Inorganic waterproof ageing-resistant coating and preparation method thereof

An anti-aging coating, inorganic technology, applied in the coating and other directions, can solve the problems of large film shrinkage, limited application and promotion, poor water resistance, etc., and achieve the effect of increasing the toughness of the coating film, good toughness, and not easy to absorb ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

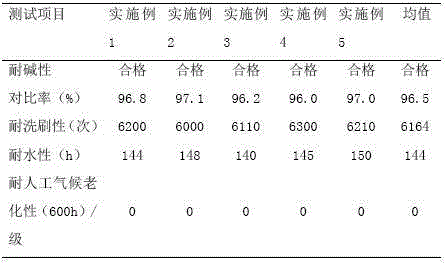

Examples

Embodiment 1

[0033] An inorganic waterproof and aging-resistant coating, which is composed of the following raw materials in parts by weight: silica sol: 60; sepiolite: 10; silane-modified mica: 5; inorganic mineral pigments: 8; silane-modified heavy calcium powder: 6 ; Silane-modified zinc oxide: 4; Silane-modified wollastonite: 4; Water-based defoamer: 0.5; Magnesium aluminum silicate: 0.6.

[0034] The preparation method of the above-mentioned inorganic waterproof and aging-resistant coating can be implemented according to the following steps.

[0035] (1) Add sepiolite, inorganic mineral pigments and fillers (silane-modified mica, silane-modified heavy calcium powder, silane-modified zinc oxide and silane-modified wollastonite) into the silica sol for soaking, soaking time for 3 hours, and then disperse for 10 minutes under the condition of 1500r / min.

[0036] (2) Disperse at a high speed of 3000r / min until the fineness is less than 50μm, and control the system temperature below 50°C....

Embodiment 2

[0044] An inorganic waterproof and aging-resistant coating, which is composed of the following raw materials in parts by weight: silica sol: 55; sepiolite: 10; silane-modified mica: 8; inorganic mineral pigments: 6; silane-modified heavy calcium powder: 4 ; Silane-modified wollastonite 6; Water-based defoamer: 0.2; Magnesium aluminum silicate: 1.

[0045] The preparation method of the above-mentioned inorganic waterproof and aging-resistant coating can be implemented according to the following steps.

[0046] (1) Add sepiolite, inorganic mineral pigments and fillers (silane-modified mica, silane-modified heavy calcium powder and silane-modified wollastonite) into the silica sol and soak for 3 hours, then soak at 1500r Disperse for 10min under the condition of / min.

[0047] (2) Disperse at a high speed of 3000r / min until the fineness is less than 50μm, and control the system temperature below 50°C.

[0048] (3) Reduce the stirring speed to 800r / min, add water-based defoamer an...

Embodiment 3

[0051] An inorganic waterproof and aging-resistant coating, which is composed of the following raw materials in parts by weight: silica sol: 50; sepiolite: 10; silane-modified mica: 4; inorganic mineral pigment: 6; aluminum hydroxide: 5; Foaming agent: 0.3; magnesium aluminum silicate: 0.8.

[0052] The preparation method of the above-mentioned inorganic waterproof and aging-resistant coating can be implemented according to the following steps.

[0053] (1) Add sepiolite, inorganic mineral pigments and fillers (silane-modified mica and aluminum hydroxide) into the silica sol and soak them for 3 hours, then disperse at 1500r / min for 10 minutes.

[0054] (2) Disperse at a high speed of 3000r / min until the fineness is less than 50μm, and control the system temperature below 50°C.

[0055] (3) Reduce the stirring speed to 800r / min, add water-based defoamer and magnesium aluminum silicate according to the metered amount, and obtain the target product after uniform dispersion.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com