Portable mobile hydrogen making machine based on principle of making hydrogen through methyl alcohol water

A methanol water and hydrogen production machine technology, applied in the field of hydrogen production machines, can solve the problems of high cost of hydrogen movement and storage, hindering hydrogen market production, and difficulty in moving, so as to achieve sustainable development of sources, flexible handling, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

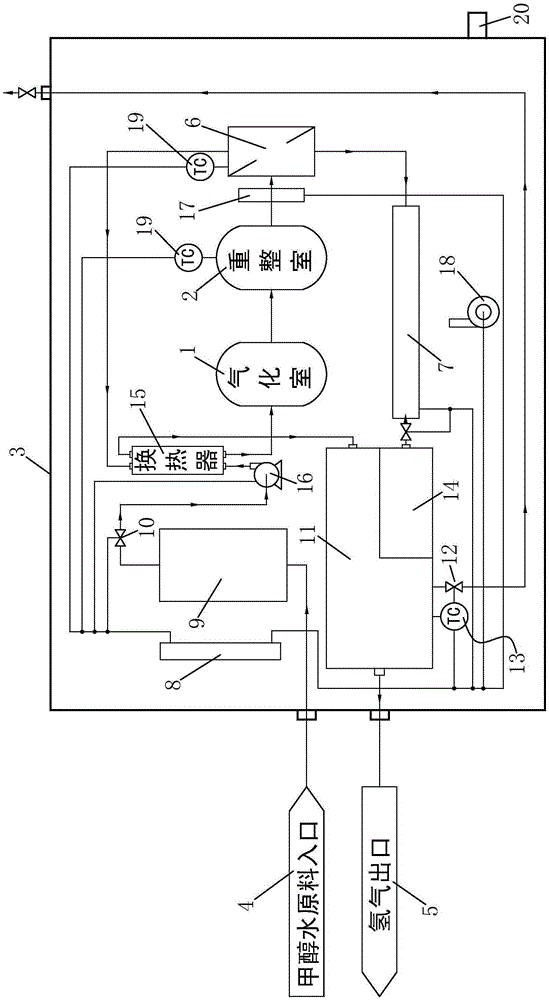

[0024] refer to figure 1 A portable mobile hydrogen generator based on methanol water hydrogen production according to the present invention includes a casing 3, and the casing 3 is provided with a vaporization chamber 1 for vaporizing methanol water and converting methanol water into hydrogen through a catalyst, A reforming chamber 2 for a mixture of methane, carbon monoxide and carbon dioxide, the casing 3 is provided with a methanol water raw material inlet 4 for feeding methanol water, and a hydrogen outlet 5 for outputting hydrogen; the hydrogen generator is also equipped with The hydrogen purification module 6 that allows hydrogen to pass through selectively, the burner 7 that provides the necessary heat for the chemical reaction to the reforming chamber 2, the main control panel 8 used to control the operation of each module in the hydrogen generator, and the methanol water used to store methanol water Storage tank 9, raw material pump 16 for transporting methanol water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com