Composite, manufacturing method of composite, active material for nonaqueous electrolyte battery, and nonaqueous electrolyte battery

A technology of active substances and complexes, applied in the field of complexes, can solve the problems of peeling, easy capacity reduction, weak bonding and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

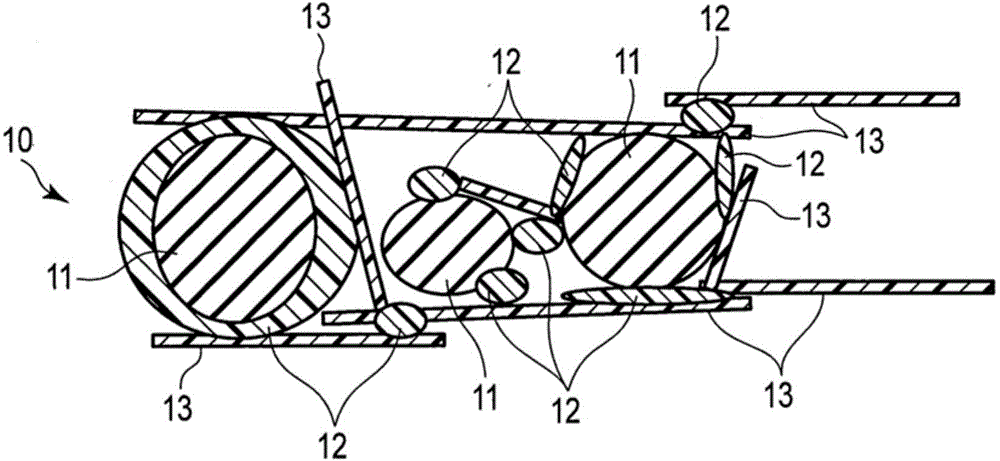

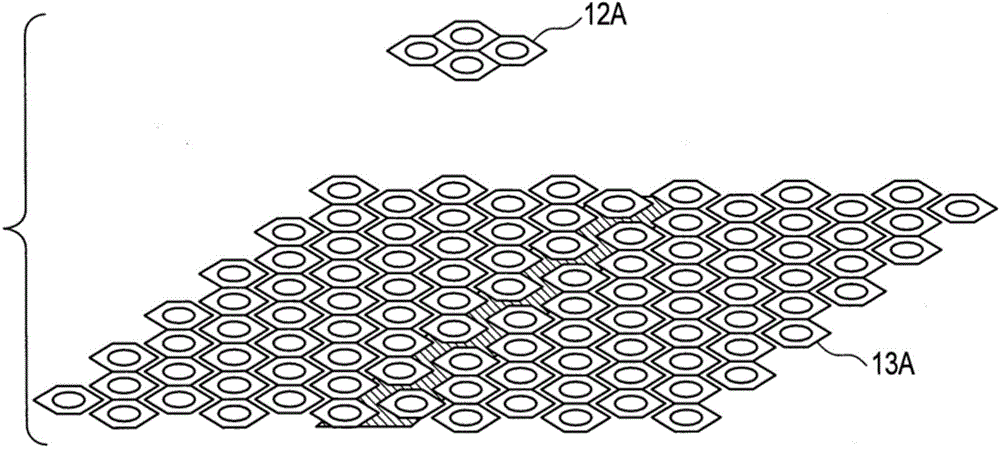

[0050] The first embodiment provides a complex. The composite includes a graphene sheet, a plurality of active material particles, and a carbon layer between the graphene sheet and the active material particles. The graphene sheet includes a monoatomic layer planar graphene sheet or a laminate of ten or less planar graphene sheets. The active material particles contain titanium-niobium composite oxide. The carbon layer contains a carbon material having a π-electron system.

[0051] In the complex of the first embodiment, the graphene sheet can function as a conductive path between a plurality of active material particles.

[0052] On the other hand, due to its size, when used in a non-aqueous electrolyte battery, a graphene sheet has properties such as a solvent for an electrolyte and easy mobility when ions flow. However, the carbon layer contained in the composite of the first embodiment is located between the graphene sheet and the active material particles and contains ...

no. 2 Embodiment approach

[0112] The second embodiment provides a method for producing a composite. The method includes the following steps: a step of preparing a plurality of active material particles; a step of preparing an organic compound; a step of preparing a graphene sheet raw material; putting a plurality of active material particles, an organic compound, and a graphene sheet raw material into water to prepare a dispersed The process of the solution; the process of adjusting the pH of the dispersion solution to less than 2.5; the process of removing water from the dispersion solution to obtain a solid mixture; and the process of heating the solid mixture under an inert atmosphere. The active material particles contain titanium-niobium composite oxide. Organic compounds have multiple hydroxyl groups. The graphene sheet raw material contains a monoatomic layer planar graphene oxide sheet or a laminate of ten or less planar graphene oxide sheets.

[0113] Hereinafter, the manufacturing method of...

no. 3 Embodiment approach

[0150] A third embodiment provides an active material for a non-aqueous electrolyte battery including the complex of the first embodiment.

[0151] As described in the description of the first embodiment, the complex of the first embodiment may be used as a negative electrode of a non-aqueous electrolyte battery, or may be used as a positive electrode.

[0152] The active material for a non-aqueous electrolyte battery of the third embodiment may contain only the composite of the first embodiment or may further contain active material particles of the composite of the first embodiment when used as a negative electrode active material. Other active substances that contain different active substances. Examples of such other active materials include lithium-titanium composite oxides (Li 4 Ti 5 o 12 etc.), titanium oxides with anatase, rutile or monoclinic β-type structures (a-TiO 2 , r-TiO 2 or TiO 2 (B) etc.) and iron complex sulfides (FeS, FeS 2 Wait).

[0153] The activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com