Counting machine, working method of counting machine, and packaging production line using the counting machine

A counting machine and computer technology, applied in the field of counting machines, can solve the problem of unsupplemented materials, etc., and achieve the effects of reducing impact, precise control, and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

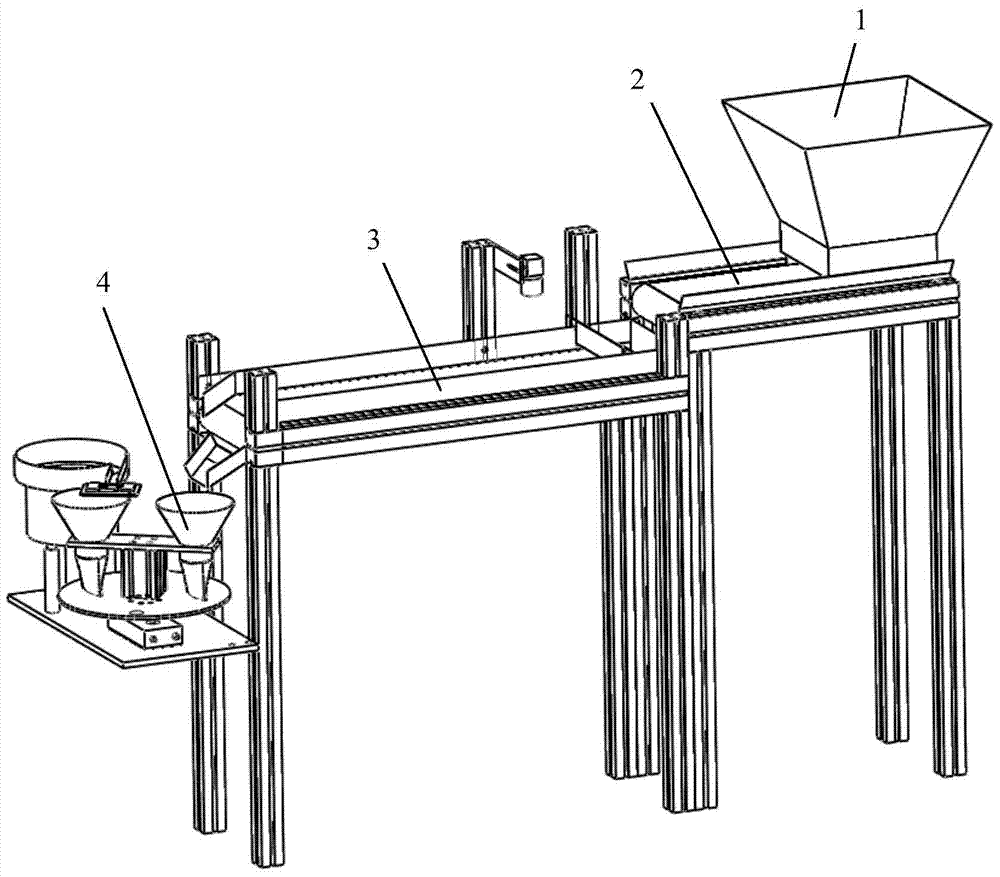

[0033] Such as Figure 1-4 As shown, the counting machine includes: a hopper 1, a primary conveyor belt 2, a secondary conveyor belt 3, a receiving and feeding mechanism 4 and a computer for intelligent control; the receiving and feeding mechanism 4 includes a vibration plate 11, a light curtain sensor 13, Hopper 14, packaging bag 15 and rotating frame 16.

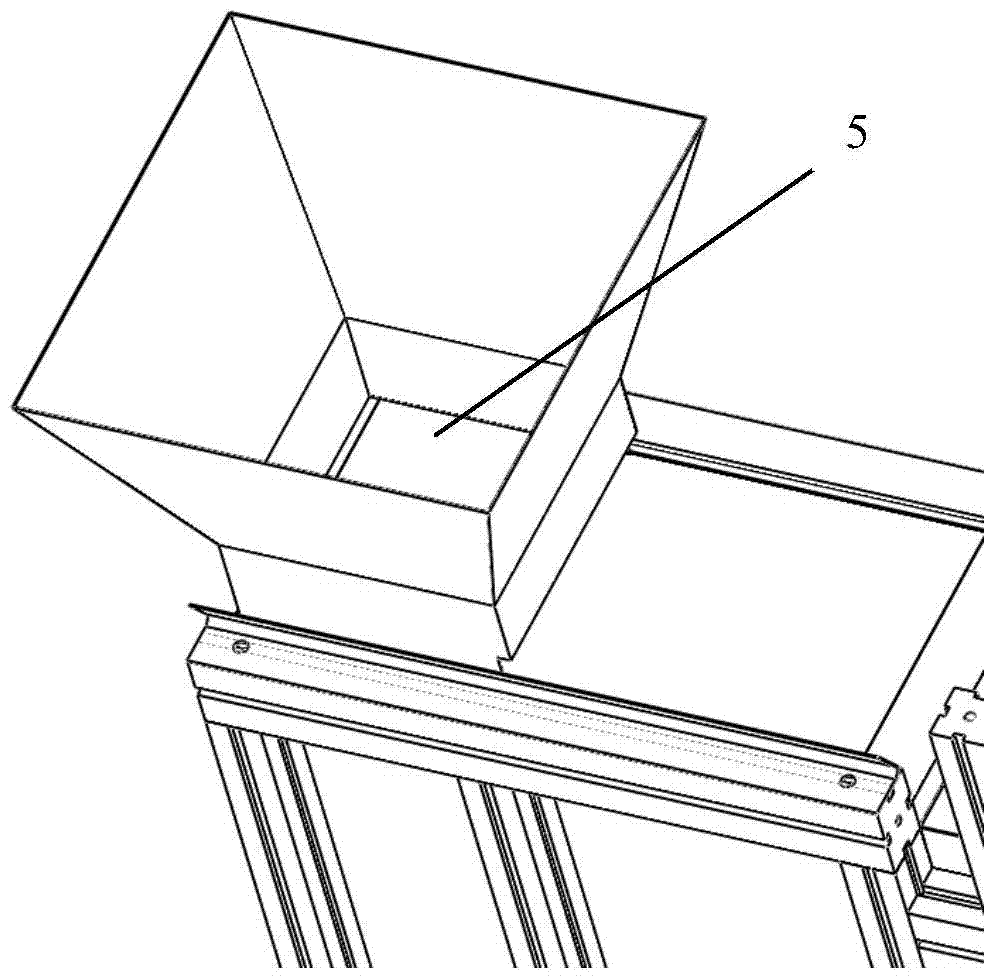

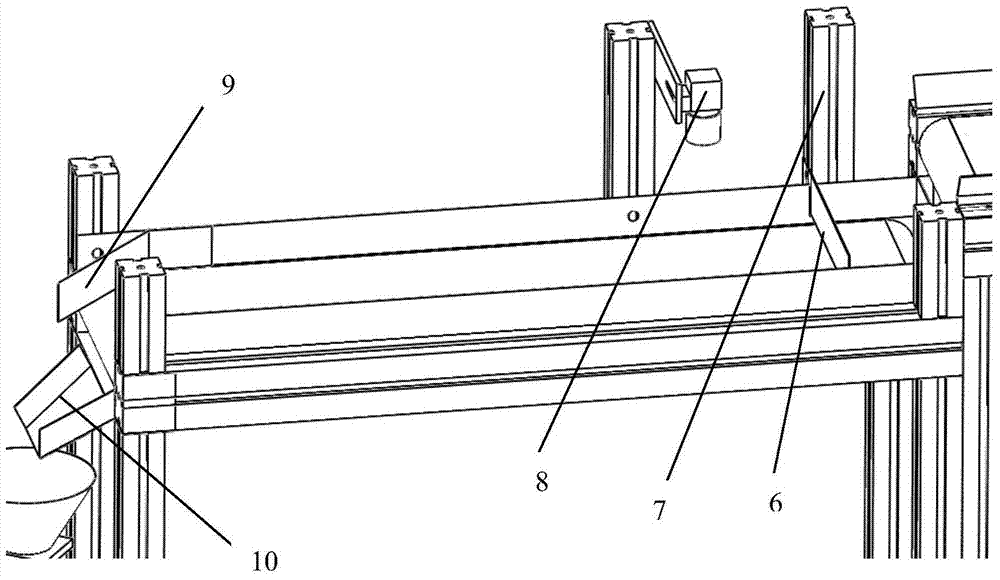

[0034] A hopper 1 is provided on the upper side of the beginning of the first-level conveyor belt 2. The top of the hopper 1 is an open material inlet, and its bottom is provided with an open material outlet 5. The material outlet 5 is facing the first-level conveyor belt 2, and the first-level conveyor belt 2 The beginning end of the secondary conveyor belt 3 is provided directly below the end of the secondary conveyor belt 3, and the moving speed of the working surface of the secondary conveyor belt 3 is twice the moving speed of the working surface of the primary conveyor belt 2. The material plate 6 and the material d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com