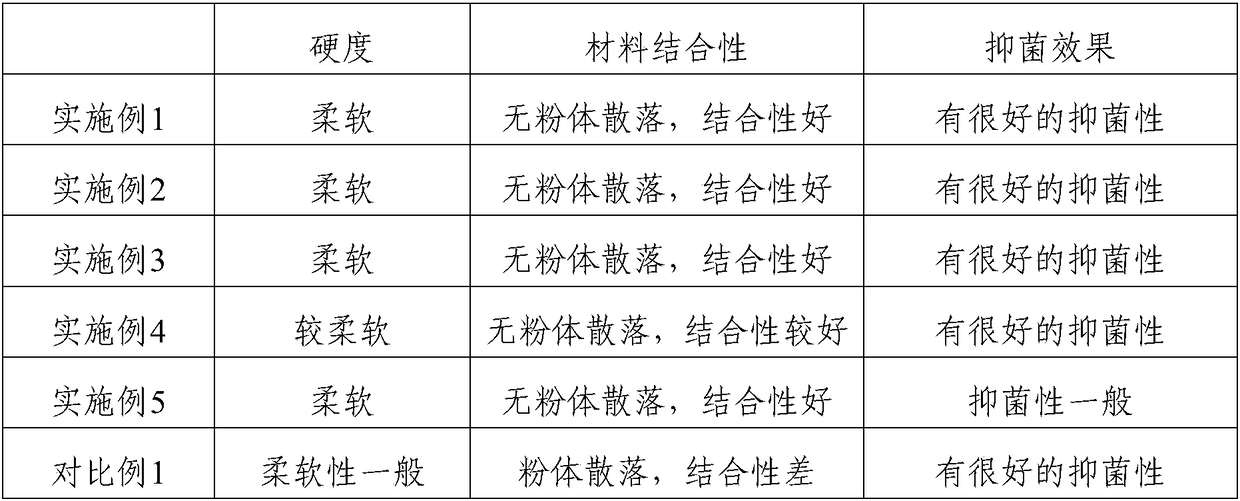

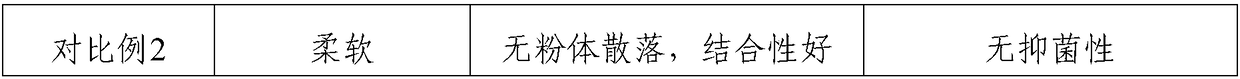

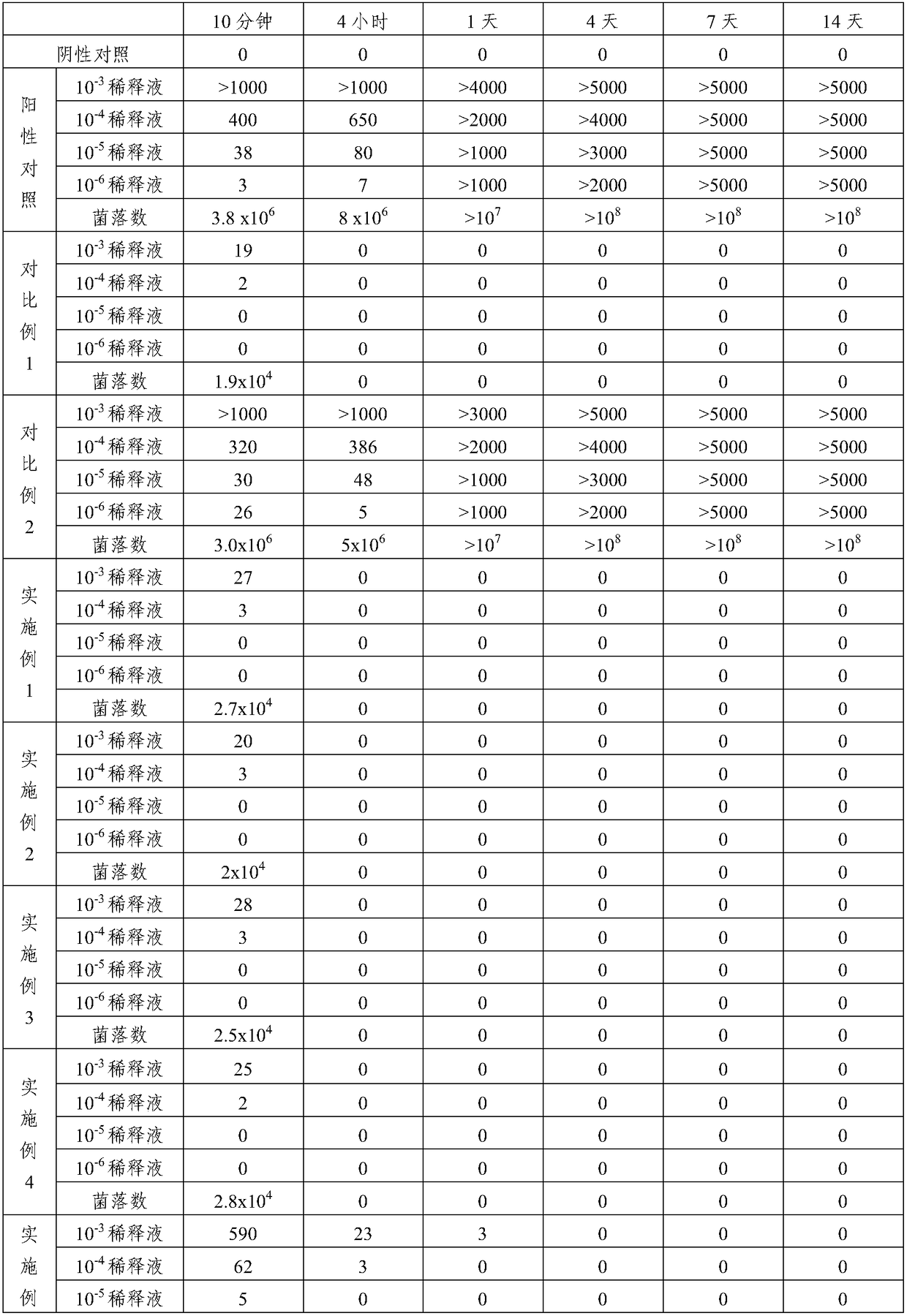

Examples

Embodiment 1

[0056] 1. Dissolution of PVA: Dissolve PVA in a container, the mass ratio of PVA to distilled water is 1:7. The PVA can be completely dissolved by dissolving for 20 minutes at a temperature of 70°C and a stirring speed of 350r / min.

[0057] 2. Acetalization: take 30g of completely dissolved PVA, add 4.5g of starch, stir evenly at room temperature (rotational speed is about 400r / min), then add 5.0mL of formaldehyde, 1.5mL of pentane, 5.0mL of sulfuric acid, and continue to stir for 5min , immediately put into the oven for curing for 1h after completion (the oven temperature is constant at 40°C). The solidified obtained sponge washes away the starch of the pore filling agent with clear water to obtain a medical sponge.

[0058] 3. Take 0.1g of sodium hyaluronate and add 10mL of distilled water to prepare sodium hyaluronate gel.

[0059] 4. Take 0.1g of bioactive mineral powder, add it to sodium hyaluronate gel, and stir evenly. Take 0.2g of the medical sponge prepared in step...

Embodiment 2

[0062] 1. Dissolution of PVA: Dissolve PVA in a container, the mass ratio of PVA to distilled water is 1:7. The PVA can be completely dissolved by dissolving for 20 minutes at a temperature of 70°C and a stirring speed of 350r / min.

[0063] 2. Acetalization: take 30g of completely dissolved PVA, add 4.5g of starch, stir evenly at room temperature (rotational speed is about 400r / min), then add 5.0mL of formaldehyde, 1.5mL of pentane, 5.0mL of sulfuric acid, and continue to stir for 5min , immediately put into the oven for curing for 1h after completion (the oven temperature is constant at 40°C). The solidified obtained sponge washes away the starch of the pore filling agent with clear water to obtain a medical sponge.

[0064] 3. Take 0.1g of sodium hyaluronate and add 10mL of distilled water to prepare sodium hyaluronate gel.

[0065] 4. Take 0.2g of bioactive mineral powder, add it to sodium hyaluronate gel, and stir evenly. Take 0.25g of the medical sponge prepared in ste...

Embodiment 3

[0068] 1. Dissolution of PVA: Dissolve PVA in a container, the mass ratio of PVA to distilled water is 1:7. The PVA can be completely dissolved by dissolving for 20 minutes at a temperature of 70°C and a stirring speed of 350r / min.

[0069] 2. Acetalization: Take 30g of completely dissolved PVA, add 4.5g of starch, stir evenly at room temperature (rotational speed is about 400r / min), then add 5.0mL formaldehyde, 1.5mL pentane, 5.0mL sulfuric acid in sequence, and continue stirring for 5min , immediately put into the oven for curing for 1h after completion (the oven temperature is constant at 40°C). The solidified obtained sponge washes away the starch of the pore filling agent with clear water to obtain a medical sponge.

[0070] 3. Take 0.1g of sodium hyaluronate and add 10mL of distilled water to prepare sodium hyaluronate gel.

[0071] 4. Take 0.15g of bioactive mineral powder, add it to sodium hyaluronate gel, and stir evenly. Take 0.15g of the medical sponge prepared i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com