3D printing remote monitoring device and method

A remote monitoring device and 3D printing technology, which is applied in the electronic field, can solve the problems of the influence of the camera monitoring field of view, the existence of camera monitoring blind spots, and the inability to observe the working status and printed parts of the 3D printer nozzles, etc., to achieve a large camera monitoring range and flexible remote monitoring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

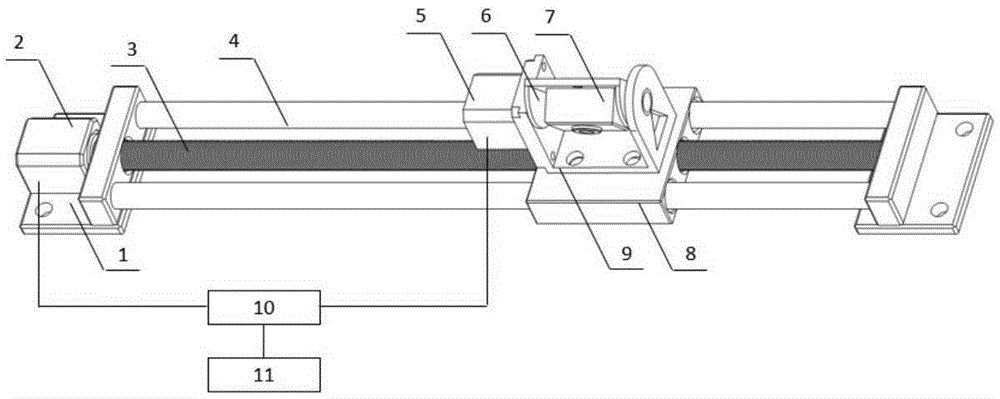

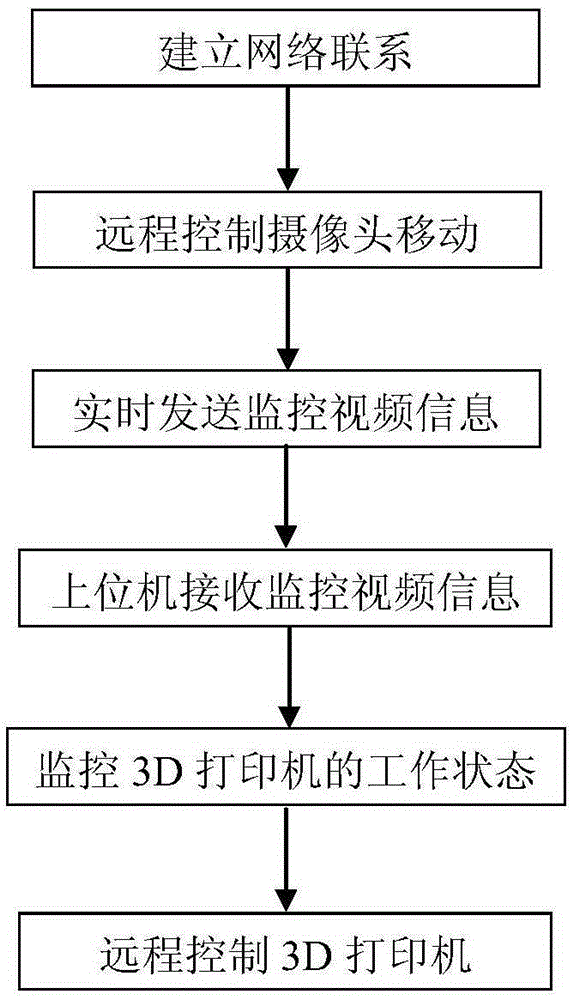

[0029] Refer to attached figure 1 , The device of the present invention includes a camera, a stepping motor, and a single-chip microcomputer. The camera (7) is installed on the pitch steering assembly, the pitch steering assembly is installed on the horizontal rail, and the horizontal rail is installed on the 3D printing frame through the base (1); the stepper motor is installed on the horizontal rail and the pitch steering assembly for driving The camera moves horizontally or tilts, wherein: the stepper motor (2) on the horizontal track is used to drive the camera (7) to move horizontally, and the stepper motor (5) on the pitch steering assembly is used to drive the camera (7) to tilt; The stepping motor (2) and the stepping motor (5) are connected to the single-chip microcomputer (11) through the stepping motor drive circuit (10); the single-chip microcomputer (11) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com