Forming method of die forging clamps made of titanium alloy

A technology for die forgings and titanium alloys, which is applied to the forming field of die forgings of titanium alloy clamps, can solve the problems of reduced structure and performance of forgings, reduced die life, waste of metal materials, etc., so as to improve die life, reduce consumption and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

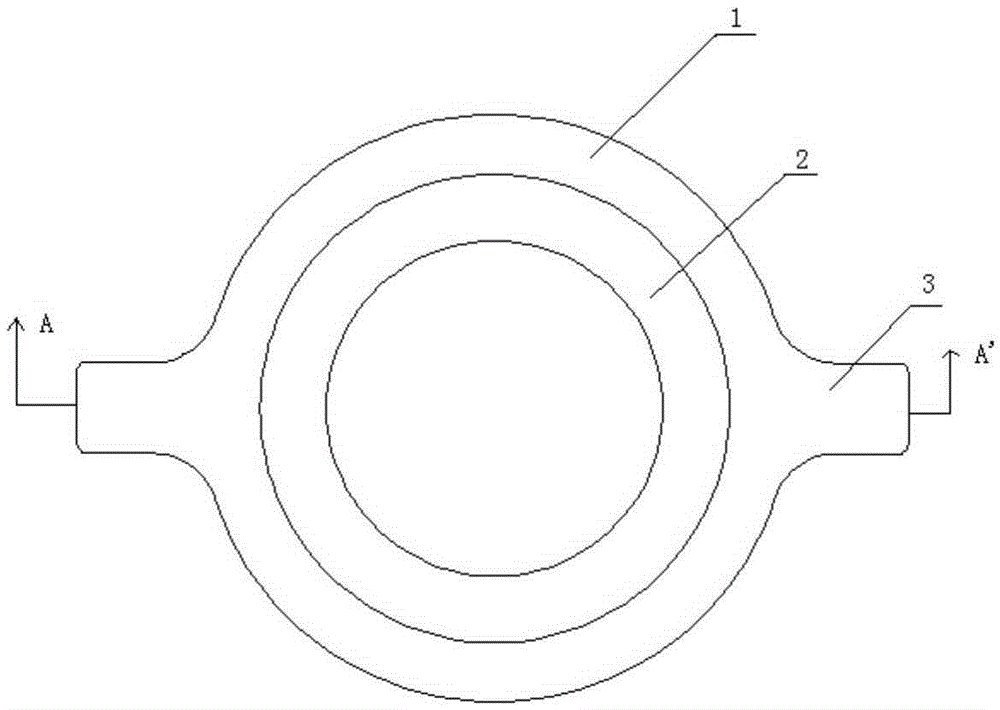

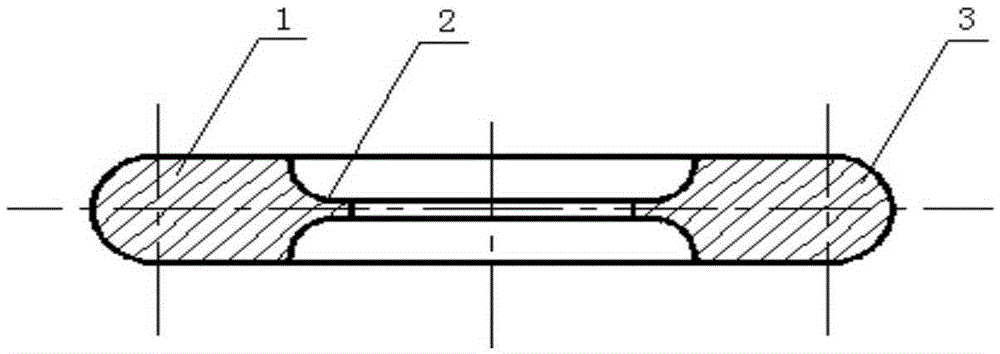

[0024] The clamp type die forging of TC4 titanium alloy material, its forming method comprises the following steps:

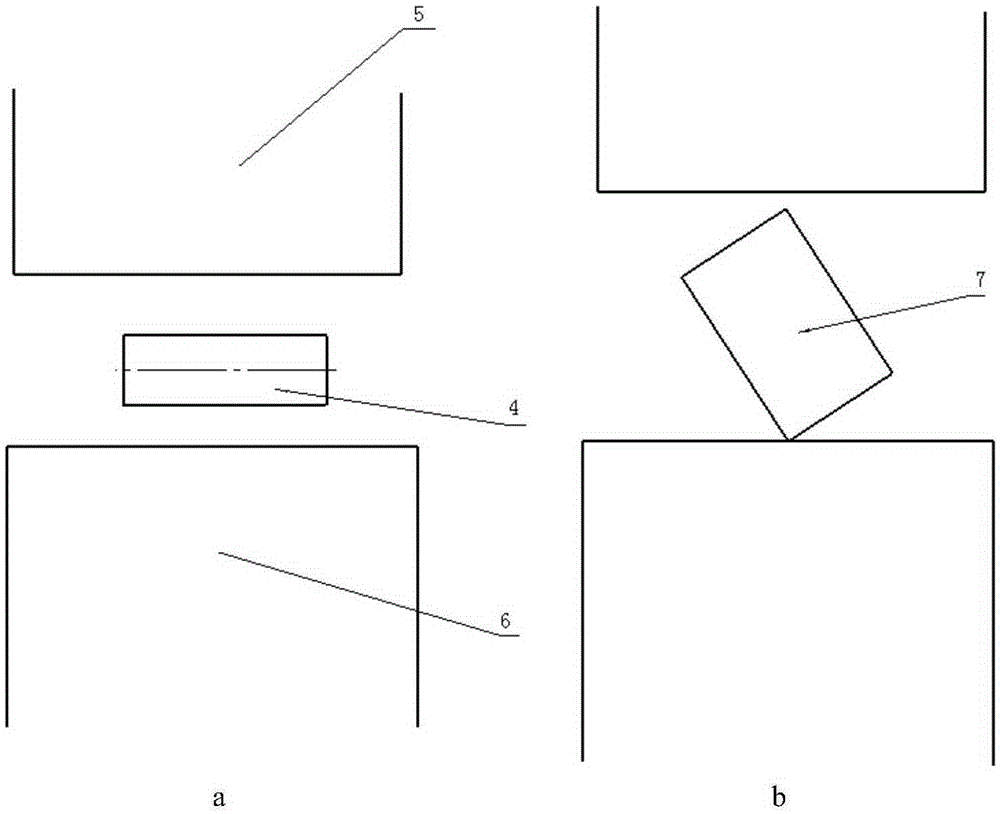

[0025] (1) After heating the titanium alloy bar 4 to 930°C in a heating furnace and keeping it warm for 2 hours, put it on the lower anvil 6 of a 1 ton free forging machine, and flatten the bar under the impact of the upper anvil 5, as image 3 Shown in (a), make flat cuboid blank 7 through repeated hammering again, i.e. height is less than the cuboid of length and width;

[0026] (2) Stand up the flat cuboid blank, then tilt it with the shortest side as the axis, tilt it to an angle of 25° with the horizontal direction, and then forge it into a diamond-shaped blank after repeated hammering, shaping and elongation. The length D1 of the long diagonal line of the blank diamond-shaped surface is 140mm, and the length D2 of the short diagonal line is 88mm, such as image 3 as shown in (b);

[0027] (3) After cleaning the surface defects of the diamond-shaped blan...

Embodiment 2

[0030] The clamp type die forging of TC6 titanium alloy material, its forming method comprises the following steps:

[0031] (1) After heating the titanium alloy bar to 950°C in a heating furnace and holding it for 0.5h, use a 1.5-ton free forging machine to flatten the bar, and then hammer it several times to make a flat cuboid blank, that is a cuboid whose height is smaller than its length and width;

[0032] (2) Stand up the flat cuboid blank, then tilt it with the shortest side as the axis, tilt it to an angle of 15° with the horizontal direction, and then forge it into a diamond-shaped blank after repeated hammering, shaping and elongation. The length D1 of the long diagonal line of the blank diamond-shaped surface is 136mm, and the length D2 of the short diagonal line is 89mm;

[0033] (3) After cleaning the surface defects of the diamond-shaped blank prepared above, heat it to 940°C in a heating furnace and keep it warm for 1 hour. Put the punch on the drain plate, an...

Embodiment 3

[0036] The clamp type die forging of TA15 titanium alloy material, its forming method comprises the following steps:

[0037] (1) After heating the titanium alloy bar to 930°C in a heating furnace and holding it for 1 hour, use a 1-ton free forging machine to flatten the bar, and then hammer it several times to form a flat cuboid blank, that is, the height a cuboid smaller than its length and width;

[0038] (2) Stand up the flat cuboid blank, then tilt it with the shortest side as the axis, tilt it to an angle of 20° with the horizontal direction, and then forge it into a diamond-shaped blank after repeated beating, shaping and elongation. The length D1 of the long diagonal of the blank rhombus is 135mm, and the length D2 of the short diagonal is 87mm;

[0039] (3) After cleaning the surface defects of the diamond-shaped blank prepared above, heat it in a heating furnace to 930°C and keep it warm for 2 hours, place a leaking plate on the lower anvil of the free forging machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com