A pre-selection high-efficiency pulping equipment suitable for wide particle size flotation

A flotation and slurry mixing technology, which is used in flotation, mixers with rotating stirring devices, transportation and packaging, etc. The problems of poor adaptability of feeding conditions can improve the probability of collision contact, enhance the flotation effect, and improve the stability of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

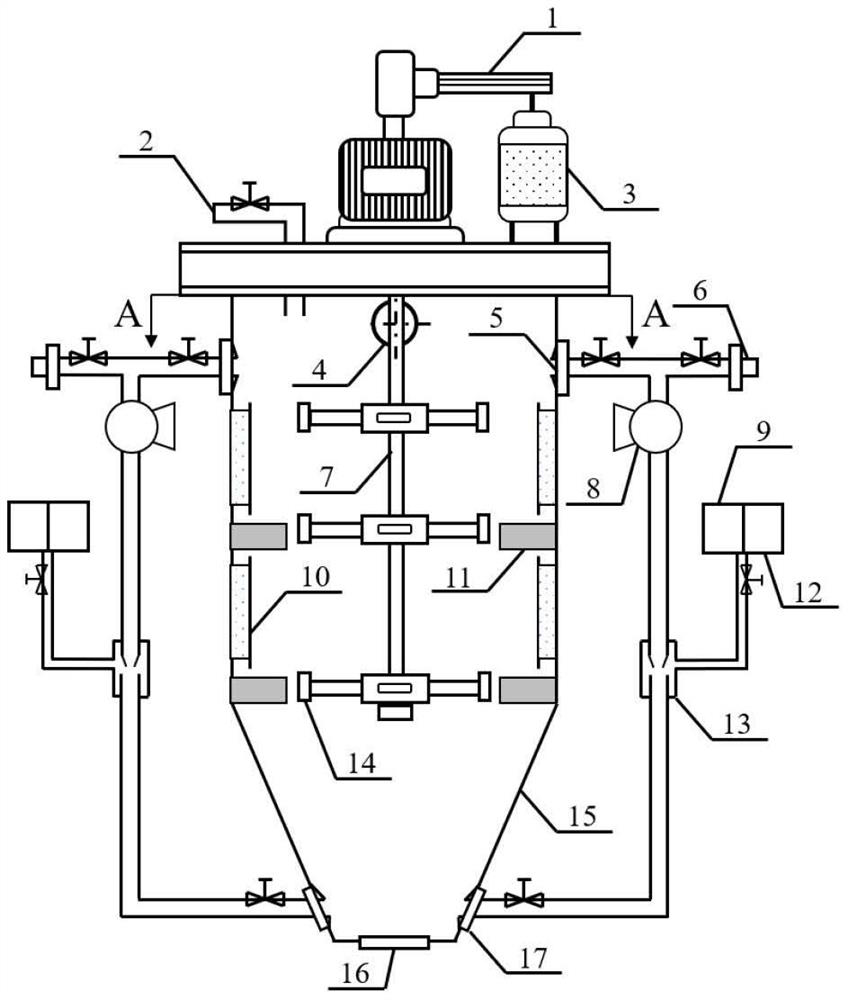

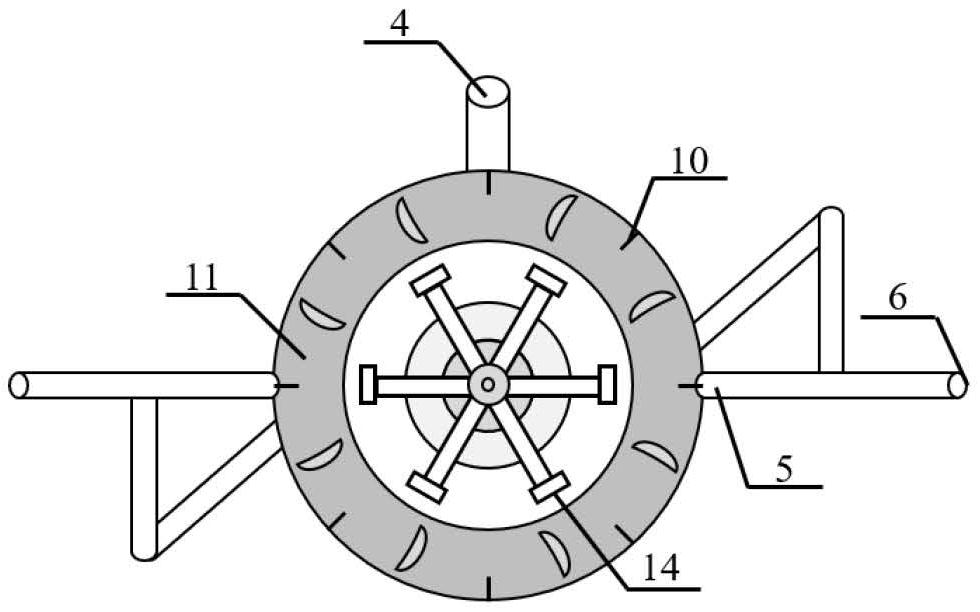

[0022] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

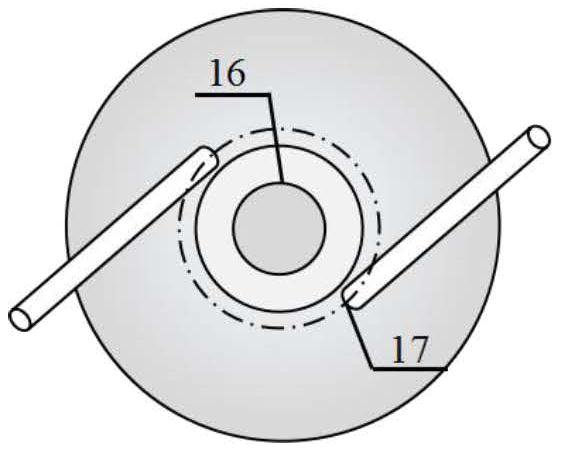

[0023] Such as figure 1 As shown, the high-efficiency pulping equipment before selection suitable for wide particle size flotation of the present invention includes a pulping tank 15, and the pulping tank 15 includes upper and lower parts, the upper part is a columnar structure, and the lower part is a funnel-shaped Inverted cone structure, the top of the pulping barrel 15 is provided with a cylinder cover, and the cylinder cover is respectively provided with a power source and a clean water replenishment port 2, and a dual-channel jet circulation dosing system is installed on both sides of the pulping barrel 15, and the pulping barrel 15 A slurry outlet 4 is provided above the side wall, and two slurry extraction outlets 5 are provided on opposite sides of the columnar structure not higher than the slurry outlet 4 above the side wall. Slurry jets 17 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com