High-pressure, oxygen-free, yield-increasing and plug-release gas injection device of CBM (Coal Bed Methane) well and using method of high-pressure, oxygen-free, yield-increasing and plug-release gas injection device

A technology for coalbed methane wells and coalbed methane, which is applied in the field of high-pressure anaerobic production increase and blockage removal gas injection devices for coalbed methane wells, which can solve problems such as insufficient driving force and difficult desorption, and achieve simple operation, increased production, improved production efficiency and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

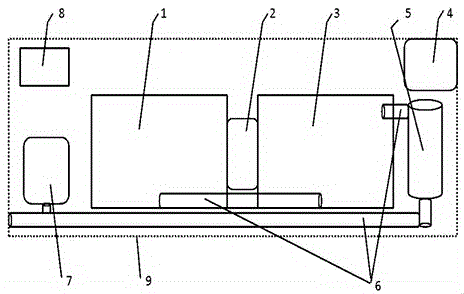

[0022] Example 1: Connect the casing mouth of the coalbed methane well to the gas pipeline 6 through a high-temperature and high-pressure flexible connection, open the gas injection gate of the casing to vent, connect one end of the high-temperature and high-pressure hose to the casing and the other to the gas pipeline 6, and the internal combustion engine 1 and The control cabinet 8 is connected to each other, and the automatic dosing device 7 is started, and the filling amount of surfactant and corrosion inhibitor is calculated according to the liquid output, well depth and gas production of the coalbed methane well and the actual situation of downhole management. After the dosing device completes the filling Automatically shuts off. After the dosing is completed, under the condition that the injection pressure is lower than the rupture pressure of the coalbed methane reservoir, the internal combustion engine 1 is started through the control cabinet 8 and the compressor 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com