Conductive heat-dissipating sheet, and electrical parts and electronic devices comprising same

A technology of electronic products and heat sinks, which is applied in the direction of electrical equipment structural parts, electrical components, semiconductor/solid-state device parts, etc., can solve the problem of low thermal conductivity of the adhesive layer, increased elasticity, and reduced adhesion of the adhesive layer and other problems, to achieve the effect of excellent electromagnetic wave shielding performance and excellent thermal diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

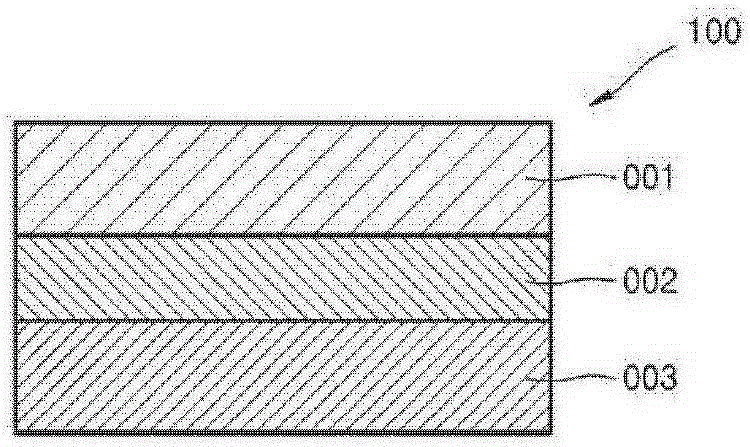

Image

Examples

Embodiment 1

[0121] Example 1: Metal Oxide Thermal Conduction Layer

[0122] (formation of heat conduction layer)

[0123] Electrodeposited copper foil (ILJIN material) with a thickness of 35μm is immersed in 100g / l sulfuric acid for 5 seconds, pickled, and then washed with pure water, followed by a surface commonly called a glossy surface on the copper foil under the following conditions electroplating process of metal oxides. As a result of the electroplating, a blackened metal oxide layer containing Cu, Co and Ni was formed with a thickness of 1 μm on the surface of the copper foil.

[0124] Electrolytic bath composition and plating conditions

[0125] Cu ions (CuSO 4 ·5H 2 O) Concentration: 4g / l

[0126] Co ion (CoSO 4 ·7H 2 O) Concentration: 4g / l

[0127] Ni ions (NiSO 4 ·6H 2 O) Concentration: 5g / l

[0128] Ammonium sulfate ((NH 4 ) 2 SO 4 ) concentration: 15g / l

[0129] Sodium citrate (C 6 h 5 Na 3 o 7 2H 2 O) Concentration: 25g / l

[0130] Electrolyte pH: 5.4

...

Embodiment 2

[0136] Embodiment 2: metal oxide + carbon-based material (CNT) heat conduction layer

[0137] A conductive heat sink was manufactured by the same method as that of Example 1, except that carbon nanotubes at a concentration of 10 g / L were additionally added to the electrolytic bath.

Embodiment 3

[0138] Embodiment 3: metal oxide+carbon-based material (carbon nanofiber) heat conduction layer

[0139] A conductive heat sink was manufactured by the same method as in Example 1, except that carbon nanofibers at a concentration of 10 g / L were additionally added to the electrolytic bath.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com