Bimetal compound high-toughness, high-boron and high-speed steel hammer and preparing method thereof

A high-toughness, bimetallic technology, applied in the field of wear-resistant metal materials, can solve the problems of high production cost, undurable hammer head, frequent replacement of hammer heads, etc., achieve convenient heating, increase flushing time, and facilitate metallurgical bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

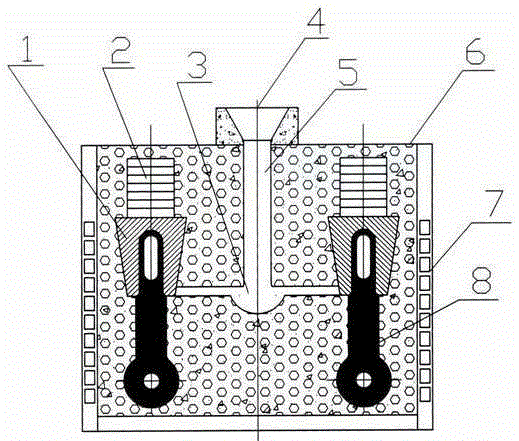

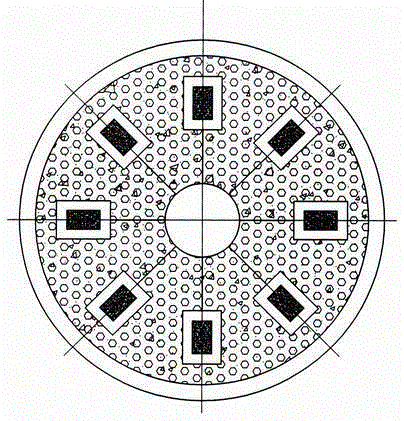

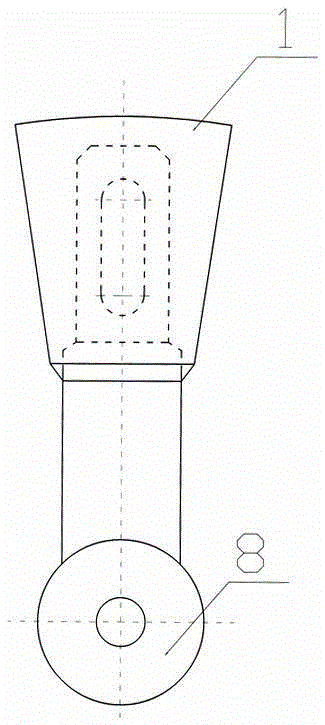

Method used

Image

Examples

Embodiment 1

[0066] (1) Material composition design of hammer head and hammer handle:

[0067] ①The chemical composition and mass percentage of the high-boron high-speed steel hammer head are: 0.45%C, 0.9%B, 3.8%Cr, 0.5%Si, 3.8%Mn, 0.8%Mo, 1.5%W, 0.5%V, 0.4% Cu, 0.40%Ti, 0.05%Nb, 0.10%Ca, 0.06%Ce, 0.05%Y, 0.04%N, 0.12%Mg, 0.06Ba, 0.04%K, S<0.03%, P<0.04%, the balance is Fe and unavoidable impurity elements.

[0068] ② The chemical composition and mass percentage of the hammer handle material are; the chemical composition and mass fraction of low-carbon bainite steel are: 0.20% C, 2.50% Mn, 1.00% Si, 0.02N, 0.005% B, 0.03% Nb, 0.010% Ba, 0.05% ReSiMg, <0.03% S, <0.04% P, the balance is Fe and unavoidable impurity elements.

[0069] The manufacturing process steps are:

[0070] (1) Manufacture of boron agent and metamorphic inoculant:

[0071] Crush ferrovanadium, ferrotitanium, ferroniobium, potassium oxide, silicon-calcium-barium alloy, and nitrogen-containing ferrochrome into 60-100 m...

Embodiment 2

[0092] The present invention can be realized through the design and technical scheme of following basic chemical composition, comprises the following steps:

[0093] (1) Material composition design of high boron high speed steel hammer head and hammer handle:

[0094] ①The chemical composition and mass percentage of the high boron high speed steel hammerhead material are: 0.6%C, 1.5%B, 4.5%Cr, 0.8%Si, 4.5%Mn, 2.0%Mo, 2.5%W, 1.0%V, 0.90% Cu, 0.80%Ti, 0.15%Nb, 0.15%Ca, 0.20%Ce, 0.15%Y, 0.10%N, 0.20%Mg, 0.08Ba, 0.10K, S<0.03%, P<0.04%, the balance is Fe and unavoidable impurity elements.

[0095] ② The material of the hammer handle is directly made of low alloy steel.

[0096] The manufacturing process steps are:

[0097] (1) Manufacture of boron agent and metamorphic inoculant:

[0098] Crush ferrovanadium, ferrotitanium, ferroniobium, potassium oxide, silicon-calcium-barium alloy, and nitrogen-containing ferrochrome into 60-100 mesh powders, and crush 60-100 mesh BC, BN, B ...

Embodiment 3

[0116] The present invention can be realized through the design and technical scheme of following basic chemical composition, comprises the following steps:

[0117] (1) Material composition design of high boron high speed steel hammer head and hammer handle:

[0118] ①The chemical composition and mass percentage of the hammerhead material are: 0.8%C, 2.4%B, 5.2%Cr, 1.0%Si, 5.5%Mn, 3.0%Mo, 3.5%W, 1.5%V, 1.4%Cu, 1.0% Ti, 0.3%Nb, 0.25%Ca, 0.3%Ce, 0.2%Y, 0.18%N, 0.25%Mg, 0.15Ba, 0.13%K, S<0.03%, P<0.04%, the balance is Fe and unavoidable impurity elements.

[0119] ② The chemical composition and mass percentage of the hammer handle material are; the chemical composition and mass fraction of low-carbon bainite steel are: 0.35% C, 3.00% Mn, 1.70% Si, 0.08N, 0.010% B, 0.07% Nb, 0.020% Ba, 0.25% ReSiMg, <0.03% S, <0.04% P, the balance is Fe and unavoidable impurity elements.

[0120] The manufacturing process steps are:

[0121] (1) Manufacture of boron agent and metamorphic inoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com