Negative electrode slurry for making negative electrode of lithium ion battery and preparation method thereof, negative electrode of lithium ion battery and battery

A lithium-ion battery and negative electrode slurry technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as agglomeration, nano-silicon powder floating slurry, and reduced battery cycle life. Achieve the effect of solving light specific gravity, ensuring uniform distribution, reducing re-agglomeration and segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Composition of negative electrode slurry:

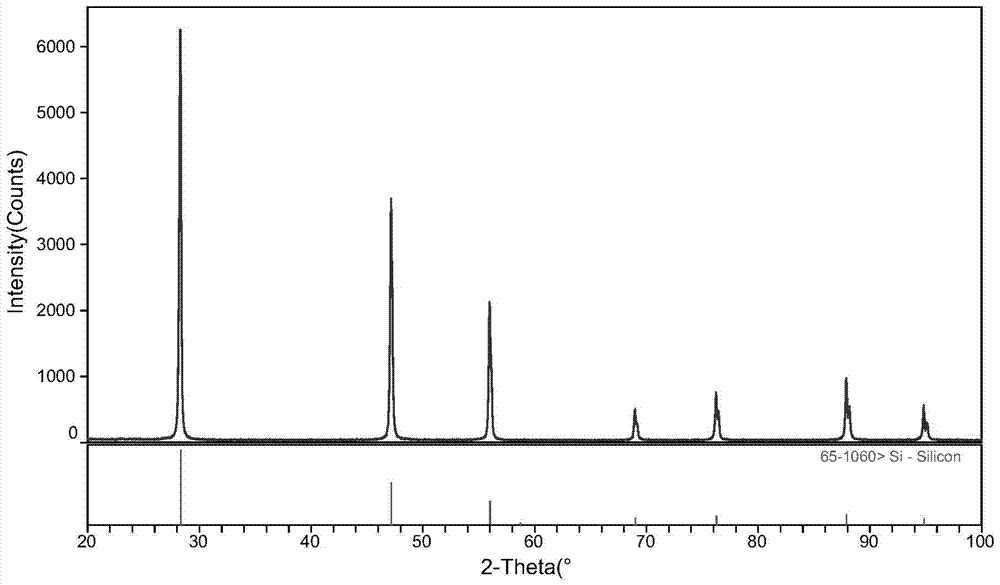

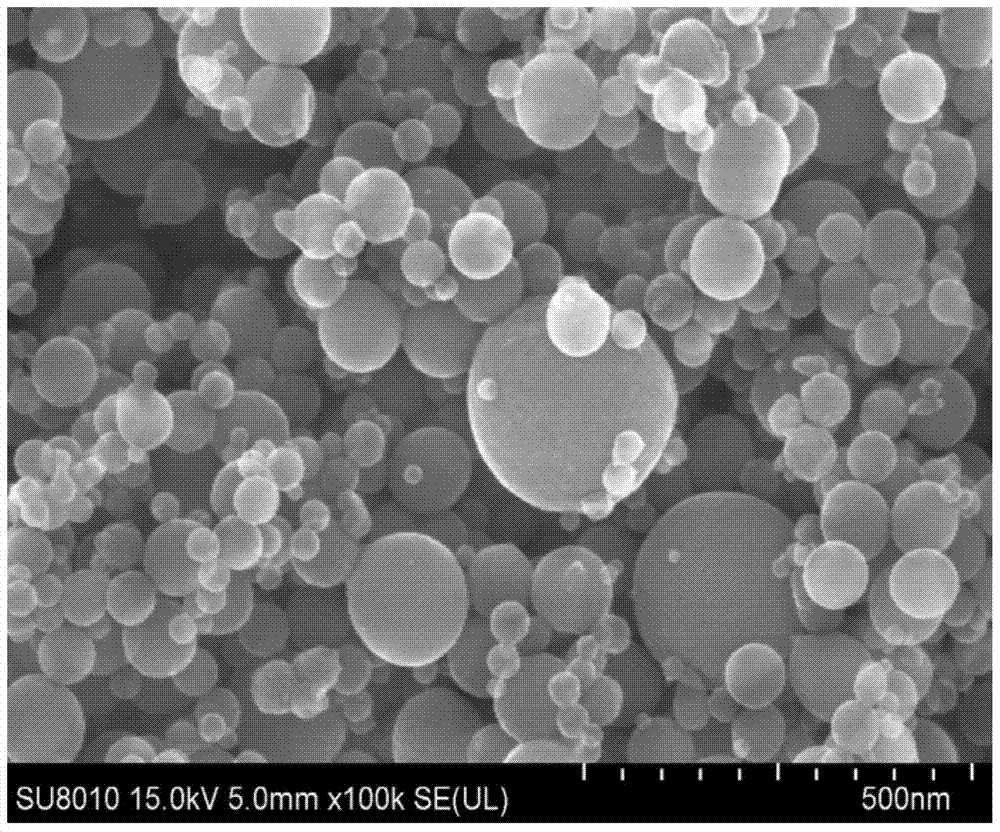

[0028] Nano-silica powder (the particle diameter in BET is 64nm, and its XRD diffraction pattern is as follows figure 1 As shown, its SEM morphology is as figure 2 Shown) 0.32g (accounting for 8wt% of the active material), Fangda Carbon New Material Technology Co., Ltd. FDF-318 type graphite powder (for active material) 3.68g (accounting for 92wt% of the active material), Chengdu Yindi Le Power Technology Co., Ltd. LA132 water-based adhesive (for binder) 0.5g, TIMREX KS6 conductive graphite (for conductive agent) 0.5g, solvent 15g (including water 7.5g, absolute ethanol 7.5g, mix well).

[0029] 2. Preparation of negative electrode sheet:

[0030] 1) Take 0.32g of nano-silica powder and add it to 2.88g of ethylene glycol solution, ultrasonically disperse (power 1200W), and use ice-water mixture to cool at the same time to prevent the dispersion from overheating, and use a nano-laser particle size analyzer to check the n...

Embodiment 2

[0045] 1. Composition of negative electrode slurry:

[0046] Nano silicon powder (particle size in BET is 64nm) 0.4g (accounting for 10wt% of active material), Fangda Carbon New Material Technology Co., Ltd. FDF-318 model graphite powder (for active material) 3.6g (accounting for active material 90% by weight), Chengdu Yindile Power Technology Co., Ltd. LA132 water-based adhesive (for binder) 0.5g, TIMREX KS6 conductive graphite (for conductive agent) 0.5g, solvent 15g (including water 7.5 g, acetone 7.5g, the two are mixed uniformly).

[0047] 2. Preparation of negative electrode sheet:

[0048] With embodiment 1.

[0049] 3. Assembly of test battery:

[0050] With embodiment 1. The assembled battery was charged and discharged at a current density of 100mAh / g, and the negative electrode capacity and cycle life were tested. The results are shown in Table 1 below.

Embodiment 3

[0052] 1. Composition of negative electrode slurry:

[0053] Nano silicon powder (BET particle diameter is 64nm) 0.2g (accounting for 5wt% of active material), Fangda Carbon New Material Technology Co., Ltd. FDF-318 model graphite powder (for active material) 3.8g (accounting for active material 95wt%), Chengdu Yindile Power Technology Co., Ltd. LA133 water-based adhesive (for binder) 0.5g, TIMREX KS6 conductive graphite (for conductive agent) 0.5g, solvent 15g (including water 7.5 g, acetone 7.5g, the two are mixed uniformly).

[0054] 2. Preparation of negative electrode sheet:

[0055] With embodiment 1.

[0056] 3. Assembly of test battery:

[0057] With embodiment 1. The assembled battery was charged and discharged at a current density of 100mAh / g, and the negative electrode capacity and cycle life were tested. The results are shown in Table 1 below.

[0058] Table 1

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com