A method of providing fiber web making furnish with filler, and paper or paper board

一种纤维网、纤维的技术,应用在纸或纸板领域,能够解决高投资、能量、运行和维护成本等问题,达到改进运行性能、节省使用、降低消耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

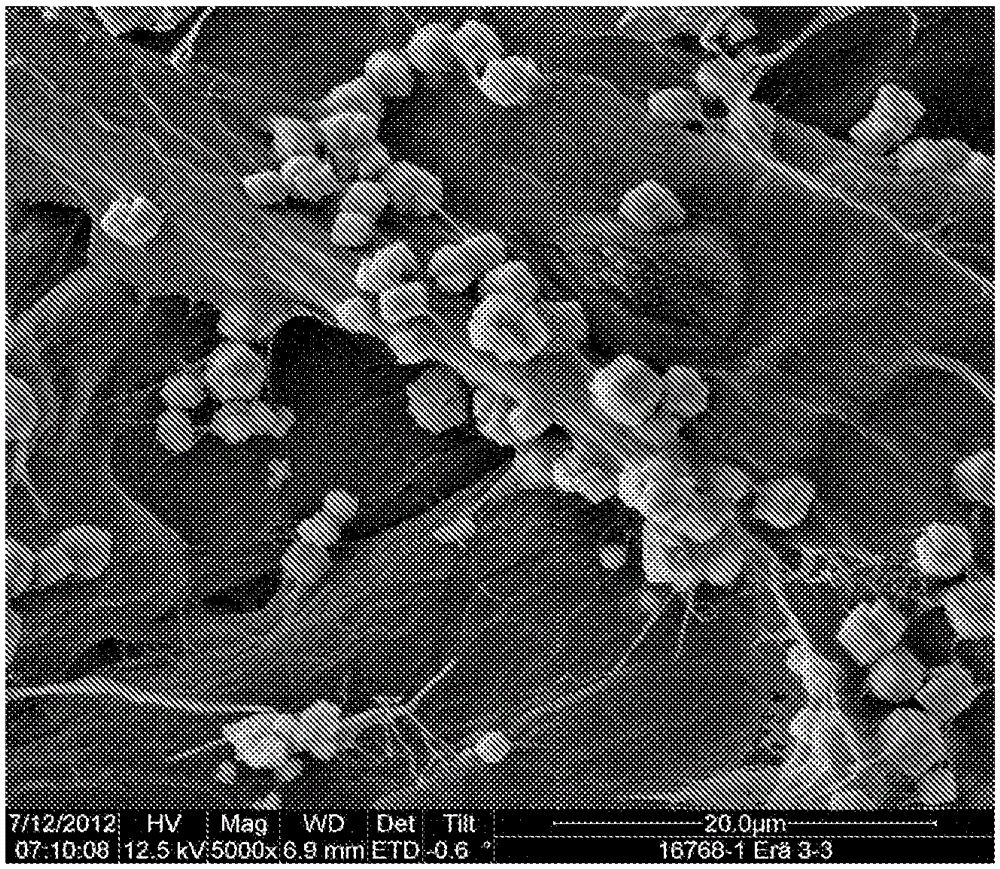

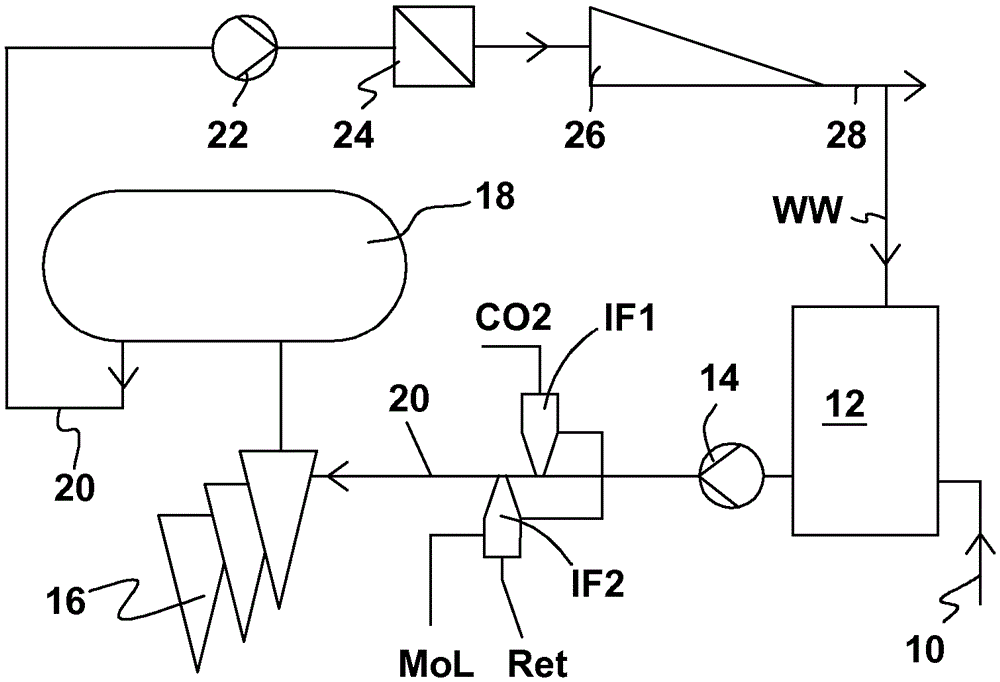

[0055] In Experiment 1, Sample 1, the reference pulp, was ECF bleached (elemental chlorine free) undried and unrefined kraft birch pulp with a consistency of approximately 1%, which corresponds to a normal paper machine headbox consistency. 500 grams of the pulp were poured into a laboratory mixer having a bottom formed by a wire mesh and a valve and a filtrate conduit beneath the bottom for draining the filtrate from the sample. Also added to the mixer was conventional (ie produced off-site rather than in-line) PCC slurry, the amount of PCC added was adjusted to correspond to a typical filler level of 28% in dry fine paper. The pulp and PCC were stirred at 250 rpm for 60 seconds, after which the rotor speed was increased to 500 rpm for 30 seconds. The rotor of the mixer at a speed of 500 rpm generates shear forces comparable to those in the short circuit and headbox of a paper machine. After 30 seconds, the valve at the bottom of the mixer was opened and stirring was contin...

Embodiment 2

[0070] A second series of experiments was performed to first establish a benchmark by making handsheets on a pilot paper machine with a standard pulp recipe (highly refined bleached birch pulp) used to form the top surface layer of uncoated multilayer liquid packaging board point. Use handsheets to measure or determine multiple variables. The formulation used for benchmarking in Experiment 5 included 5% calcined kaolin (calculated by weight of dry furnish) as a filler to improve the whiteness and opacity of the handsheet.

[0071] After reaching the benchmark point, ie in Experiment 6, the calcined kaolin was exchanged for 6% in-line PCC, ie PCC made in the line of the papermaking slurry or furnish. A comparison can thus be made between paper or board made by conventional filler application and paper or board made using in-line PCC application.

[0072] In Experiment 7, PCC was produced in the line of the papermaking slurry to have a concentration of 6%. However, in this ex...

Embodiment 3

[0085] A third series of experiments was conducted to first establish a benchmark by manufacturing handsheets on a standard recipe for a pilot machine used to form the face layer of uncoated multilayer liquid packaging board, and to measure or determine a number of variables. The formulation for Benchmarking Experiment 9 included 5% calcined kaolin as a filler to improve the whiteness and opacity of the handsheet.

[0086] After reaching the benchmark point in Experiment 9, i.e. in Experiment 10, the calcined kaolin was exchanged for 5% off-line-PCC, i.e. PCC produced at a satellite mill and shipped to the paper mill as a slurry. Off-line-PCC is comparable to the on-site produced PCC solution mixed into the headbox stock used in the prior art.

[0087] In Experiment 11, PCC was produced in the line of the papermaking stock or furnish to a concentration of 5%. A comparison between conventional PCC application methods and online PCC application methods can thus be made.

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| base weight | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com