Method for repairing high-temperature alloy thin-walled cartridge receiver part through precision pulse welding

A technology of pulse welding and high temperature alloys, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of non-concentration of welding arc and deformation of parts, and achieve control of welding deformation, interlayer temperature, and reduction of welding stress level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

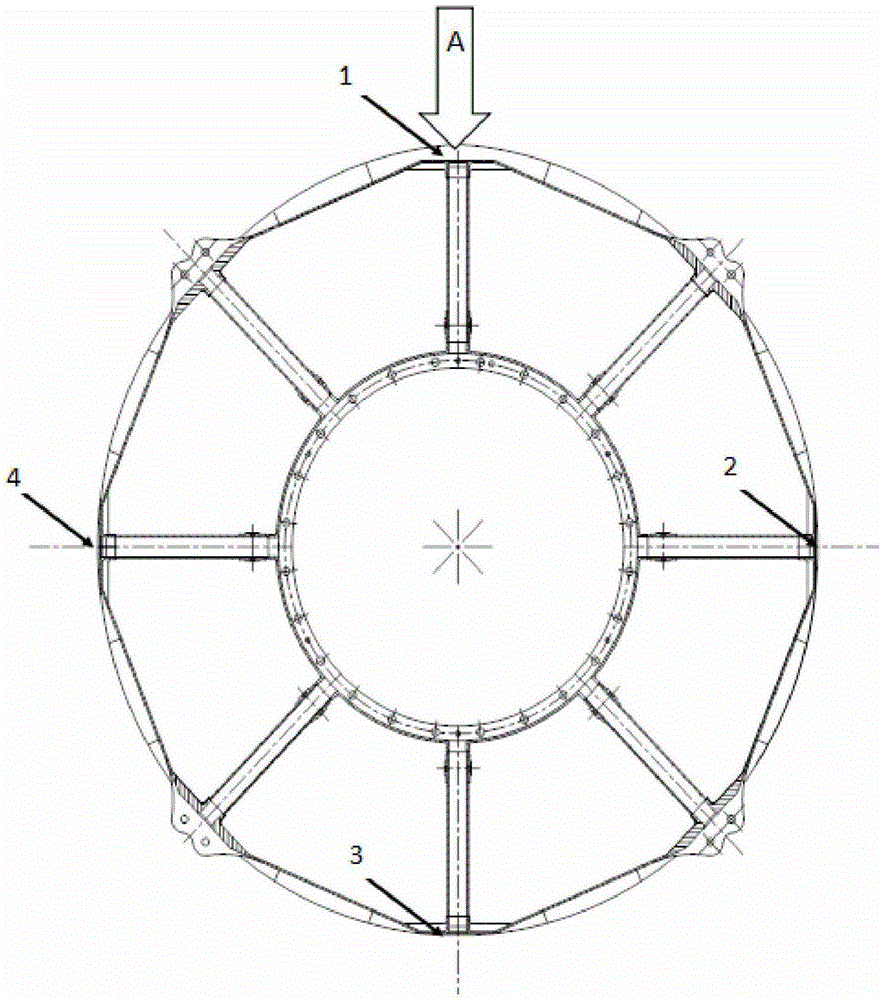

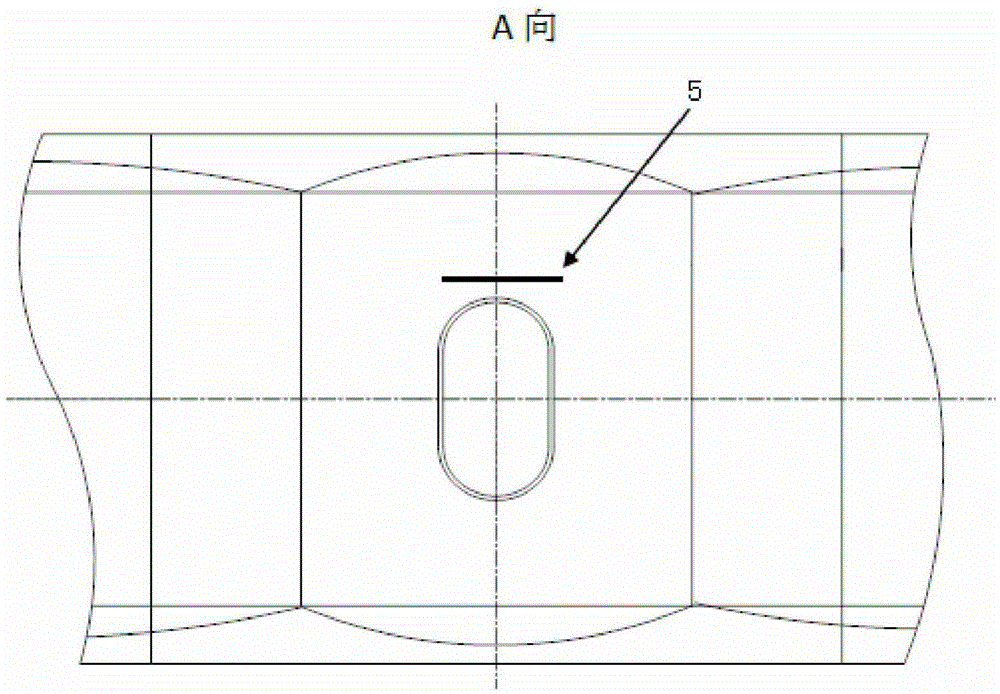

[0035] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

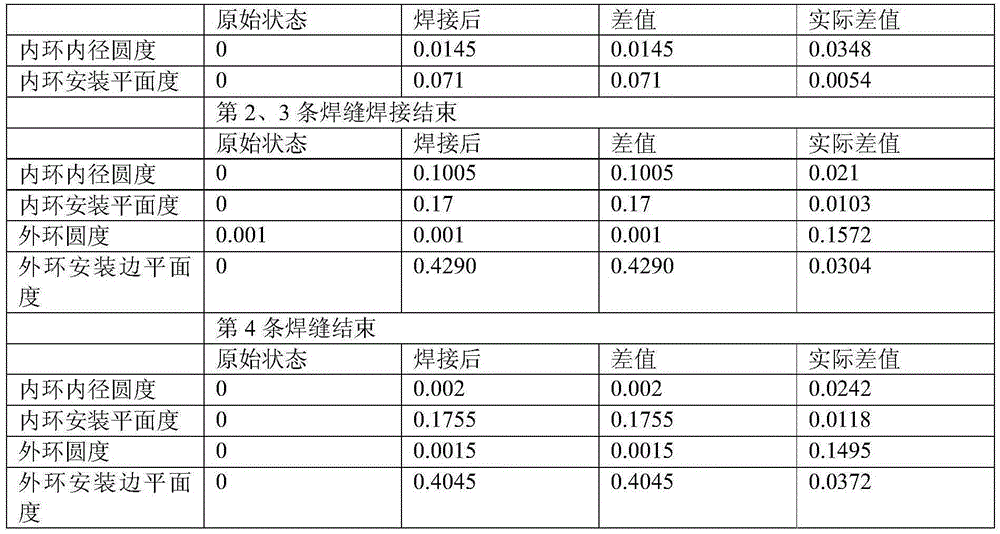

[0036] The method for repairing superalloy thin-wall casing parts by precision pulse welding in the present invention mainly includes: 1) predicting the welding deformation trend and analyzing the internal stress state of the parts after use; 2) reducing heat input and optimizing the welding process route; 3) Design special welding tooling to control parts deformation and welding pollution oxidation. Specifically include the following steps:

[0037] According to the defect length and position of thin-walled casing parts, combined with numerical simulation technology, the failure mode and stress state of parts are analyzed;

[0038] Accurately measure the front and rear mounting edges of the casing and other relevant dimensions before welding;

[0039] Use X-ray inspection and color inspection to determine defect location and size;

[0040] Proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com