Planar solid oxide fuel cell stack temperature distribution estimation method

A technology of fuel cell stacks and solid oxides, which is applied in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., and can solve problems such as jitter and system controller output jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

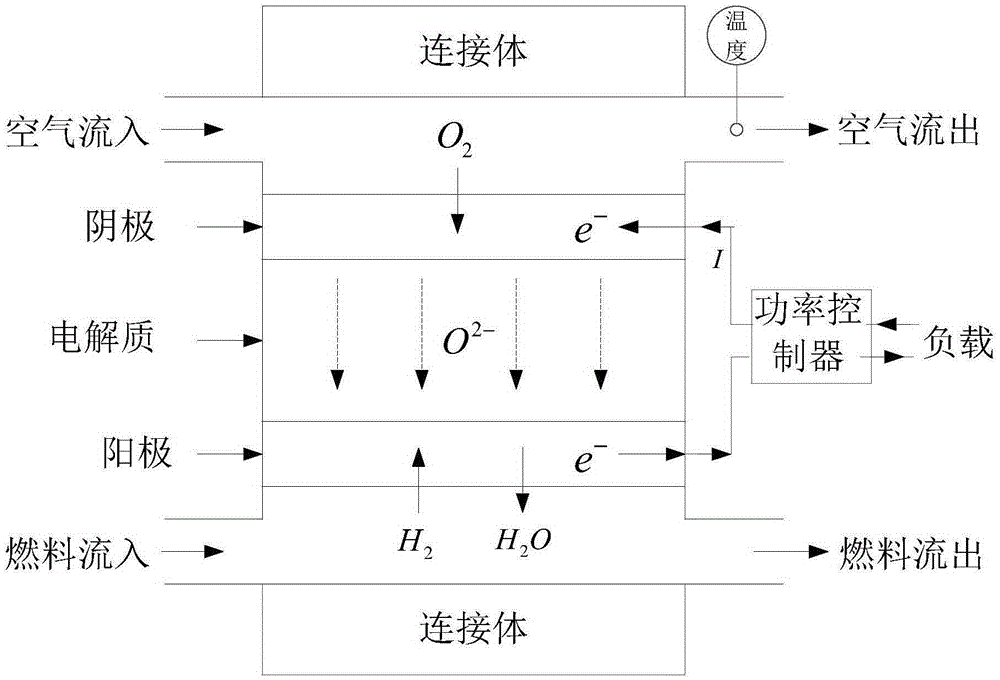

[0073] Such as figure 1 As shown, a method for estimating the temperature distribution of a flat solid oxide fuel cell stack includes the following steps:

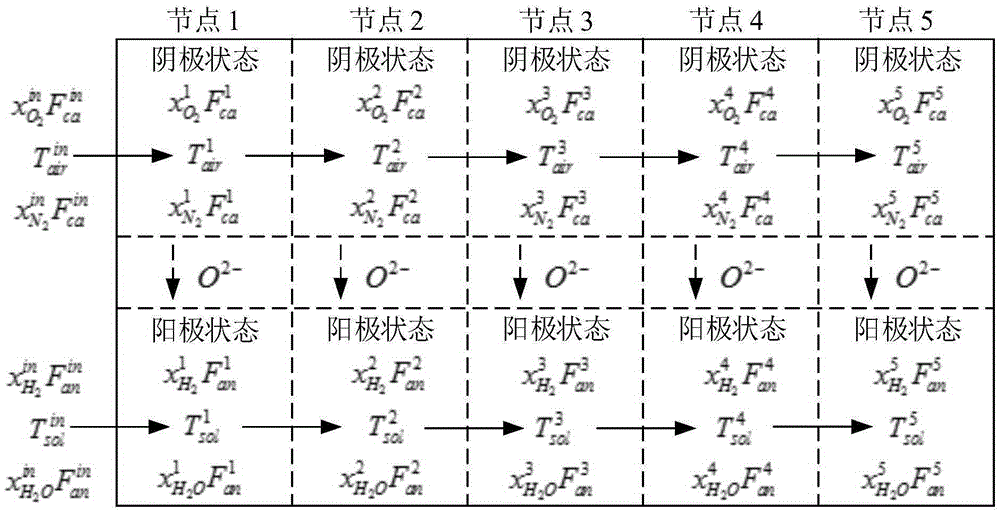

[0074] S1. Establish a nonlinear stack temperature model according to the law of mass conservation and energy conservation, and perform finite element processing on the stack temperature model;

[0075] S2. Near the stable operating point, linearize the stack temperature model described in step S1 to obtain a linear stack temperature model;

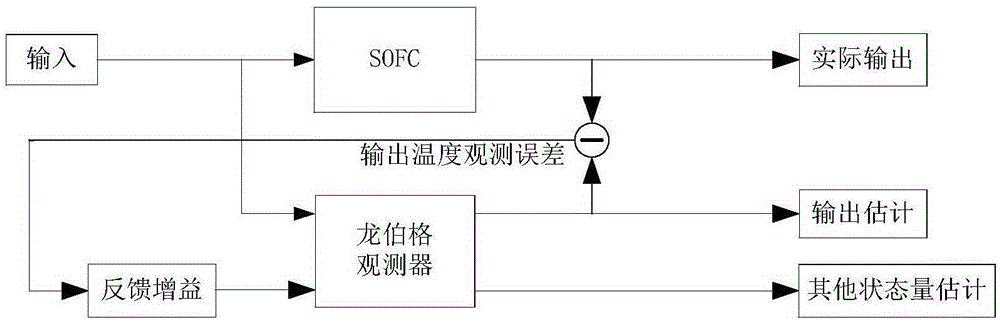

[0076] S3. Based on the above-mentioned linear stack temperature model, a Lomberg observer for observing the stack temperature is designed;

[0077] S4. The actual output of the solid oxide fuel cell is used as the input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com