Emulsion special for composite rock slices and preparation method of emulsion

A technology for composite rock chips and emulsions, which is applied in the field of special emulsions for composite rock chips and their preparation, can solve the problems that it is difficult to meet the use requirements of composite rock chips, easily broken during storage and transportation, and has poor water resistance and solvent resistance. The effect of tack back, strong flexibility, good water resistance and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of special emulsion for composite rock slice of the present invention comprises the following steps:

[0024] a: Preparation of base liquid A: Add 30-70% of total water and 0.1-0.9% of surfactant to the reactor with agitator, condenser, and constant-flow pump feeding device, and heat up to the temperature in the kettle Reach 80-85°C;

[0025] b: Preparation of monomer solution B: mix styrene, butyl acrylate, methyl methacrylate, methacrylamide, acrylic acid, surfactant 0.9-1.1%, and water 10-50% at normal temperature and pressure Mix into a uniform solution and stir for 10-30 minutes for later use;

[0026] c: Preparation of initiator solution C: add the initiator to the remaining water, stir to dissolve;

[0027] d: When the temperature in the kettle reaches 80°C-85°C, add 1-5% monomer solution B and 10-30% initiator solution C to the reactor. Add the remaining monomer solution B and initiator solution C dropwise into the container, and the dr...

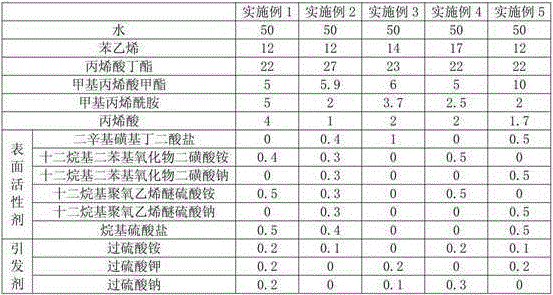

Embodiment 1

[0032] The special emulsion for composite rock slices of the present invention includes water, styrene, butyl acrylate, methyl methacrylate, methacrylamide, acrylic acid, ammonium dodecyl diphenyl oxide disulfonate, dodecyl polyoxygen Vinyl ether ammonium sulfate, alkyl sulfate, ammonium persulfate, potassium persulfate and sodium persulfate, the contents of the above components are calculated by mass percentage: water 50%, styrene 12%, butyl acrylate 22%, methyl Methyl acrylate 5%, methacrylamide 5%, acrylic acid 4%, ammonium dodecyl diphenyl oxide disulfonate 0.4%, ammonium lauryl polyoxyethylene ether sulfate 0.5%, alkyl sulfate 0.5%, ammonium persulfate 0.2%, potassium persulfate 0.2%, sodium persulfate 0.2%.

[0033] The preparation method of composite rock slice special emulsion of the present invention comprises the following steps:

[0034] a: Preparation of base liquid A: Add 30% of the total amount of water and 0.1% of surfactant to the reactor equipped with a stirr...

Embodiment 2

[0041] The special emulsion for composite rock slices of the present invention includes water, styrene, butyl acrylate, methyl methacrylate, methacrylamide, acrylic acid, dioctyl sulfosuccinate, dodecyl diphenyl oxide di Ammonium sulfonate, sodium lauryl diphenyl oxide disulfonate, ammonium lauryl polyoxyethylene ether sulfate, sodium laureth sulfate, alkyl sulfate and ammonium persulfate, above The component contents are calculated by mass percentage: water 50%, styrene 12%, butyl acrylate 27%, methyl methacrylate 5.9%, methacrylamide 2%, acrylic acid 1%, dioctyl sulfobutyl Diacid salt 0.4%, ammonium dodecyl diphenyl oxide disulfonate 0.3%, sodium dodecyl diphenyl oxide disulfonate 0.3%, ammonium lauryl polyoxyethylene ether sulfate 0.3% , Sodium Laureth Sulfate 0.3%, Alkyl Sulfate 0.4%, Ammonium Persulfate 0.1%.

[0042] The preparation method of composite rock slice special emulsion of the present invention comprises the following steps:

[0043] a: Preparation of base li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com