Device and method of adjustment and control of pressure of carbonization chamber in coking process of large-size coke oven

A technology of control device and pressure regulation, applied in furnace safety device, coke oven, petroleum industry, etc., can solve the problems of increasing labor cost, large impact of pushing coke, reducing production efficiency, etc. The effect of smoke and fire, reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

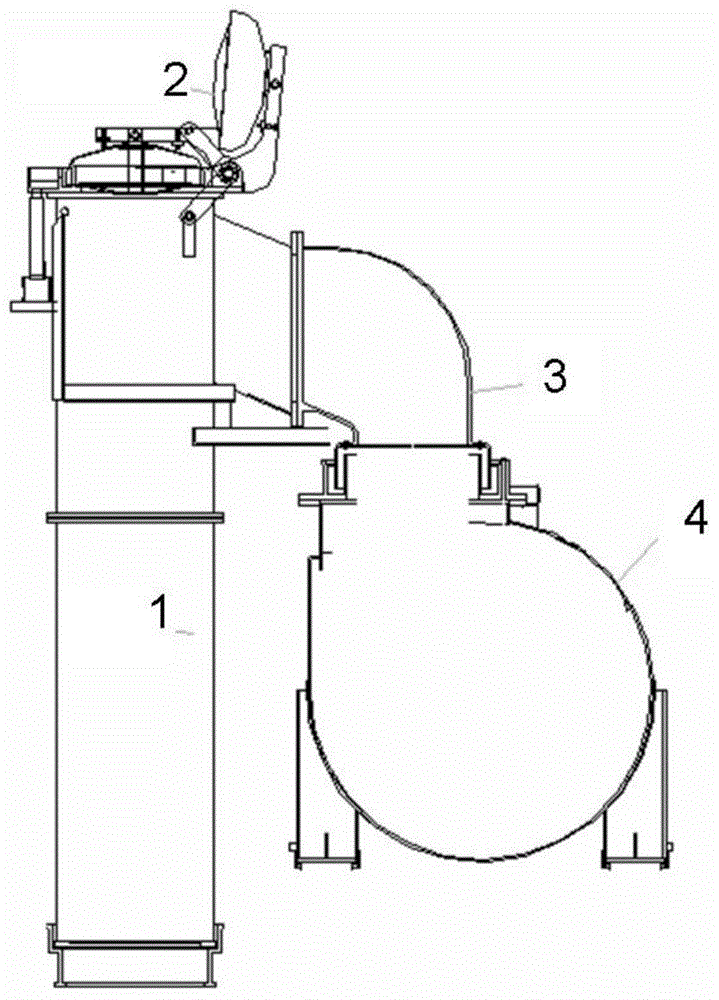

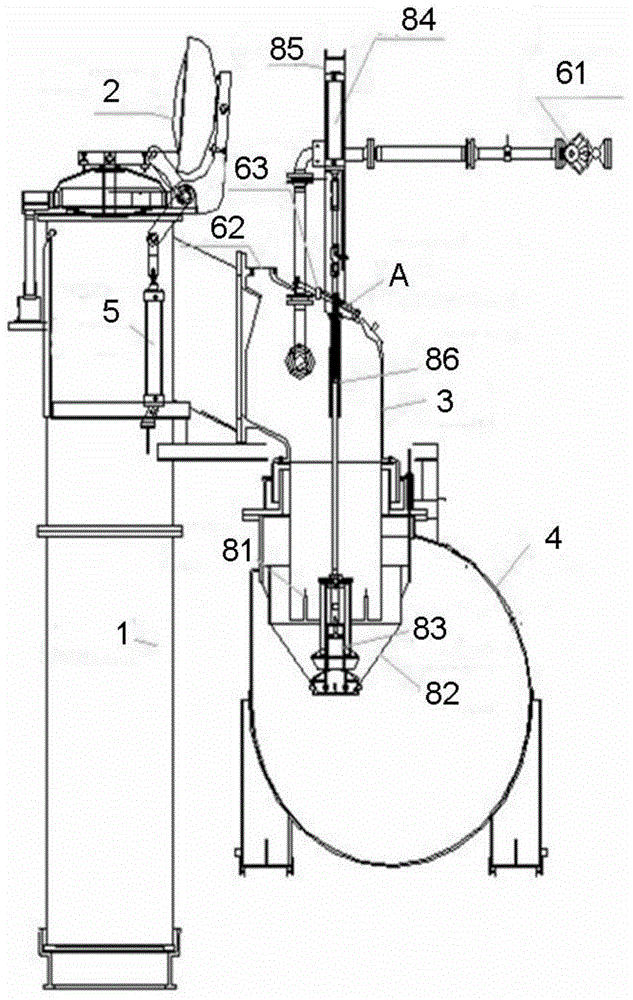

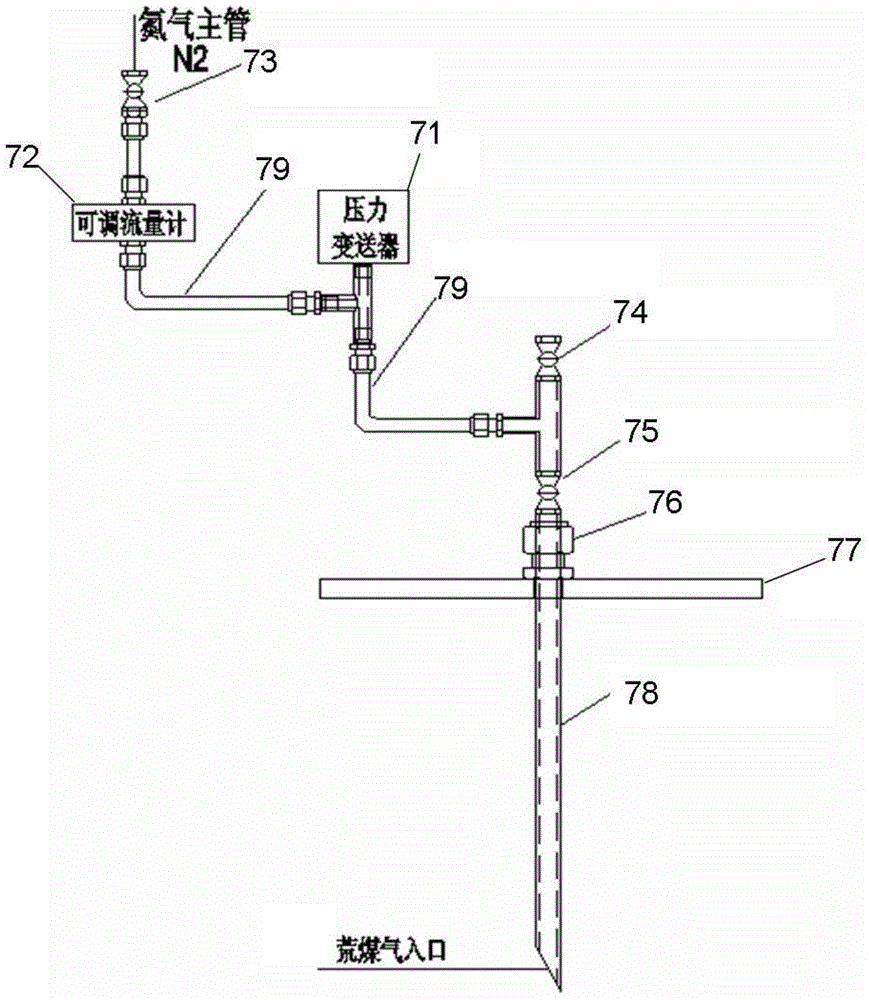

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below through specific embodiments and accompanying drawings.

[0043] During the coking process of the coke oven, the change of coking time and heating system makes the gas production fluctuate obviously; the composition of coal, the change of coal loading and the actual coking time will also affect the change of the gas collector pressure. The pressure control of the carbonization chamber is the control of the whole process of coking. According to the coking time, the present invention sets the set value in several stages, such as nine stages. Follow the rule that the coking chamber pressure setting value increases from small to large from the initial stage of coking to the end stage of coking.

[0044] Pressure regulation during coking of the coke oven is to use the pressure value in the model as the target setting value, and automatically adjust the pressure of the carbonization chamber during the coking process to adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com