Display method of F/M heat resistant steel welded joint heat affected zone original austenite grain boundary

A technology of austenite grain boundaries and welded joints is applied in the field of metallographic preparation, which can solve the problems of difficulty in displaying the prior austenite grain boundaries of F/M heat-resistant steel, and achieve high repeatability, good stability and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

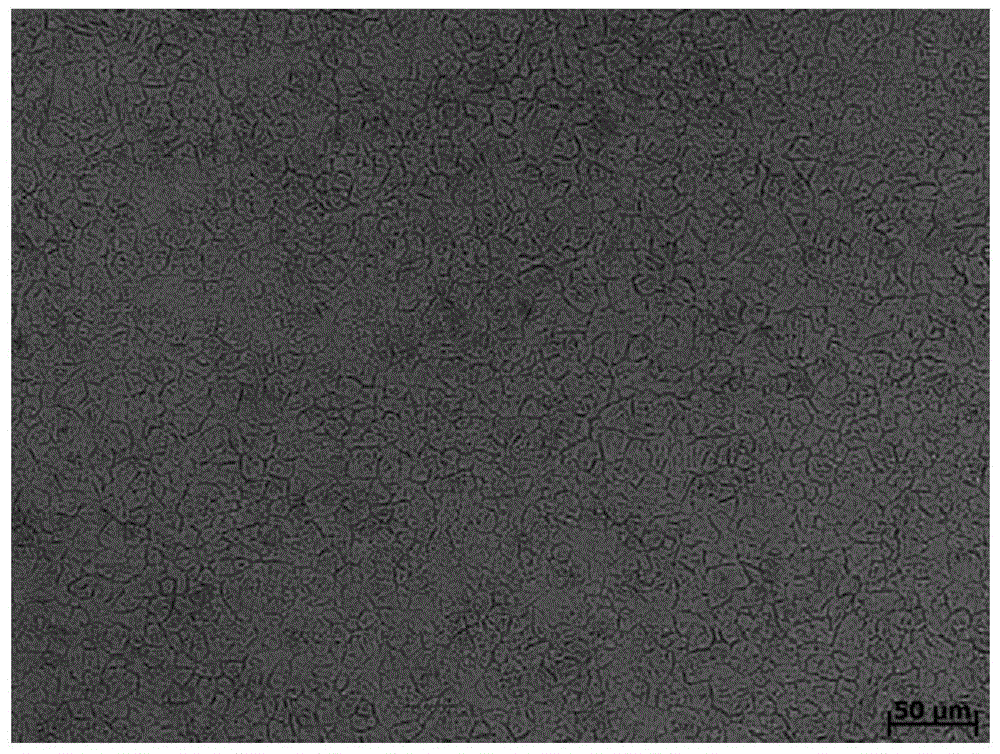

[0028] This example shows the grain boundaries of prior austenite in the uncoarser region of 9Cr2WVTa steel.

[0029] The chemical composition of 9Cr2WVTa steel is (wt.%): C0.14%, Cr9.04%, W1.99%, V0.25%, Ta0.17%, Mn0.45%, and the balance is Fe. On the Gleeble1500 thermal simulation test machine, the welding thermal cycle with the peak temperature of 1315 ° C and 1315 ° C was used to obtain the unrefined coarse-grained zone structure.

[0030] 1. First cut the sample of the heat-affected zone of the welded joint that has not become coarse grained, and place one of the planes of the sample on 240#, 400#, 600#, 800#, 1000#, 2000# metallographic sandpaper from coarse to Grind finely. Before changing the sandpaper each time, ensure that there is no scratch on the surface of the sample perpendicular to the polishing direction. After changing the sandpaper, rotate the sample 90° for the next polishing until the scratch left by the previous one is removed. After grinding, use navy w...

Embodiment 2

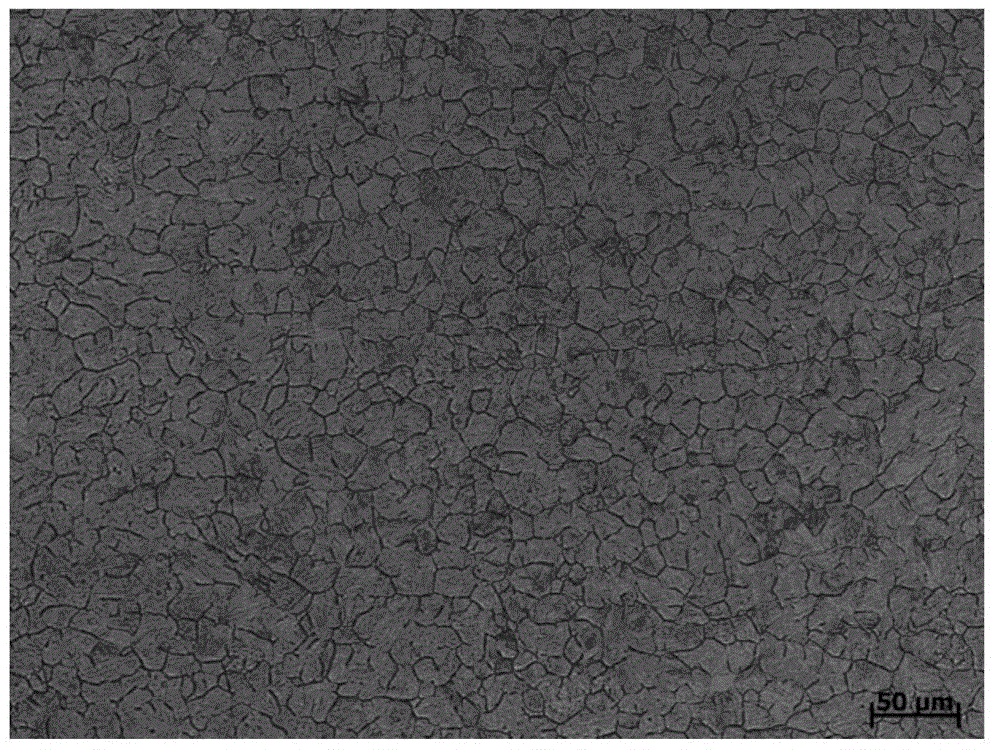

[0034] This example shows the grain boundaries of the original austenite in the supercritical coarse-grained region of 9Cr2WVTa steel.

[0035] The chemical composition of 9Cr2WVTa steel is (wt.%): C0.14%, Cr9.04%, W1.99%, V0.25%, Ta0.17%, Mn0.45%, and the balance is Fe. The supercritical coarse-grained zone microstructure was obtained through welding heat cycles with peak temperatures of 1315°C and 1100°C on a Gleeble1500 thermal simulator.

[0036] 1. First, cut the sample of the heat-affected zone of the welded joint over the critical coarse-grained zone, and place one of the planes of the sample on 240#, 400#, 600#, 800#, 1000#, 2000# metallographic sandpaper from coarse to Grind finely. Before changing the sandpaper each time, ensure that there is no scratch on the surface of the sample perpendicular to the polishing direction. After changing the sandpaper, rotate the sample 90° for the next polishing until the scratch left by the previous one is removed. After grinding,...

Embodiment 3

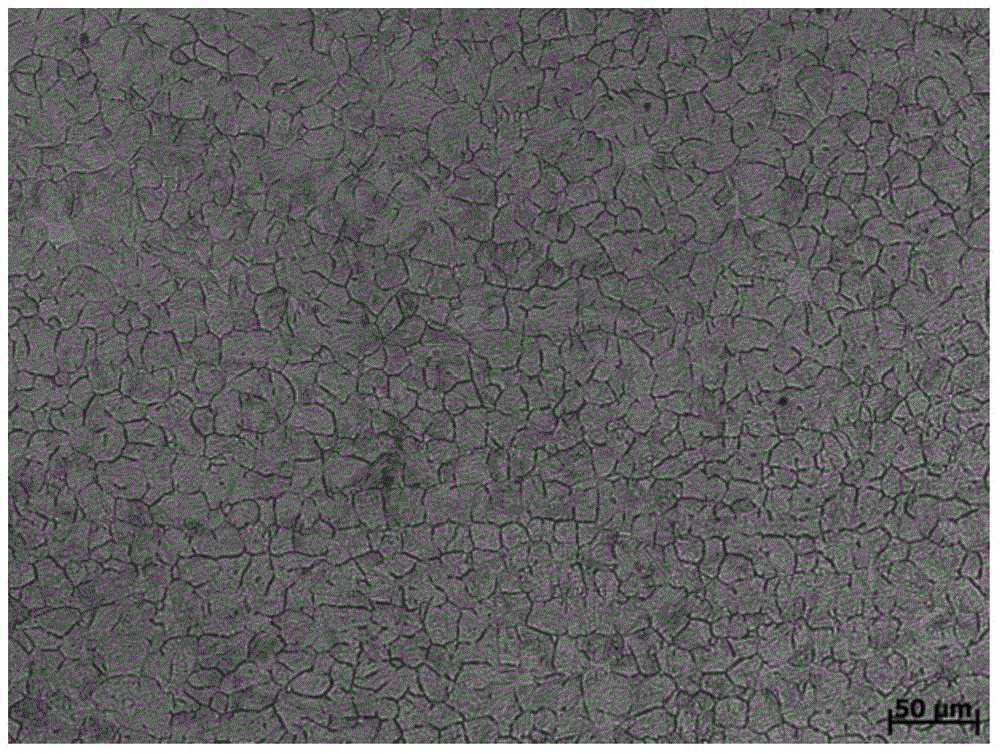

[0040] This example shows the grain boundaries of prior austenite in the critical coarse grain region of 9Cr2WVTa steel.

[0041] The chemical composition of 9Cr2WVTa steel is (wt.%): C0.14%, Cr9.04%, W1.99%, V0.25%, Ta0.17%, Mn0.45%, and the rest is Fe. The critical coarse-grained zone microstructure was obtained through welding heat cycles with peak temperatures of 1315°C and 970°C on a Gleeble 1500 thermal simulator.

[0042] 1. First cut the sample of the critical coarse-grained zone in the heat-affected zone of the welded joint, and place one of the planes of the sample on 240#, 400#, 600#, 800#, 1000#, 2000# metallographic sandpaper from coarse to fine For polishing, ensure that there are no scratches on the surface of the sample perpendicular to the polishing direction before changing the sandpaper each time. After changing the sandpaper, rotate the sample 90° for the next polishing until the scratches left by the previous one are removed. After grinding, use navy wool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com