Combination Feeding Quantitative Scale

A quantitative scale and feeding technology, which is applied in the field of weighing equipment and combined feeding quantitative scale, can solve the problems of narrow range of varieties, lower technical indicators of finished products, and difficulty in adjusting volume, so as to improve weighing efficiency and improve the production environment , the effect of uniform filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific drawings and embodiments.

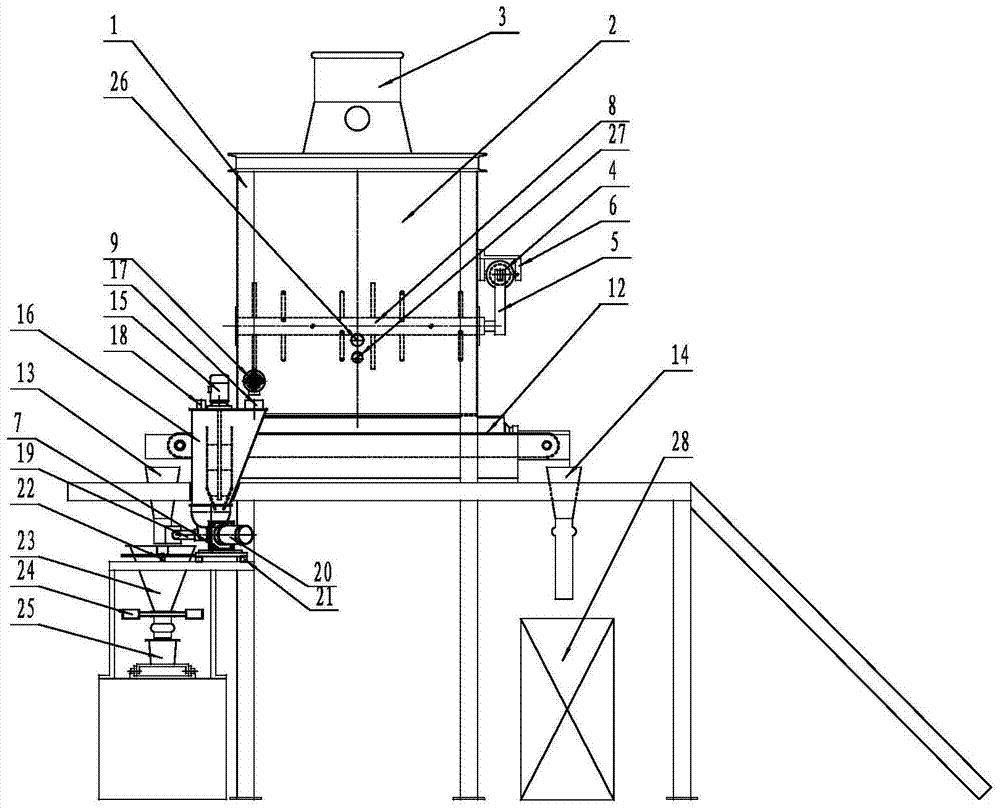

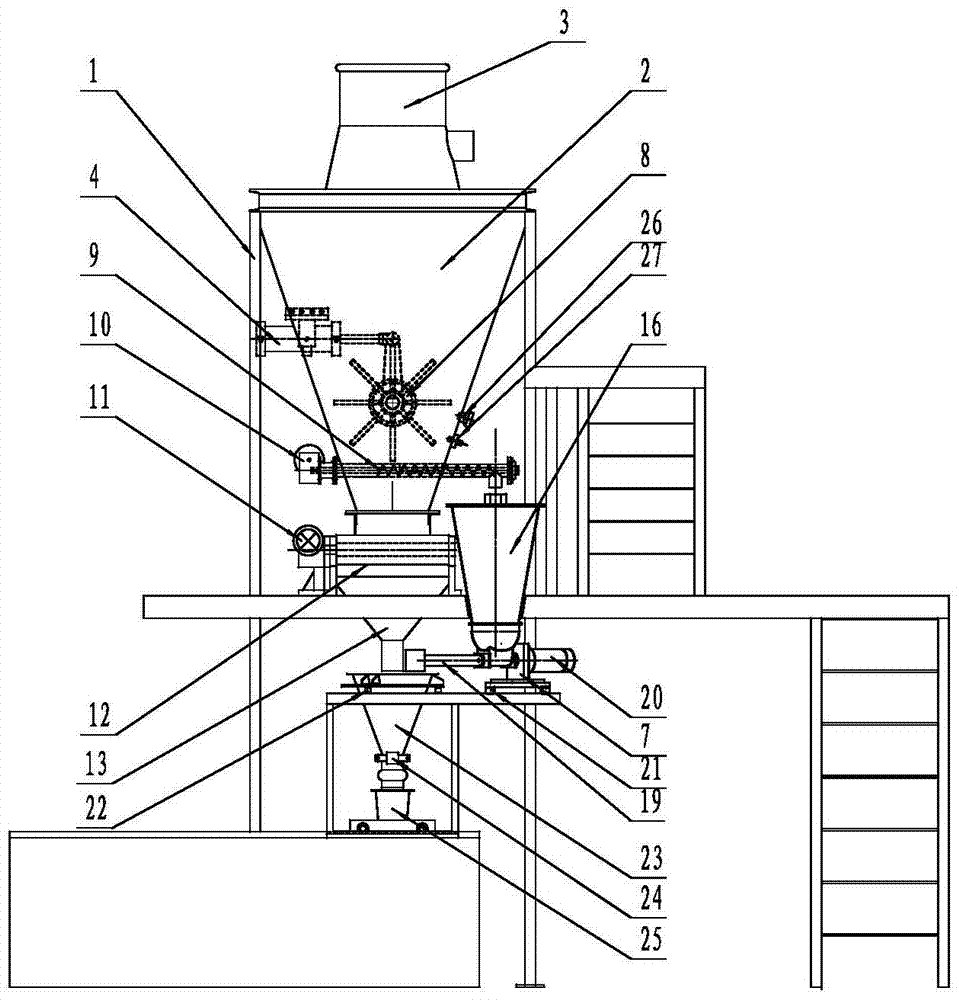

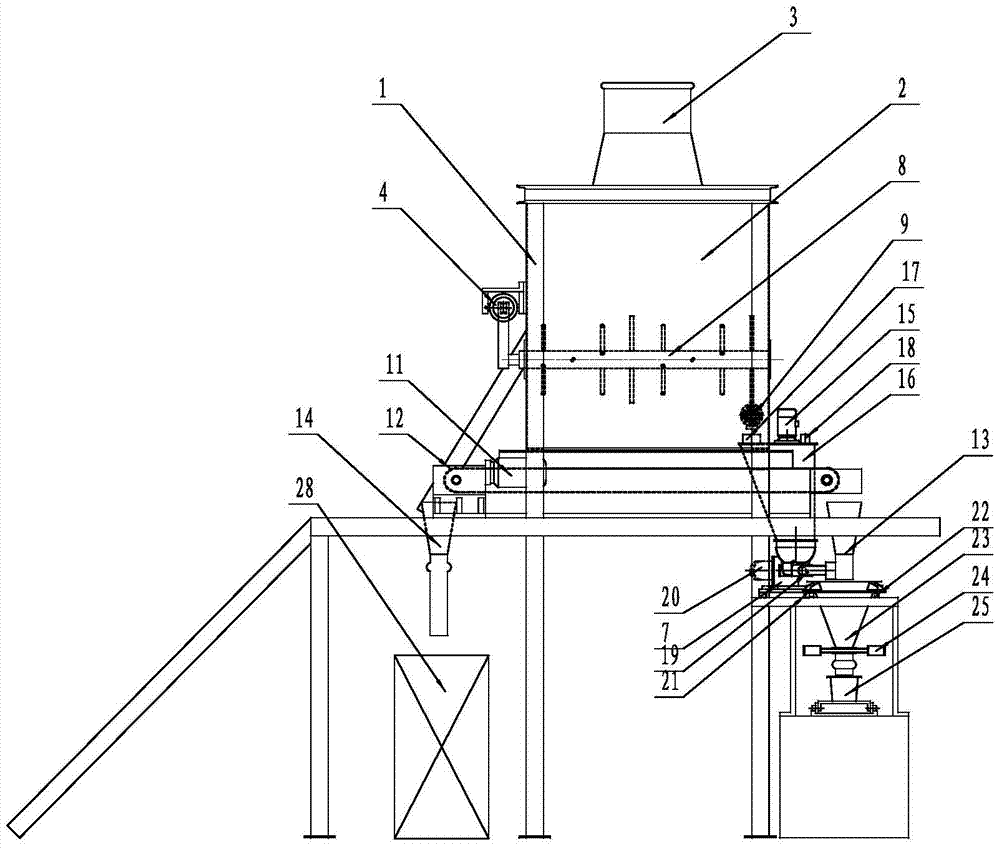

[0036] As shown in the figure: the combined feeding quantitative scale in the embodiment is mainly composed of a frame 1, a large storage hopper 2, an exhaust cover 3, a cylinder 4, a connecting rod 5, a support 6, a feeding support frame 7, and a looser 8 , screw feeder 9, feeding motor 10, belt feeding motor 11, feeding belt 12, belt lower hopper 13, recovery hopper 14, electric looser 15, small storage hopper 16, small storage hopper inlet 17, small Bucket exhaust port 18, screw feeding cylinder 19, screw feeding motor 20, metering sensor 21, feeding sensor 22, metering hopper 23, pneumatic valve 24, movable material box 25, vibration motor 26, material level gauge 27, recycling Box 28 and supporting control cabinet etc. are formed.

[0037] Such as Figure 1~Figure 4 As shown, the rack 1 is used to carry various components of the equipment. The large sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com