Large long cone-shaped horn cylinder part extruding forming method

A technology of extrusion forming and horn, which is applied to other manufacturing equipment/tools, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient punch strength and breakage, and achieve the effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawings and examples.

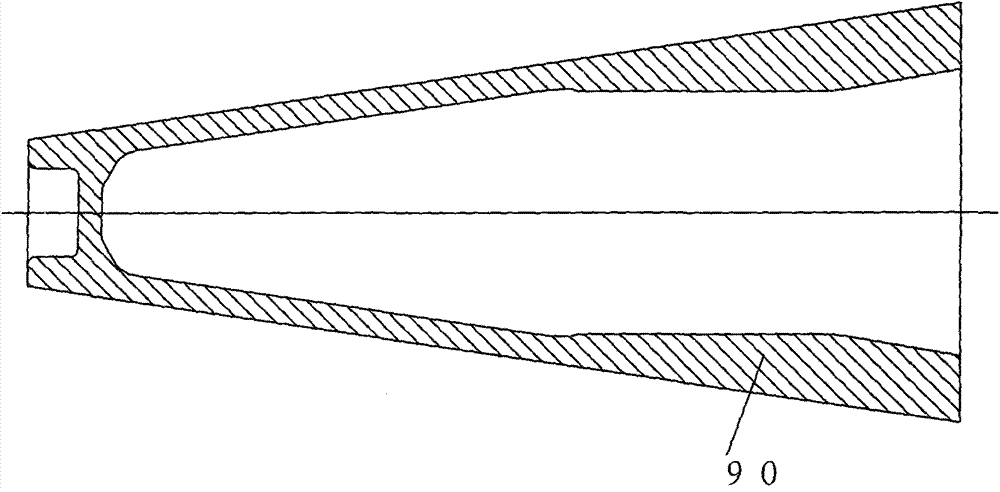

[0044] A method for extrusion forming of large-scale long tapered trumpet parts, sawing and blanking --- upsetting pre-forming --- primary extrusion of hemispherical bottom straight wall tube --- secondary flaring, shaping, extrusion cone barrel, as follows:

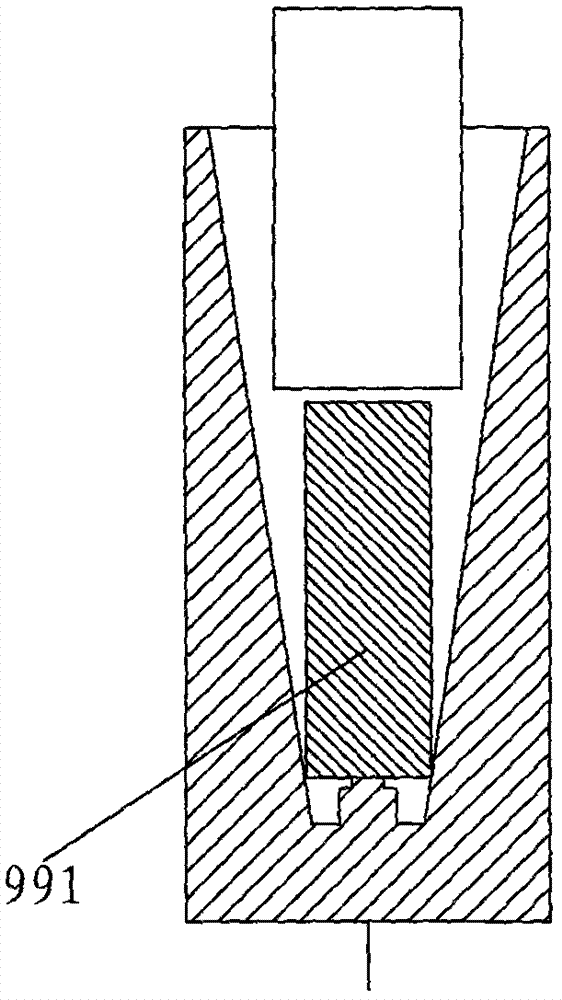

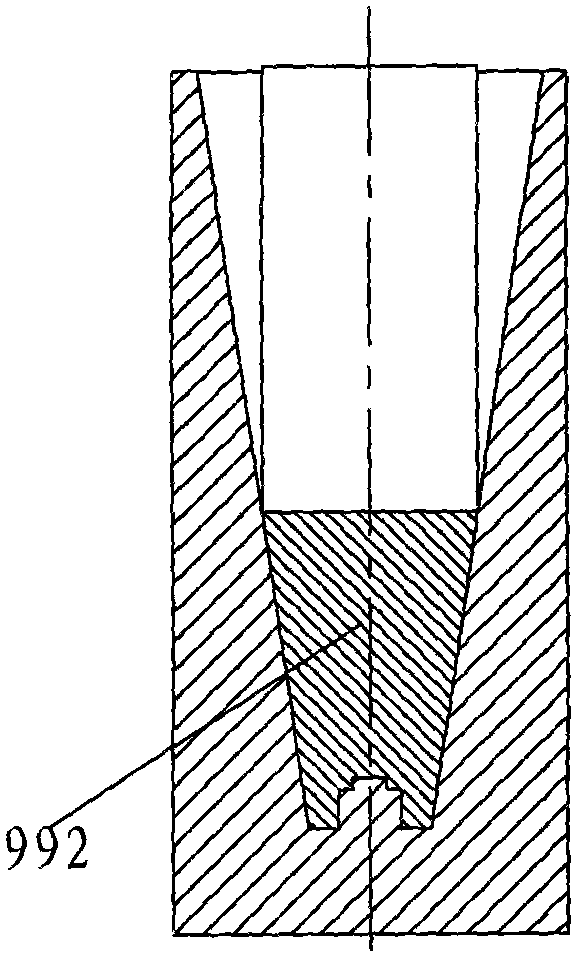

[0045] (1), sawing blanking---upsetting preforming, such as Figure 6 , Figure 7 As shown, using isothermal extrusion of magnesium alloy or aluminum alloy, the heating temperature of the blank 99 is 350°-400°, the heating temperature of the upsetting die 401 is 420°, and the upsetting die 401 is put into the upsetting die 401 to use the upsetting punch punch 31 Carry out upsetting, the mold cavity 402 of upsetting die 401 and long taper trumpet part 9 (as Figure 14 Shown) the shape of the upper half is consistent, forming an upsetting blank 995 (such as Figure 7 shown);

[0046] (2) Extrude the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com