Supercritical circulating fluid bed boiler water wall having high flow stability under low load

A circulating fluidized bed and water-cooled wall technology, which is applied to boiler water pipes, fluidized bed combustion equipment, and fuel burning in a molten state, can solve the problems of decreased flow stability, increased water-cooled wall area and furnace height, etc., to prevent The effect of negative feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

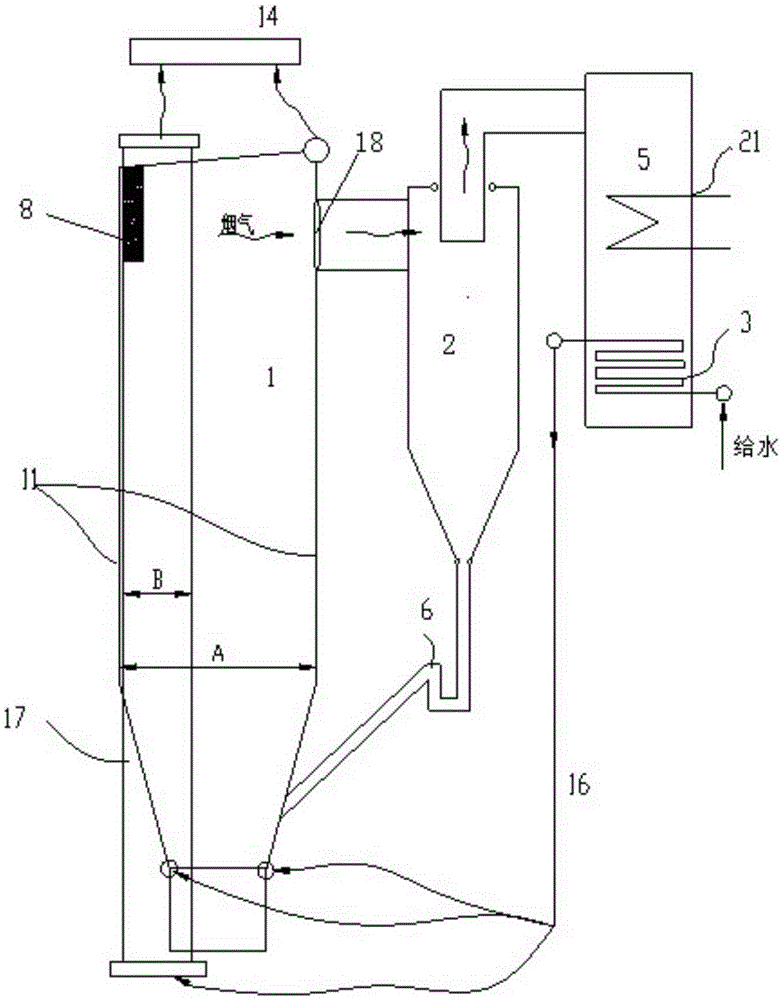

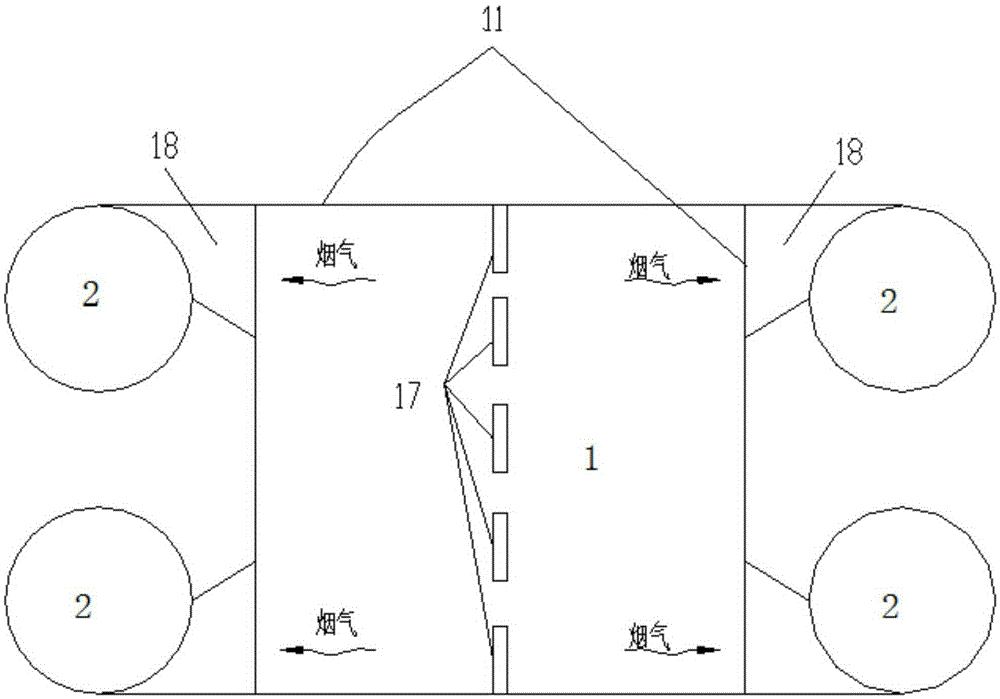

[0038] The present invention will be further described below with reference to specific embodiments and accompanying drawings.

[0039] The method for realizing low mass flow rate in the water wall of supercritical CFB boiler, the steps are:

[0040] First, according to the steam flow (T) of the CFB boiler and the fuel, the flue gas flow (Q) generated by combustion is calculated, and then the cross-sectional area of the furnace is obtained from the flue gas flow and the flue gas flow rate in the furnace: the main element carbon in the fuel (C) The combustion of hydrogen (H) sulfur (S) emits heat and also generates flue gas. The amount of heat released and the amount of flue gas generated can be known from known chemical knowledge. The flue gas flow Q can be calculated according to the balance of the heat that the steam needs to absorb and the heat generated by the combustion of the fuel. The choice of flue gas flow rate in the furnace is generally V=4-6m / s. Q / V=S, S is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com